Novel stacked screw sludge dewatering machine and spiral shaft thereof

A sludge dewatering machine, screw shaft technology, applied in water/sludge/sewage treatment, sludge treatment, dewatering/drying/concentrated sludge treatment, etc. The effect of improving, improving the service life, expanding the processing capacity and adapting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

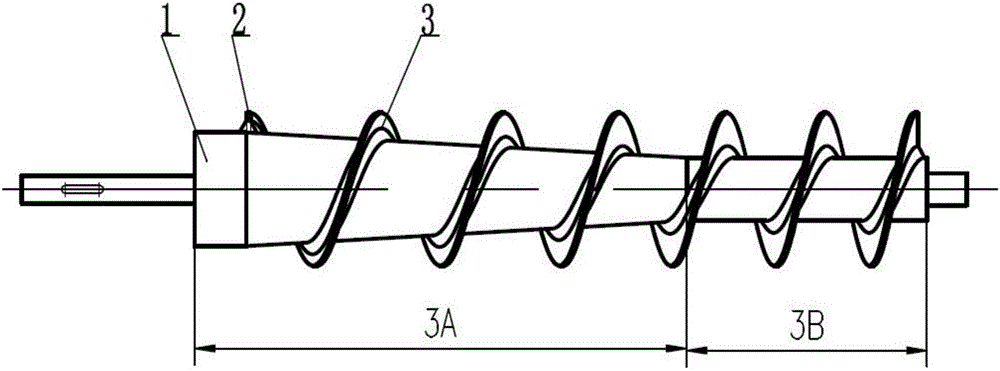

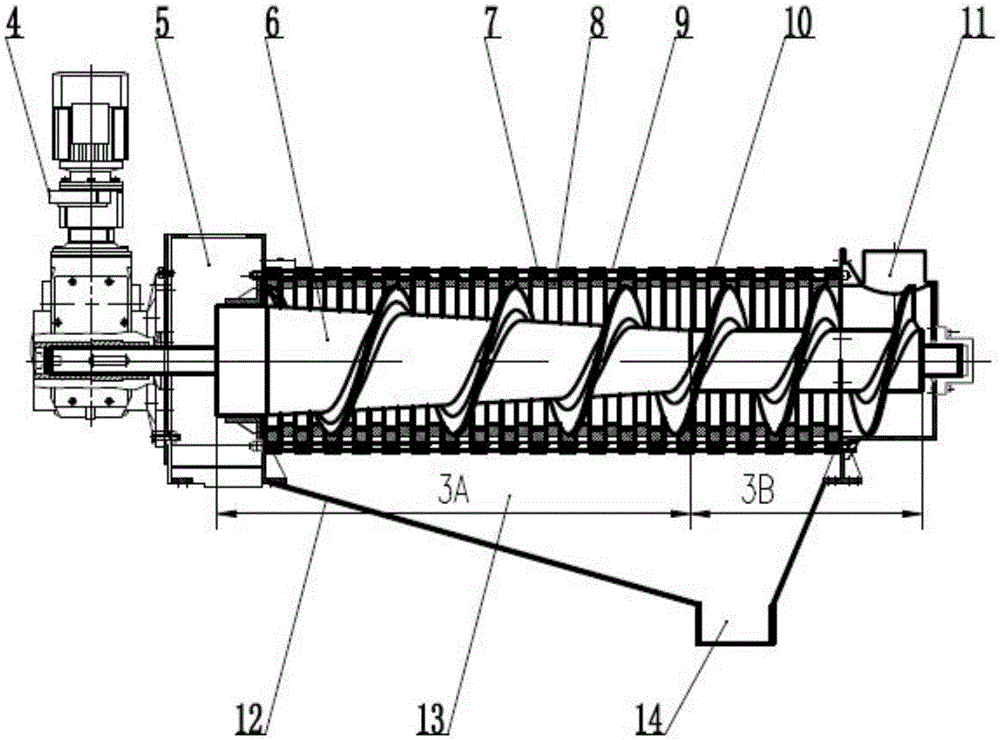

[0022] Such as figure 1 As shown, the screw shaft of a new screw-stacked sludge dewatering machine (referred to as the new screw shaft) adopts a variable-diameter and variable-pitch screw shaft. The mud inlet box gradually becomes smaller, and the lead angle gradually decreases from 16° to 22° to 6° to 14°; the pitch of the shaft body gradually increases along the direction of the mud box, and the pitch is more reasonable; and the screw shaft body is from From the position of 1 / 3 of the shaft length, its diameter gradually increases from the mud inlet box to the mud outlet box. On both sides of the bottom of the helical blade 3 of the novel helical shaft, there are anti-blocking plates 2 with an included angle of 20° to 45° with the center line of the shaft body 1, and the height is not less than 2 / 3 of the height of the helical blade. The function of the blocking plate is to reduce the frictional resistance of the right angle of the helical blade to the material during the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com