Method for preparing copper silicon alloy modified carbon/ceramic friction material

A copper-silicon alloy and friction material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as increasing the angle between fibers and friction surfaces, decreasing material strength and fracture toughness, and increasing material manufacturing costs. Easy to process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

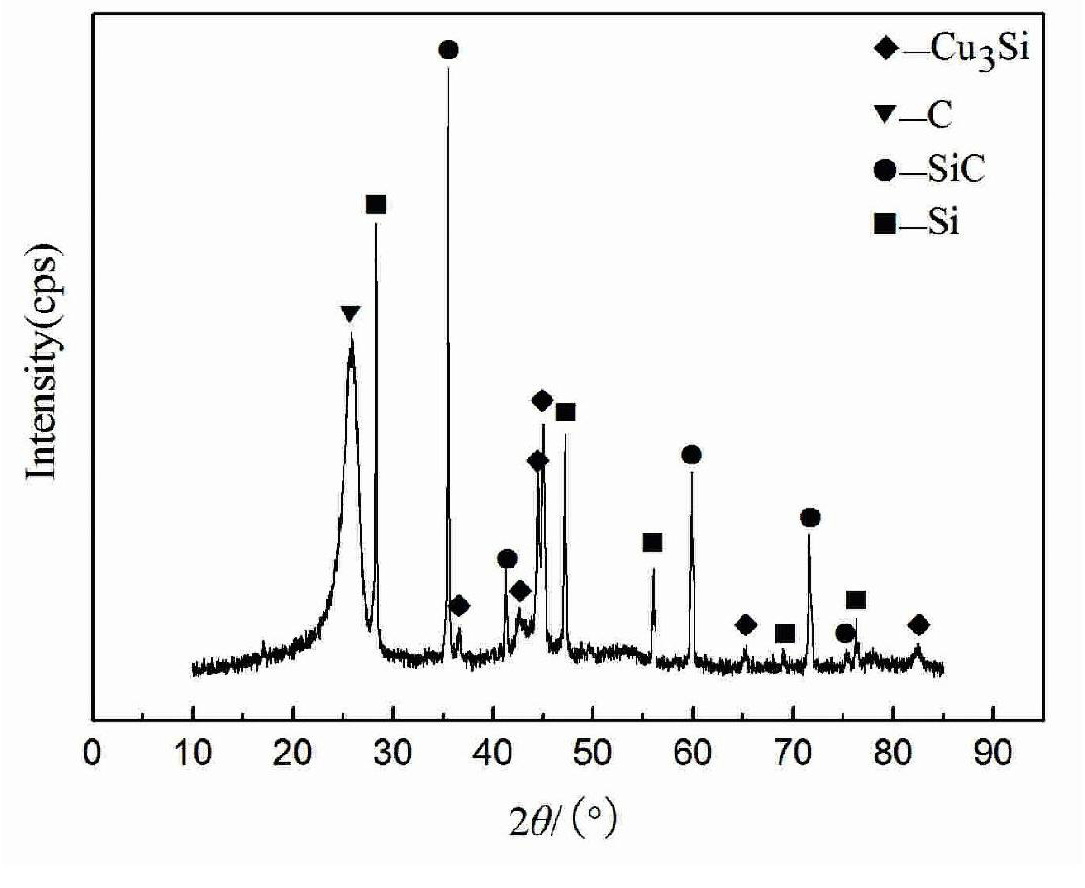

Embodiment 1

[0032] (1) The density is 0.56g / cm 3 The carbon fiber integral felt is a prefabricated body;

[0033]Under the protective atmosphere of argon, the preform is subjected to high-temperature heat treatment at 2300 ° C, and the holding time is 3 hours;

[0034] (2) Adopting propylene as carbon source gas, hydrogen as dilution gas, the volume ratio of propylene and hydrogen is 1: 2, adopting isothermal chemical vapor infiltration method to the preform processed through step (1) at 1100 ℃ of deposition heat Decomposition of charcoal, after 100 hours of deposition, the density is 1.24g / cm 3 Low-density C / C porous body material;

[0035] (3) After mixing Cu powder with a purity ≥ 99% and an average particle size of 0.01 to 0.1 mm and Si powder with a purity ≥ 99% and an average particle size of 0.05 to 0.075 mm according to a mass ratio of 2:3, take C / C The mixed powder of Si powder and Cu powder, which is 3 times the mass of the porous body, is evenly mixed and placed in a graphit...

