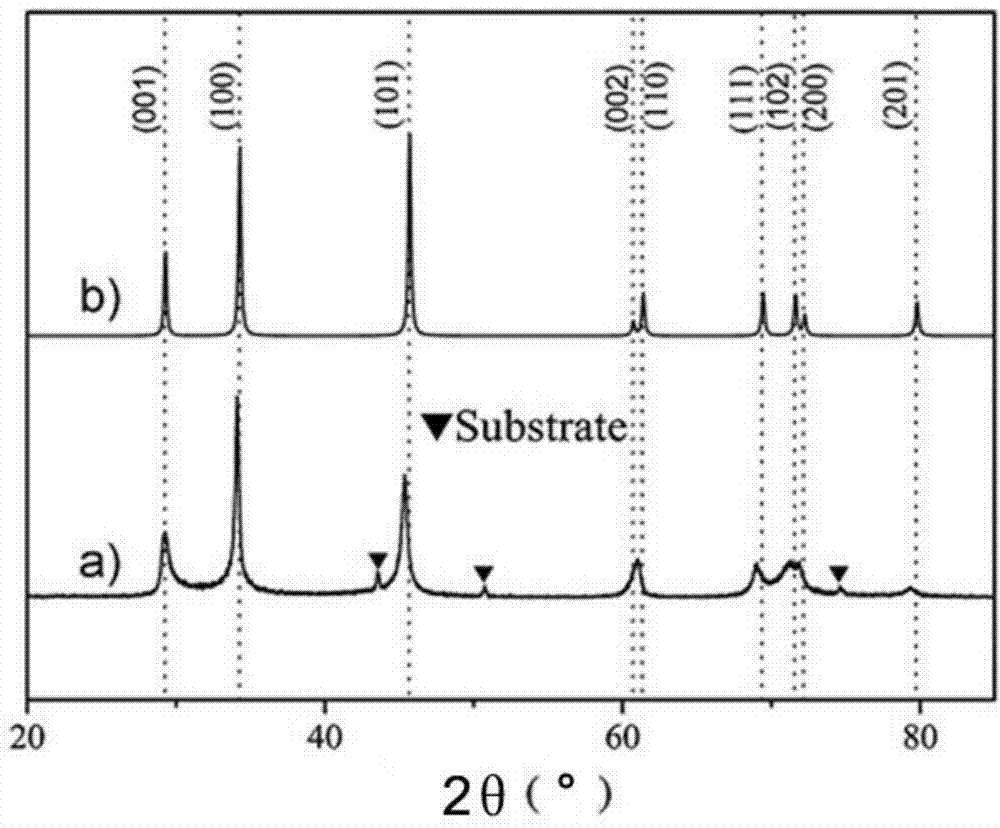

AlB2 type WB2 hard coating and preparation technology thereof

A technology of hard coating and preparation process, which is applied in the field of depositing hard wear-resistant coating on the surface of metal materials, which can solve the problem of less film/coating, achieve good friction and wear performance, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

