Thread turning process parameter optimization method for green manufacturing

A technology of process parameter optimization and green manufacturing, which is applied in the field of mechanical cutting to achieve the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

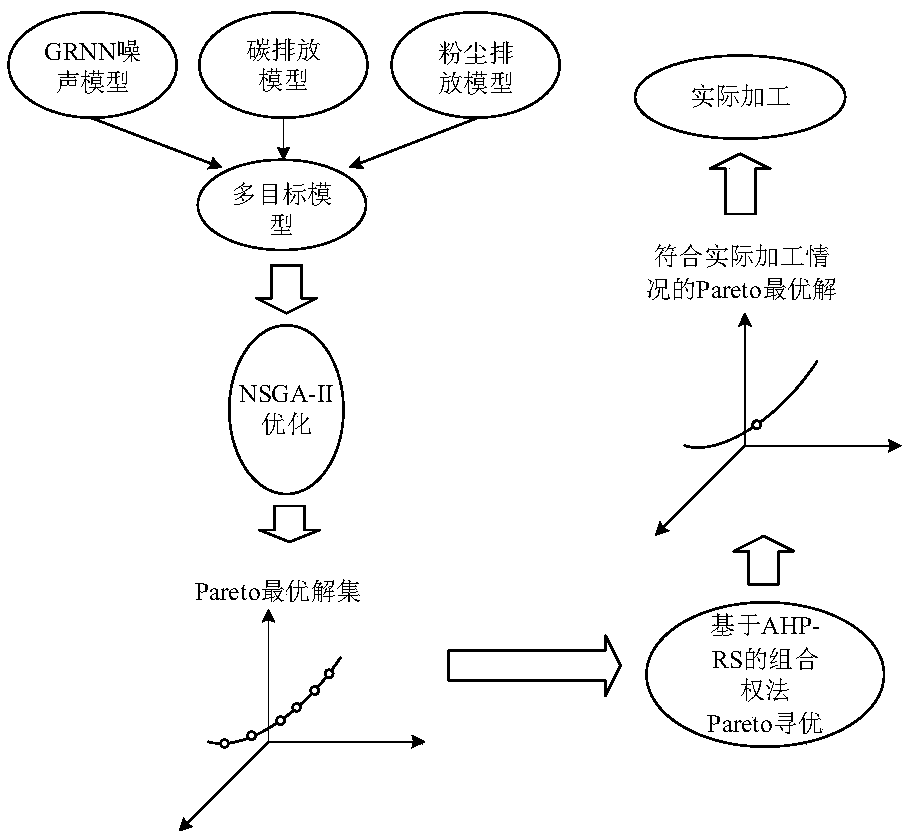

[0091] A method for optimizing thread turning process parameters for green manufacturing, comprising the following steps: (1) determining the optimization variable: cutting speed V during thread turning c and feed f;

[0092] (2) Establish a multi-objective optimization function;

[0093] (3) Determine the constraints;

[0094] (4) The objective function is optimized to obtain its Pareto optimal solution set, such as image 3 shown;

[0095] (5) Obtain the weight of each objective function through the combined weight determination method based on AHP and rough set theory RS, and obtain the optimal solution from the optimal solution set in step (4).

[0096] The establishment of multi-objective optimization function described in step (2) specifically includes the following steps:

[0097] 1) Establish a multi-objective optimization function including carbon emissions, machine tool noise and dust emissions;

[0098] Among them, the carbon emission function model is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com