Investment cast shell crushing, grading and screening system

A technology of graded screening and investment casting, which is applied to casting molding equipment, machinery for cleaning/processing mold materials, manufacturing tools, etc., can solve problems such as waste of resources, slow work efficiency of workers, and impact on workers' physical and mental health, and achieve Low noise, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

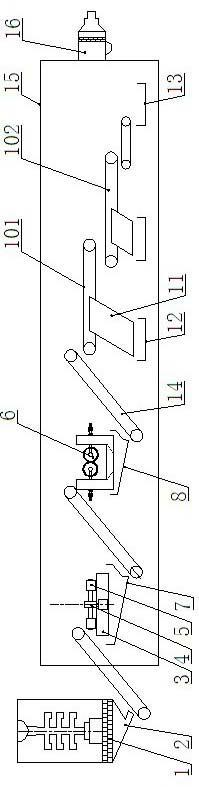

[0017] Such as figure 1 As shown, the present invention relates to a device capable of classifying and screening recycled investment casting sand, comprising

[0018] A vibrating sand cleaning mechanism, which includes a screen 1 on which a vibrator is installed, and a shakeout collecting bucket 2 is arranged at the bottom of the screen 1 .

[0019] A grinding and crushing mechanism includes a grinding plate 3, on which a vertical rotating shaft 4 driven by a motor is arranged, a pair of rollers 5 are arranged on the rotating shaft 4, and a falling sand collecting bucket 7 is arranged under the grinding plate 3.

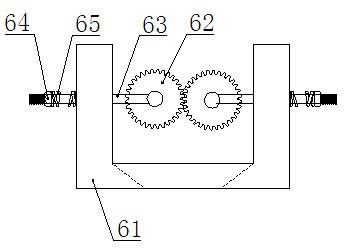

[0020] A gear-to-roll mechanism 6, such as figure 2 As shown, a gear frame 61 is included, and a pair of mutually meshing gears 62 are installed on the gear frame 61. The gear 62 is installed on the gear frame 61 through a horizontally arranged guide rod 63, and the guide rod 63 is slidably matched with the gear frame 61 to guide The threaded end of the rod 63 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com