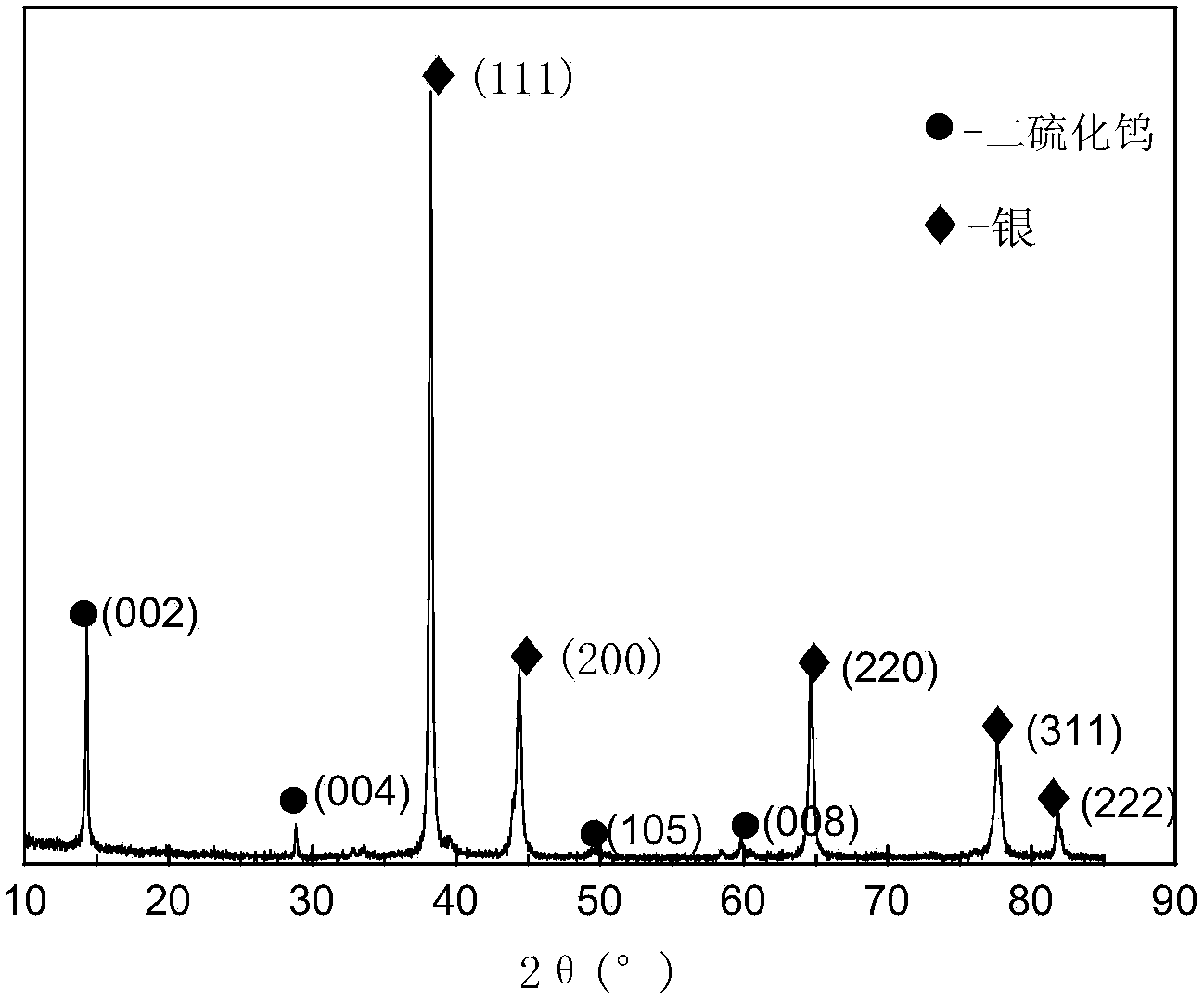

Electric brush-sliding ring system made of silver-tungsten disulfide composite materials

A technology of tungsten disulfide and composite materials, applied in the field of brush material modification, can solve the problems of low energy consumption and short service life, and achieve the effects of low energy consumption, long service life and small variation range of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0024] Mix 76% Ag-2.5Cu alloy powder (-400 mesh) and 24% WS by mass percentage 2 The powder (particle size 600-800nm) is evenly mixed, and then the silver-tungsten disulfide composite brush is prepared according to the powder metallurgy hot-pressing method, the hot-pressing temperature is 900-920°C, the target pressure is 25MPa, the holding time is 25min, and the protective atmosphere is nitrogen or argon gas. The relative density of the brush prepared by the above formula and process is 99.4%, the hardness (HB) is 70.5, and the resistivity is 5.43×10 -8 Ω m; under the conditions of load 5N and sliding speed 0.21m / s, the volumetric wear rate is 8.0×10 when paired with AgCu10 slip ring (diameter 50mm) -15 m 3 / N·m, the service life is greater than 600,000 revolutions, the static contact resistance is <0.65mΩ, and the average friction coefficient is 0.179.

Embodiment 3

[0026] According to the mass percentage, 72% Ag-2.5Cu alloy powder (-400 mesh) and 28% WS 2 The powder (particle size 600-800nm) is evenly mixed, and then the silver-tungsten disulfide composite brush is prepared according to the powder metallurgy hot-pressing method, the hot-pressing temperature is 900-920°C, the target pressure is 25MPa, the holding time is 25min, and the protective atmosphere is nitrogen or argon gas. The relative density of the brush prepared by the above formula and process is 99.6%, the hardness (HB) is 71.4, and the resistivity is 6.39×10 -8 Ω m; under the conditions of load 5N and sliding speed 0.21m / s, the volumetric wear rate is 7.5×10 when coupled with AgCu10 slip ring (diameter 50mm) -15 m 3 / N·m, the service life is greater than 650,000 revolutions, the static contact resistance is <0.65mΩ, and the average friction coefficient is 0.172.

Embodiment 4

[0028] Mix 76% Ag-3Cu alloy powder (-400 mesh) and 24% WS by mass percentage 2 The powder (particle size 600-800nm) is evenly mixed, and then the silver-tungsten disulfide composite brush is prepared according to the powder metallurgy hot-pressing method, the hot-pressing temperature is 900-920°C, the target pressure is 25MPa, the holding time is 25min, and the protective atmosphere is nitrogen or argon gas. The relative density of the brush prepared by the above formula and process is 98.2%, the hardness (HB) is 73.5, and the resistivity is 6.17×10 -8 Ω m; under the conditions of load 5N and sliding speed 0.21m / s, the volumetric wear rate is 7.4×10 when paired with AgCu10 slip ring (diameter 50mm) -15 m 3 / N·m, the service life is greater than 650,000 revolutions, the static contact resistance is <0.41mΩ, and the average friction coefficient is 0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com