Surfacing reconstructed layer of large hot-rolled supporting roll Cr4 and method for repairing roll

A back-up roll and roll technology, which is applied in rolls, welding media, metal rolling, etc., can solve the problems of phase transition between the parent metal and the surfacing layer, large roll diameter, and thick wear-resistant layer, and achieve broad application prospects and economical Benefits, excellent matrix bonding strength, simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

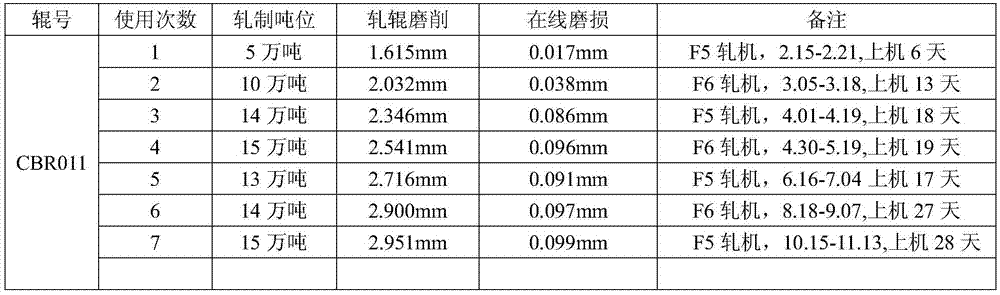

Embodiment 1

[0049] In this embodiment, the scrapped 1450 hot 7-rolling F5-F6 back-up roll with a diameter of 1420 mm and a material of Cr4 hot-rolled back-up roll (roll number: CBR011) is used as the substrate, and the reconstruction layer is surfacing on the surface of the substrate. The reconstruction layer From the surface of the substrate to the outside, it is composed of a primer layer, a transition layer and a working layer. In this embodiment, the primer flux-cored wire is prepared according to the alloy element composition of the large hot-rolled back-up roll Cr4, and the alloy elements of the primer flux-cored wire contain the following components by weight percentage: C0.06, Si0.5, P / s0.02, Mn1.4, Cr14, Mo+Ni+V+W+Ti1.2, the balance is Fe; the hardness of the bottom layer is HSD44. The transition layer flux-cored wire is prepared according to the alloy element composition of the primer layer, and the alloy elements of the transition layer flux-cored wire contain the following we...

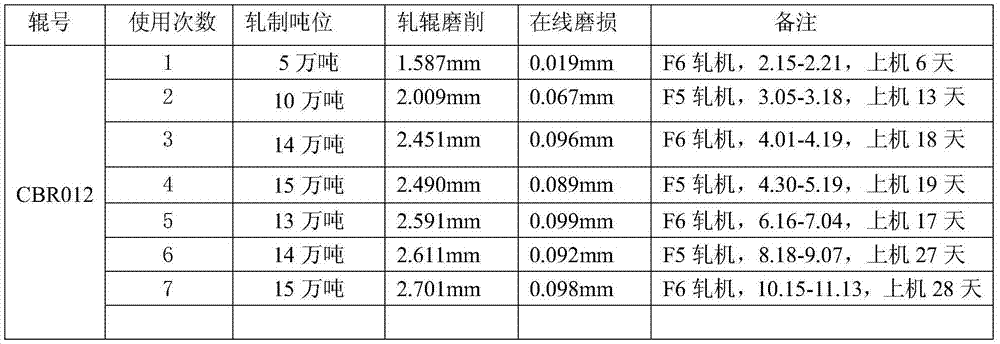

Embodiment 2

[0093] In this embodiment, the scrapped 1450 hot 7 continuous rolling F5-F6 back-up roll with a diameter of 1420mm and material Cr4 hot-rolled back-up roll (roll number: CBR012) was used as the substrate, and the repaired and reconstructed layer was surfacing on the surface of the substrate. The reconstruction layer is composed of a base layer, a transition layer and a working layer sequentially from the surface of the substrate. In this embodiment, the primer flux-cored wire is prepared according to the alloy element composition of the large hot-rolled backup roll Cr4, and the alloy elements of the primer flux-cored wire contain the following components by weight percentage: C0.08, Si0.6, P / s0.03, Mn1.7, Cr13.5, other alloying elements Mo+Ni+V+W+Ti1.3, the balance is Fe; the hardness of the bottom layer is HSD46. The flux-cored welding wire of the transition layer is prepared according to the alloy element composition of the bottom layer, and the alloy elements of the transit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com