Wear-resistant shoe sole material for sneaker

A technology for sole materials and sports shoes, applied in soles, footwear, applications, etc., can solve the problems of high density and inconvenient use of soles, and achieve the effects of low density, light use, and good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

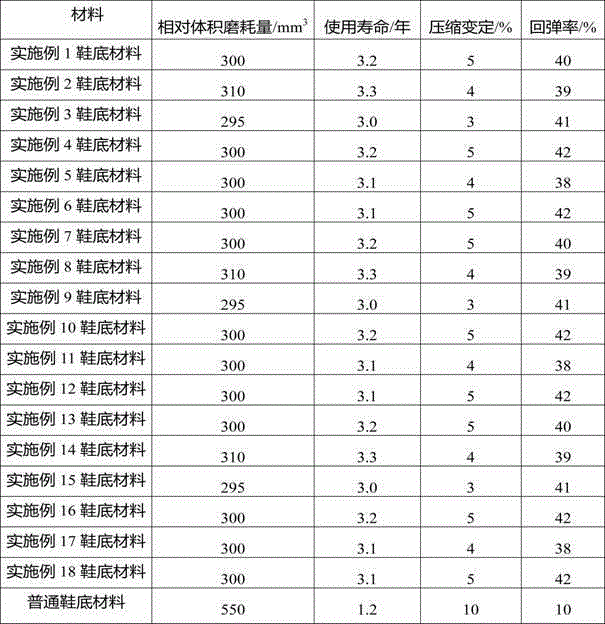

Examples

Embodiment 1

[0023] A wear-resistant sole material for sports shoes, the composition of which includes:

[0024] Lithopone 10kg, clay 5kg, carbon black 0.1kg, active zinc oxide 3kg, sulfur 2kg, stearic acid 1kg, nitrile rubber 70kg, collagen fiber 5kg, active zinc oxide 3kg, paraffin oil 2kg, polyethylene glycol 1kg, 5kg of light calcium carbonate with a particle size of 80nm, 1kg of titanium dioxide, 30kg of petroleum resin, and 45kg of epoxy resin.

[0025] These materials are compounded, and the hardness of the sole material is 65, the wear scar length is 4.5mm, and the DIN wear is 50mm. 3 , Elongation at break 660%, tensile strength 15MPa, right-angle tear strength 55N / mm, thickness 1.5cm, density 1.25g / cm 3 .

Embodiment 2

[0027] A sole material for sports shoes, the composition of which includes:

[0028] Lithopone 15kg, clay 10kg, carbon black 1kg, active zinc oxide 5kg, sulfur 5kg, stearic acid 5kg, nitrile rubber 80kg, collagen fiber 10kg, active zinc oxide 5kg, paraffin oil 5kg, polyethylene glycol 3kg, granules 10kg of light calcium carbonate with a diameter of 90nm, 5kg of titanium dioxide, 40kg of petroleum resin, and 55kg of epoxy resin.

[0029] By combining these materials, the hardness of the sole material is 66, the length of the wear scar is 4.6mm, and the DIN abrasion is 60mm. 3 , Elongation at break 670%, tensile strength 16MPa, right-angle tear strength 56N / mm, thickness 1.6cm, density 1.30g / cm 3 .

Embodiment 3

[0031] A sole material for sports shoes, the composition of which includes:

[0032] Lithopone 12.5kg, clay 7.5kg, carbon black 0.5kg, active zinc oxide 4kg, sulfur 3.5kg, stearic acid 3kg, nitrile rubber 75kg, collagen fiber 7.5kg, active zinc oxide 4kg, paraffin oil 3.5kg, poly 2kg of ethylene glycol, 7.5kg of light calcium carbonate with a particle size of 100nm, 3kg of titanium dioxide, 35kg of petroleum resin, and 50kg of epoxy resin.

[0033] By combining these materials, the hardness of the sole material is 67, the wear scar length is 4.7mm, and the DIN wear is 70mm. 3 , Elongation at break 680%, tensile strength 17MPa, right angle tear strength 57N / mm, thickness 1.7cm, density 1.35g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com