Cold extrusion forming method of axisymmetric pull rod joint part

A cold extrusion, axisymmetric technology, used in metal extrusion, metal extrusion cleaning equipment, metal processing equipment, etc., can solve problems such as not meeting urgent requirements, affecting product quality, reducing deformation resistance, etc. Low cost, low production cost and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

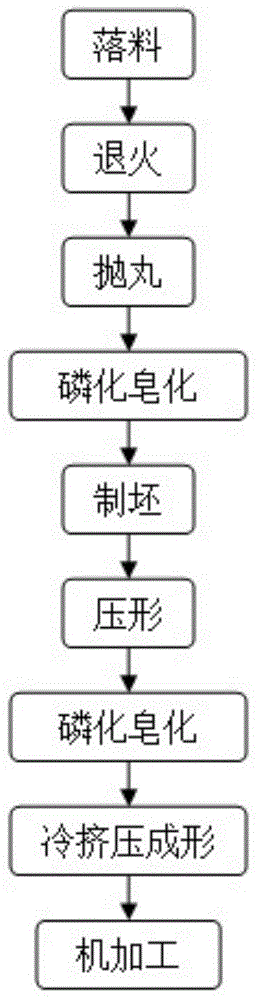

[0033] A cold extrusion forming method of axisymmetric tie rod joint parts, the process is as follows figure 1 As shown, it includes blanking, annealing, shot blasting, phosphating saponification, billet making, pressing, phosphating saponification, cold extrusion molding, and machining processes, specifically including the following steps:

[0034] (1) Preparation of tie rod joint blank (blanking):

[0035] Calculating and determining the size of the blank before preparing the tie rod joint blank in step (1), cutting the round steel by sawing to obtain the tie rod joint blank;

[0036] (2) Anneal the blank to soften it (annealing):

[0037] The process conditions are: under the protection of nitrogen atmosphere, heat preservation at 860°C for 8 hours, and then cool down to below 450°C with the furnace;

[0038] (3) Shot blasting the annealed blank to eliminate burrs and scale (shot blasting):

[0039] The process conditions are: use pellets with a diameter of 0.6-1.0mm to ...

Embodiment 2

[0053] A cold extrusion forming method of axisymmetric tie rod joint parts, the process is as follows figure 1 As shown, it includes blanking, annealing, shot blasting, phosphating saponification, billet making, pressing, phosphating saponification, cold extrusion molding, and machining processes, specifically including the following steps:

[0054] (1) Preparation of tie rod joint blank (blanking):

[0055] Calculating and determining the size of the blank before preparing the tie rod joint blank in step (1), cutting the round steel by sawing to obtain the tie rod joint blank;

[0056] (2) Anneal the blank to soften it (annealing):

[0057] The process conditions are: under the protection of nitrogen atmosphere, heat preservation at 880°C for 7 hours, and then cool down to below 450°C with the furnace;

[0058] (3) Shot blasting the annealed blank to eliminate burrs and scale (shot blasting):

[0059] The process conditions are: use pellets with a diameter of 0.6-1.0mm to tr...

Embodiment 3

[0072] A cold extrusion forming method of axisymmetric tie rod joint parts, the process is as follows figure 1 As shown, it includes blanking, annealing, shot blasting, phosphating saponification, billet making, pressing, phosphating saponification, cold extrusion molding, and machining processes, specifically including the following steps:

[0073] (1) Preparation of tie rod joint blank (blanking):

[0074] Calculating and determining the size of the blank before preparing the tie rod joint blank in step (1), cutting the round steel by sawing to obtain the tie rod joint blank;

[0075] (2) Anneal the blank to soften it (annealing):

[0076] The process conditions are: under the protection of nitrogen atmosphere, heat preservation at 900°C for 7 hours, and then cool to below 450°C with the furnace;

[0077] (3) Shot blasting the annealed blank to eliminate burrs and scale (shot blasting):

[0078] The process conditions are: use pellets with a diameter of 0.6-1.0mm to treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com