Polymer powder for 3D printing and preparation method of polymer powder

A 3D printing and polymer technology, applied in the field of polymer powder and its preparation, can solve the problems of high production cost, unsuitable for preparing human medical implant materials, complex production process, etc., achieve good molding effect, eliminate harm to human body and Environmental hazards and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

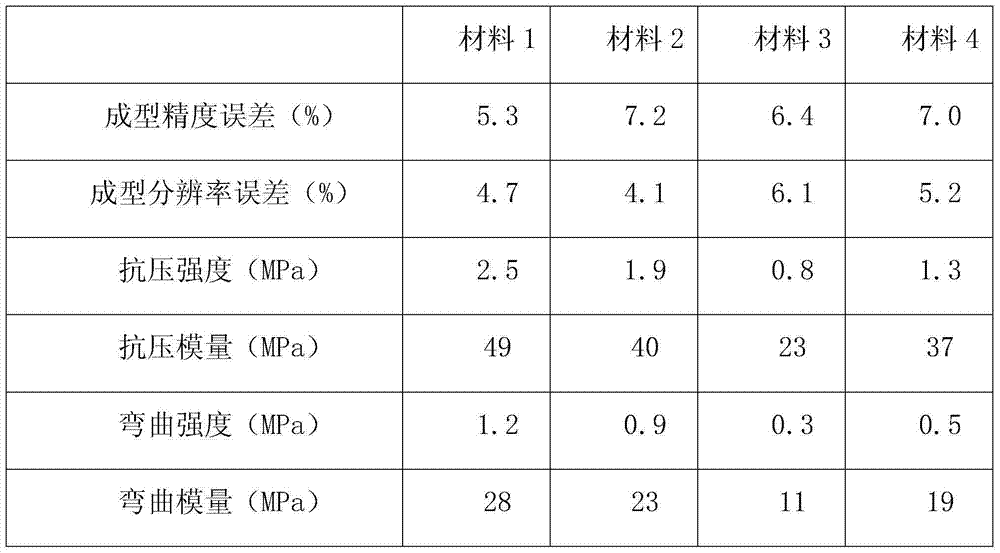

Embodiment 1

[0020] The formula is: comprising the following components by weight, 60 parts of polymethyl methacrylate, 30 parts of starch, 8 parts of methyl cellulose, and 2 parts of superfine silicon dioxide powder.

[0021] Preparation method: Mix 60 parts of polymethyl methacrylate, 30 parts of starch, 8 parts of methyl cellulose and 2 parts of superfine silicon dioxide powder, then fully stir at room temperature until the mixture is uniform to obtain a molding powder Material 1.

Embodiment 2

[0023] The formula is: comprising the following components by weight, 50 parts of polystyrene, 35 parts of maltodextrin, 8 parts of sodium carboxymethyl cellulose, and 7 parts of superfine aluminum oxide powder.

[0024] Preparation method: Mix 50 parts of polystyrene, 35 parts of maltodextrin, 8 parts of sodium carboxymethyl cellulose and 7 parts of superfine aluminum oxide powder, then fully stir at room temperature until the mixture is uniform. Molded powder material 2.

Embodiment 3

[0026] The formula is: comprising the following components by weight, 30 parts of polymethyl methacrylate and 10 parts of polyvinyl alcohol.

[0027] Preparation method: Mix 30 parts of polymethyl methacrylate and 10 parts of polyvinyl alcohol, and then fully stir at room temperature until the mixture is uniform to prepare the molding powder material 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com