Preparation method for super wear-resistant composite roll

A technology of composite rolls and rolls, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve problems such as spalling, and achieve the effects of solving surface stress, reducing consumption per ton of steel, and saving resources in roll manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The method for preparing a super wear-resistant composite roll of the present invention is composed of a roll core and a roll working layer or roll nest working layer. The roll material core is referred to as the roll core; the roll working layer or roll The nest working layer is prepared on the core of the roll by surfacing welding process, and is hardened by explosive hardening process or laser surface hardening process; the form of the roll is divided into two types: plate roll and profile roll.

[0034] The preparation method of the sheet roll includes the following steps:

[0035] Step 1) Use QT400--QT800-2 nodular cast iron cast plate roll material core, the core diameter is 5mm-50mm smaller than the final nominal diameter of the roll;

[0036] Step 2) Use a hollow electrode to surfacing the roller core to form a surfacing layer A on the surface of the roller core. The thickness of the surfacing layer A is 5-50mm; the hollow cavity of the hollow electrode contains...

Embodiment 1

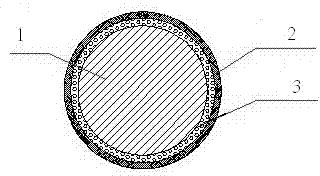

[0049] Such as figure 1 As shown, the method for preparing a sheet roll with a diameter of 1200mm

[0050] Step 1) Prepare the core of the sheet roll by casting method, the material is QT800-2. The core diameter is 1160 mm. The surface roughness Ra after rough machining is 32um.

[0051] Step 2) The surface of the roller core 1 needs to be heated to 290°C, and a hollow electrode is used to surfacing the roller core to form a surfacing layer A 3 on the surface of the roller core. The thickness of the surfacing layer A is 24mm; the hollow electrode cavity contains Composite powder, its composition is: 42CrMo powder, 65 nickel alloy powder, nano tungsten carbide powder, aluminum powder and graphite powder. The weight percentages are 50%, 20%, 8%, 20% and 2% respectively. The particle size of nano tungsten carbide is 80 nanometers, the particle size of graphite powder is -325 mesh, and the rest are all -200 mesh powder.

[0052] Step 3) Use high-energy directional explosive heat trea...

Embodiment 2

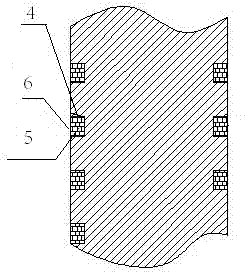

[0056] Such as figure 2 As shown, the method for preparing a profile roll with a diameter of 800mm

[0057] Step 1) Prepare the core of the sheet roll by casting method, the material is QT800-2. The core diameter is 795 mm. The surface roughness Ra after rough machining is 32um. The size of the reserved groove 4 is 50 mm in width and 40 mm in depth, and the distance between each reserved groove is 120 mm.

[0058] Step 2) Use a hollow electrode to surfacing the reserved groove 4, fill the reserved groove to form a surfacing layer B 5, the thickness of the surfacing layer B is 59 mm (that is, 19 mm higher than the surface of the core); Filling the reserved groove is the roller nest; the hollow cavity of the hollow electrode contains composite powder, and its composition is: 42CrMo powder, 65 nickel alloy powder, nano tungsten carbide powder, aluminum powder and graphite powder. The weight percentages are 45%, 25%, 12%, 15% and 3% respectively. The particle size of nano tungs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com