Foaming shoe midsole material made of TPEE material and preparation process thereof

A material and foaming agent technology, applied in the field of shoe material foaming midsole, can solve the problems of large pores, open pores or uneven pore size, low melt strength, etc., and achieve stable microcellular structure, strong weather resistance, The effect of good recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

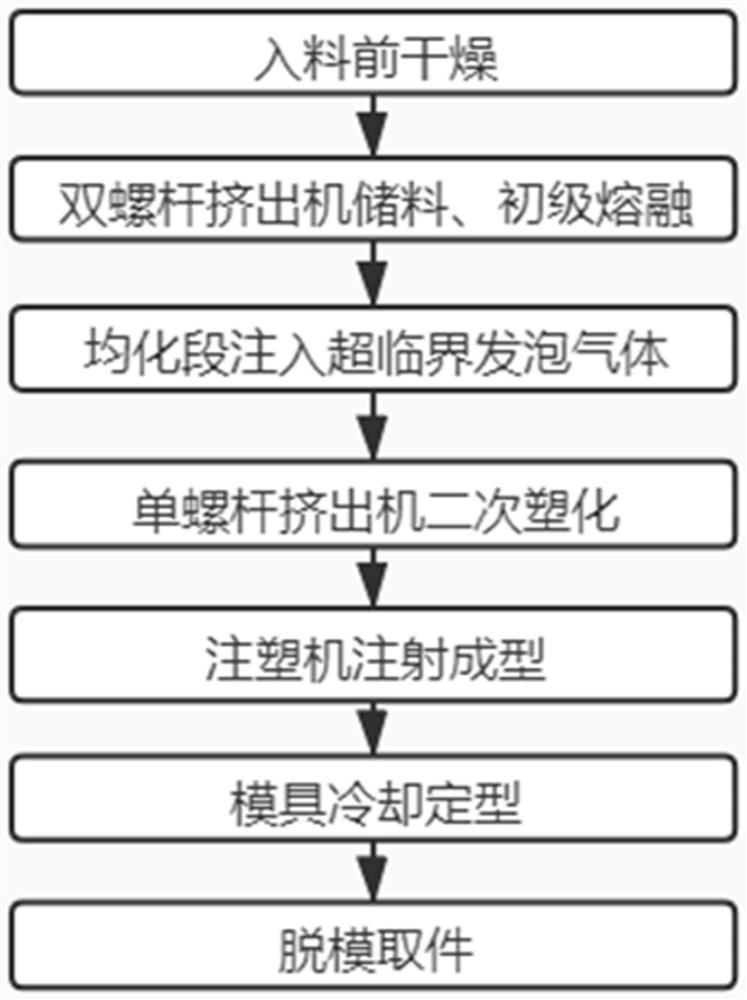

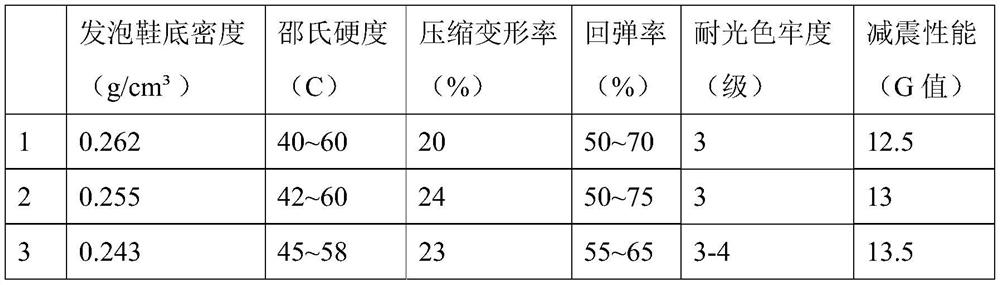

[0041] The invention discloses a foam shoe midsole material made of TPEE, which comprises the following steps:

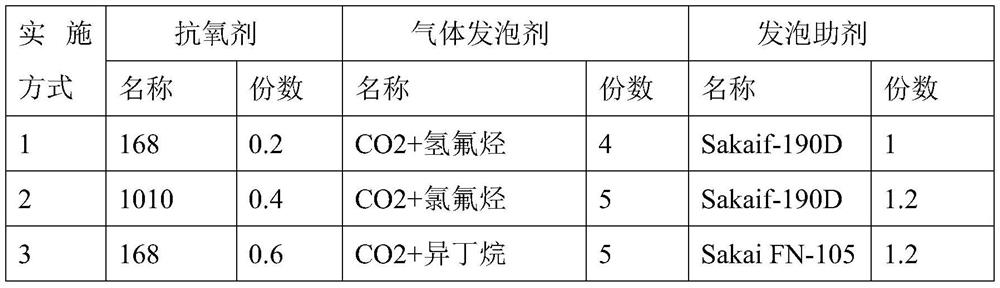

[0042] Raw materials: 85 parts of thermoplastic polyester elastomer, 3.4 parts of talc powder as lubricant and nucleating agent, 0.4 part of cell stabilizer, 1.0 part of DCP, and the names and parts of the remaining additives are shown in Table 1 shown.

[0043] Table 1 embodiment uses name and raw material parts

[0044]

[0045] After drying TPEE particles in a vacuum oven at 80°C for 3 hours, mix them with additives and pass them through a weight-loss precision feeder at a constant rate of 120cm 3 / s blanking, the material is plasticized through the twin-screw extruder, and is initially melted and mixed in the feeding section and the compression section. When entering the metering section, a supercritical fluid is injected into the foaming machine at a pressure of 8kpa to form a thermoplastic polyester. / Supercritical fluid two-phase system, which becomes a ...

Embodiment 2

[0049] The invention discloses a foam shoe midsole material made of TPEE, which comprises the following steps:

[0050] Raw materials: 95 parts of thermoplastic polyester elastomer, 1.2 parts of talc powder as lubricant, 2 parts of nucleating agent as a mixture of talc powder and wax powder, 1 part of cell stabilizer, 1.2 parts of DCP and BPO mixture, and the remaining additives The name of use and the number of parts of additives are shown in Table 3.

[0051] Table 3 embodiment use name and raw material parts

[0052]

[0053] After drying TPEE particles in a vacuum oven at 90°C for 2 hours, mix them with additives and pass them through a weight-loss precision feeder at a constant rate of 150cm 3 / s blanking, the material is plasticized through the twin-screw extruder, and is initially melted and mixed in the feeding section and the compression section. When entering the metering section, a supercritical fluid is injected into the foaming machine at a pressure of 6kpa to...

Embodiment 3

[0057] The invention discloses a foam shoe midsole material made of TPEE, which comprises the following steps:

[0058] Raw materials: 100 parts of thermoplastic polyester elastomer, 2.2 parts of non-polar PE wax as lubricant, 3 parts of wax powder as nucleating agent, 2 parts of cell stabilizer, 2 parts of BIPB, the names and additives of the remaining additives The number of copies is shown in Table 5.

[0059] Table 5 embodiment uses name and raw material parts

[0060]

[0061] After drying TPEE particles in a vacuum oven at 80°C for 2 hours, mix them with additives and pass them through a weight-loss precision feeder at a constant rate of 150cm 3 / s blanking, the material is plasticized through the twin-screw extruder, and is initially melted and mixed in the feeding section and the compression section. When entering the metering section, a supercritical fluid is injected into the foaming machine at a pressure of 8kpa to form a thermoplastic polyester. / Supercritical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com