Multi-target cutting parameter optimization method for green manufacturing

A technology of cutting parameters and optimization methods, applied in the field of mechanical cutting, can solve problems such as difficult to meet, ignoring resource consumption and environmental emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

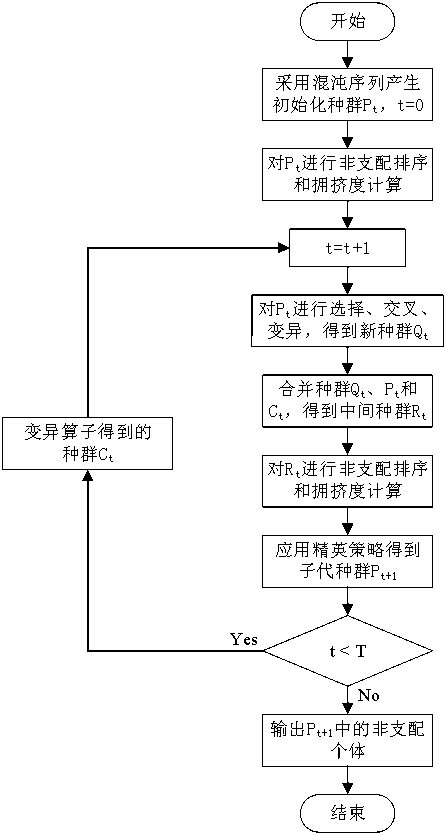

[0078] Please refer to figure 1 , the present invention provides a multi-objective cutting parameter optimization method for green manufacturing, comprising the following steps:

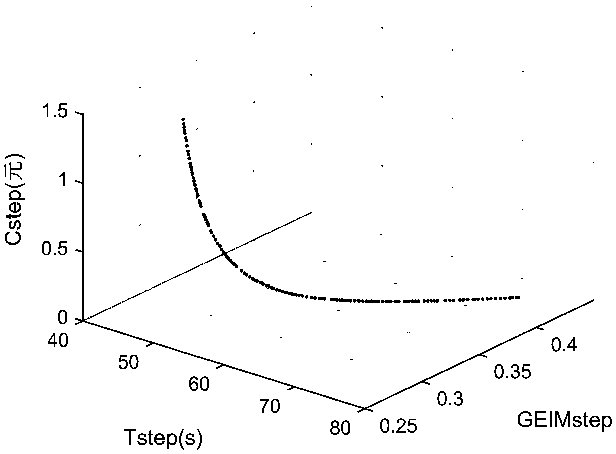

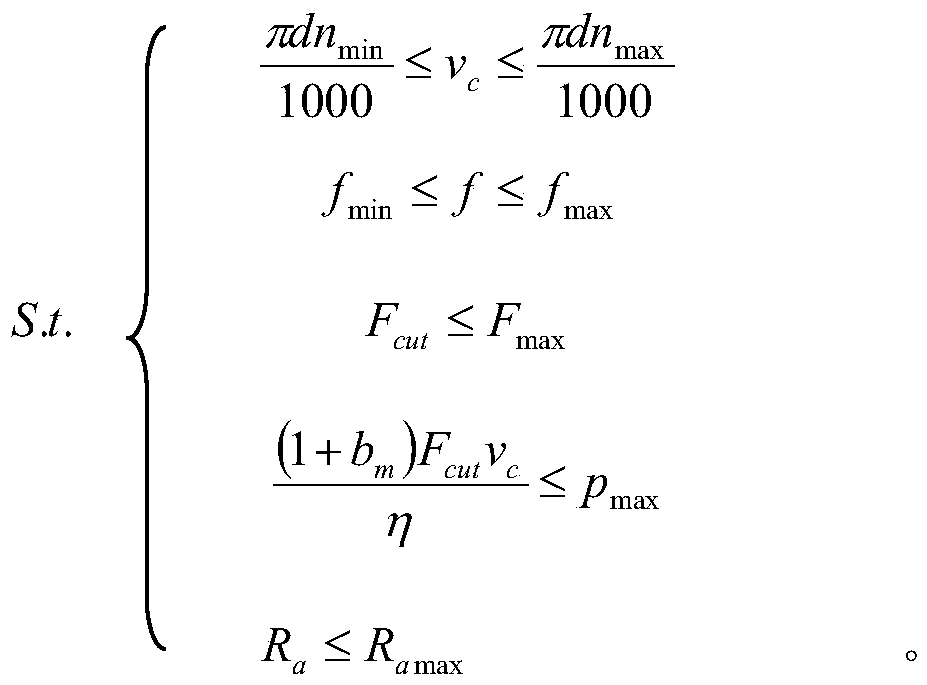

[0079] (1) According to the processing status of a single step in the cutting process, the cutting speed v c , feed f as the optimization variable, respectively establish the objective function T of machining time optimization step , the green evaluation index function GEIM of mechanical processing that comprehensively considers the energy consumption of machine tools and cutting fluid consumption step , and the objective function C of machining cost optimization step ;

[0080] The establishment process of each optimization objective function is as follows:

[0081] (1.1) Take the cutting speed v in the cutting processing system c , feed f as the optimization variable, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com