Cutting-grinding type impregnated diamond block and pdc composite disc mixed drill bit

A technology of impregnated diamond and impregnated blocks, which is applied in the field of cutting-grinding diamond and PDC composite sheet mixed drill bits, which can solve the problems of roller cone bits and diamond bits adapting to single formations, and avoid early collapse and avoid Stress concentration, avoiding the effect of anti-coring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

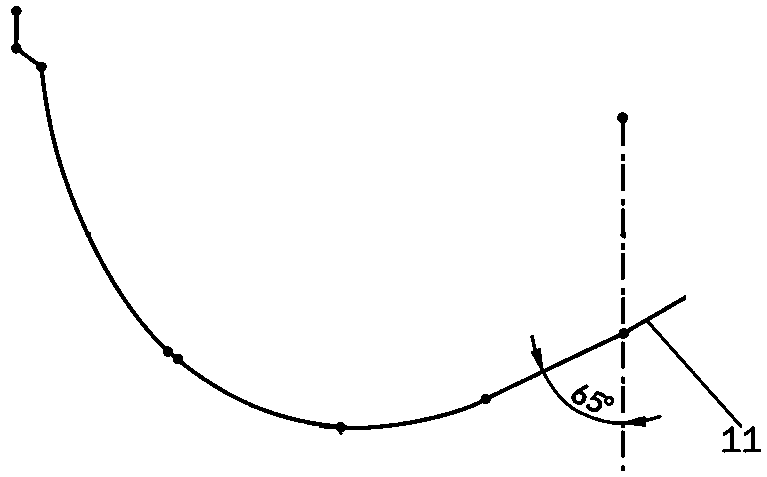

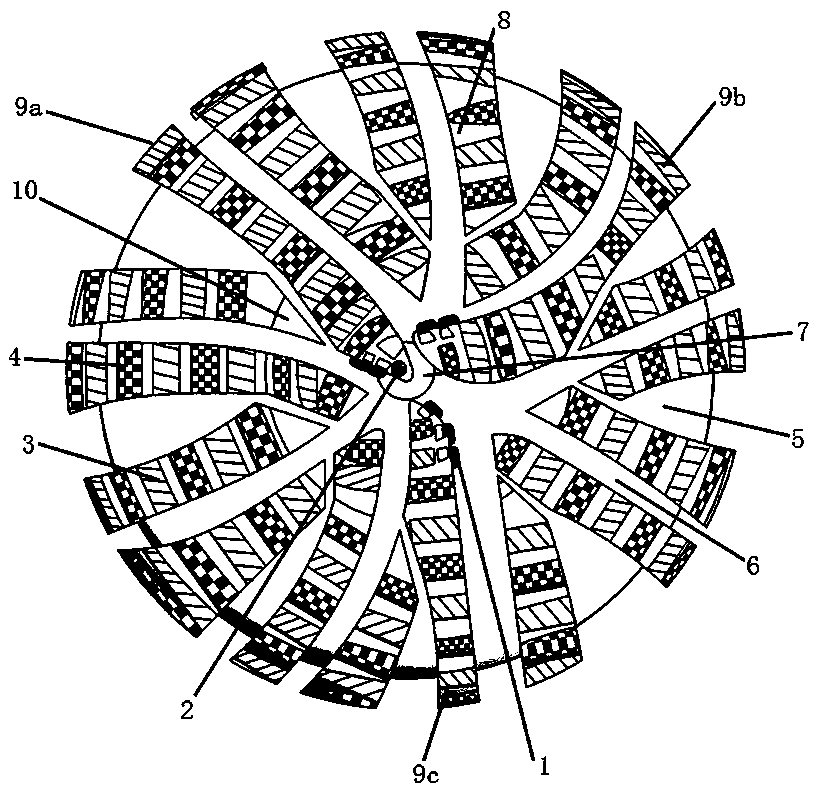

[0022] combine figure 1 , figure 2 , Figure 7 As shown, this cutting-grinding type impregnated diamond block and PDC composite sheet mixed drill bit is a blade-type drill bit. In order to ensure the stability and service life of the blade blade of the drill bit and avoid early stress concentration collapse, the trapezoidal Blade 8, crown section shape is straight-arc-arc type double-cone crown section, using 4 kinds of cutting teeth, which are two kinds of diamond-impregnated blocks with different carcass hardness and diamond concentration (the first impregnated Block 3, the second pregnant block 4, see the first pregnant block Figure 5 , see the second pregnancy insert Image 6 ), cylindrical PDC tooth 1 and circular wedge PDC tooth 2. The diamond particle size of the impregnated diamond blade matrix 10 is 46 mesh, the concentration is 80%, and the matrix hardness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com