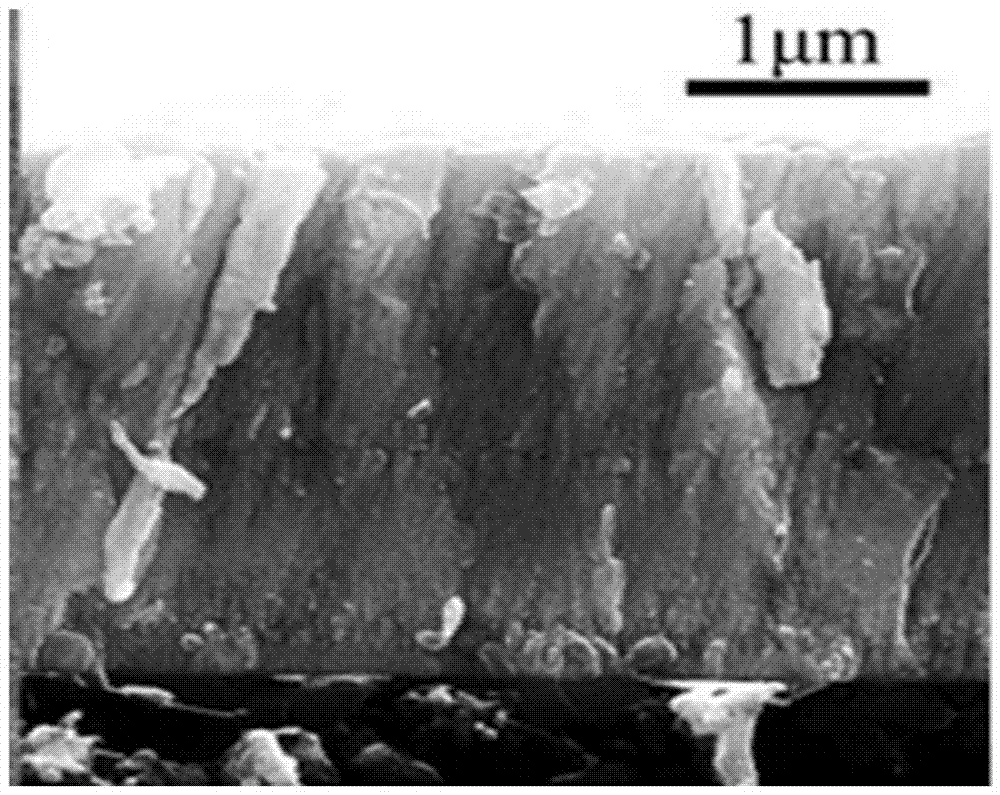

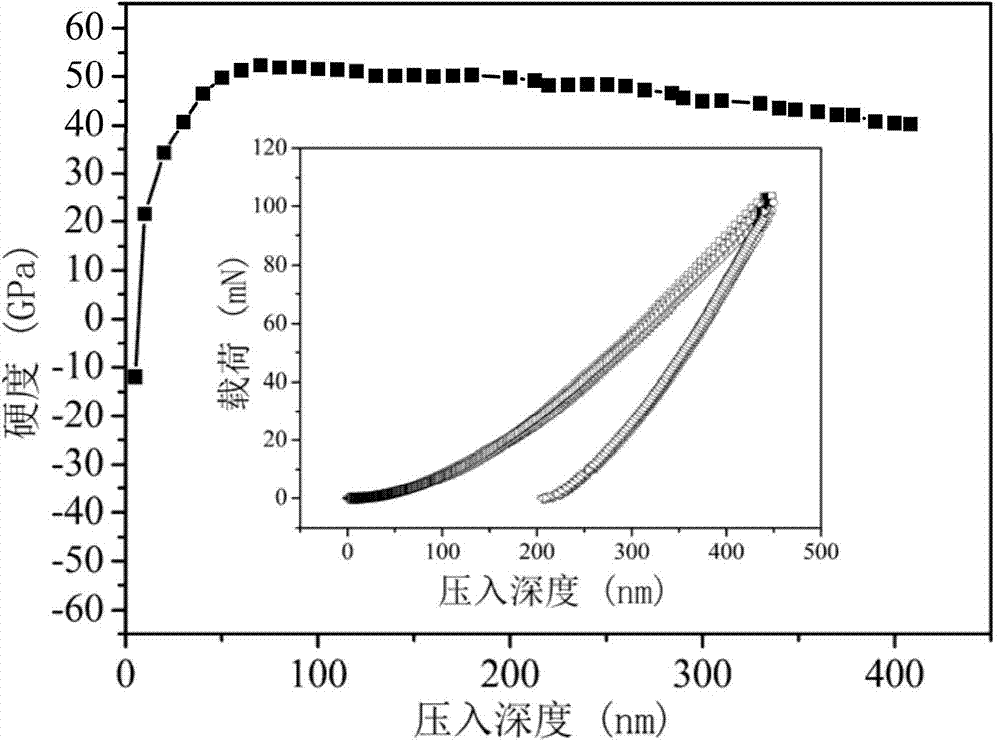

Embodiment 1

[0023] The base material is high-speed steel (grade W18Cr4V), and the sample size is 270mm×70mm×7mm. The surface before coating is ground, polished, ultrasonically cleaned and dried, and then placed on the sample stage of the vacuum chamber until the vacuum degree in the vacuum chamber reaches 5×10 -3 At Pa, turn on the gas mass flow controller, pass argon to 2.0Pa, add the substrate bias to -180V, and perform glow cleaning on the sample for 15 minutes. After that, enter the thin film deposition process, the specific process parameters are: the target base distance is 50mm, the set air pressure is 0.3Pa, the target voltage is 360V, the current is 0.5A, the substrate bias is -180V, the duty cycle is 30%, and the deposition temperature is 680°C , with a total deposition time of 120 min. After the deposition is completed, quickly reduce the bias voltage, turn off the power switch of the sputtering target, stop the gas, continue to vacuumize, and when the furnace cools until the ...

Embodiment 2

[0029] The base material is cemented carbide (grade YG6), and the sample size is 20mm×20mm×3mm. The surface before coating is ground, polished, ultrasonically cleaned and dried, and then placed on the sample stage of the vacuum chamber until the vacuum degree in the vacuum chamber reaches 5×10 -3 At Pa, turn on the gas mass flow controller, pass argon to 0.8Pa, add the substrate bias to -180V, and perform glow cleaning on the sample for 10 minutes. After that, the thin film deposition process is entered. The specific process parameters are: the target base distance is 70mm, the set air pressure is 0.5Pa, the target voltage is 380V, the current is 0.8A, the substrate bias is -50V, the duty cycle is 25%, and the deposition temperature is 400°C. °C, and the total deposition time was 80 minutes. After the deposition is completed, quickly reduce the bias voltage, turn off the power switch of the sputtering target, stop the gas, continue to vacuumize, and when the furnace cools unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com