Embodiment 2

[0039] (1) The density is 0.36g / cm 3 The carbon fiber integral felt is a prefabricated body;

[0040] Under the protective atmosphere of argon, the preform is subjected to high-temperature heat treatment at 1600 °C, and the holding time is 6 hours;

[0041] (2) Adopting natural gas as carbon source gas, hydrogen as dilution gas, the volume ratio of propylene and hydrogen is 1: 3, adopting thermal gradient chemical vapor infiltration method to deposit heat to the prefabricated body processed through step (1) under 1000 ℃ After decomposing carbon and depositing for 60 hours, the density is 0.84g / cm 3 The low-density C / C porous body material is impregnated with furan resin and carbonized to obtain a density of 1.35g / cm 3 The low-density C / C porous body material, the impregnation temperature is 100°C, and the carbonization temperature is 850°C;

[0042] (3) After mixing Cu powder with a purity of ≥99% and an average particle size of 0.01 to 0.1mm and Si powder with a purity of ...

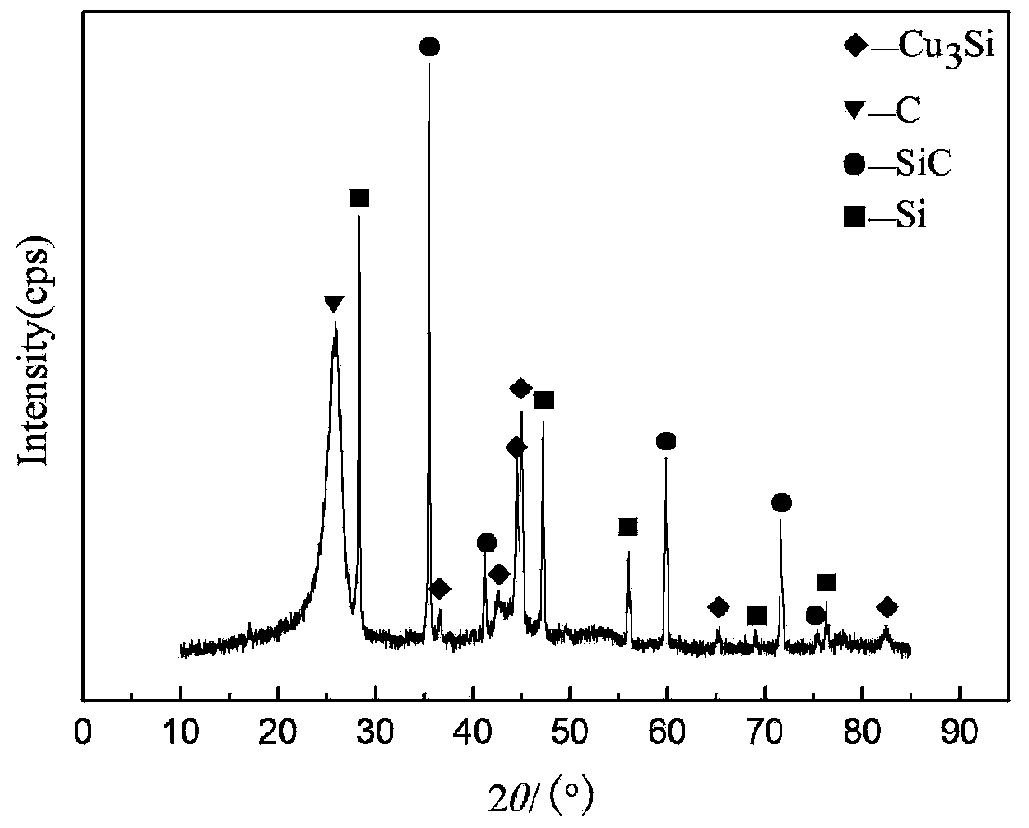

Embodiment 3

[0045] (1) The density is 0.14g / cm 3 The carbon fiber integral felt is a prefabricated body, and the prefabricated body is subjected to 1500? High temperature heat treatment, holding time: 10 hours;

[0046] (2) Impregnated with furan resin and carbonized to obtain a density of 1.20g / cm 3 The low-density C / C porous body material, the impregnation temperature is 85°C, and the carbonization temperature is 900°C;

[0047] (3) After mixing Cu powder with a purity of ≥99% and an average particle size of 0.01 to 0.1mm and Si powder with a purity of ≥99% and an average particle size of 0.05 to 0.075mm according to a mass ratio of 1:19, the C / C The mixed powder of Si powder and Cu powder which is 2 times of the mass of the porous body is uniformly mixed and placed in a graphite crucible and smoothed.

[0048] (4) Spread the low-density C / C porous body material obtained in step (2) on the graphite crucible powder obtained in step 3, and perform non-immersion melt infiltration in a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com