Cobalt catalyst and preparation method and application thereof

A cobalt catalyst and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve material loss, low activity, and reduced Al and O content, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

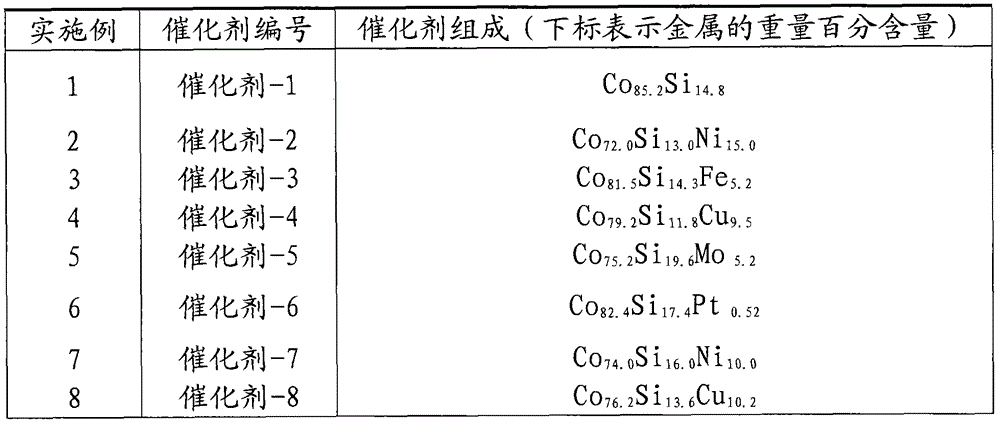

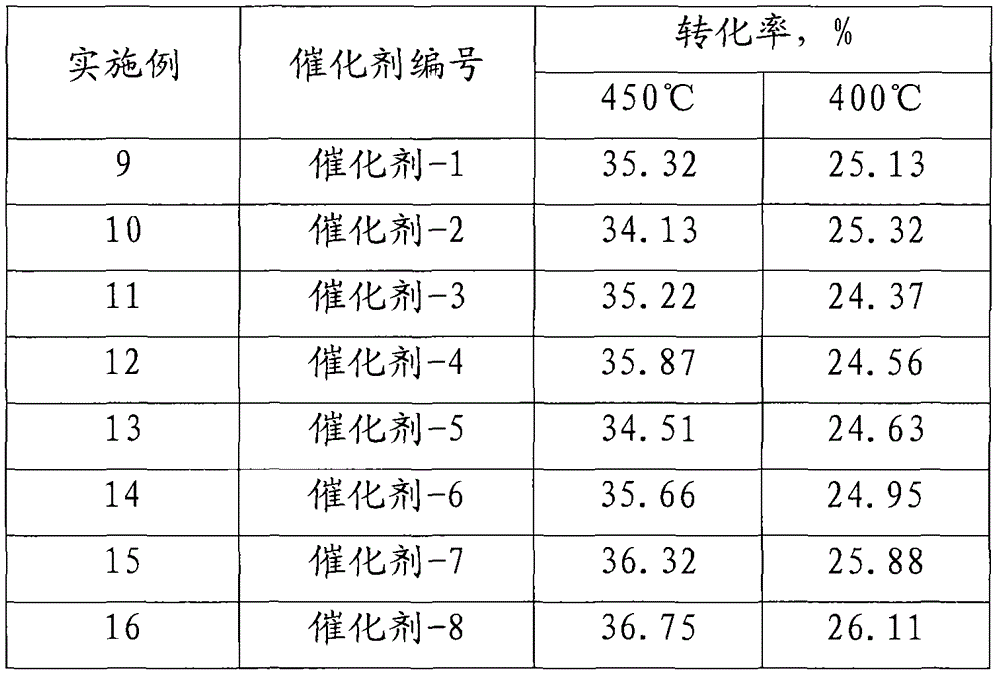

preparation example Construction

[0014] The preparation method of the cobalt catalyst provided by the invention is to heat cobalt, silicon, and transition metals to melt, cool the molten matter to solidify, and use an alkali-acid solution to extract the solidified alloy to extract part of the silicon. Get a catalyst. When the catalyst is used in the hydrogenation reaction of silicon tetrachloride, it has higher activity and selectivity than conventional catalysts, and has good stability.

[0015] More specifically, the preparation method will be composed of cobalt, silicon, and or not and at least one transition metal selected from the group IB, IIB, IIIB, IVB, VIB, VIIB or VIII of the periodic table of the elements. The cooling rate greater than 1000°C / S solidifies quickly, and the solidified product is added to the alkali solution heated to the extraction temperature of 10-100°C under stirring, so that the silicon in the alloy can fully react with the alkali, and then decant the liquid and solid samples Af...

Embodiment 1

[0024]Add 1.5kg of cobalt and 1.5kg of silicon into a graphite crucible, heat it in a high-frequency furnace until it melts, and then spray the melt from the nozzle of the crucible onto a copper roller with a rotation speed of 600 to 1000 rpm. The cooling water is passed through the roller, the alloy liquid is rapidly cooled at a cooling rate greater than 1000°C / s, and then thrown into the water along the tangent line of the copper roller to form scale-like strips, which are ground to a particle diameter of less than 500 microns to obtain master alloy. Slowly add 50 g of the master alloy into a three-neck flask filled with 500 g of 20 wt % sodium hydroxide aqueous solution, control its temperature to 60° C. and keep stirring at constant temperature for 1 hour. After stopping heating and stirring, decant the liquid; add distilled water to wash until the pH value is less than 10; then add it to 100 grams of 20 wt% nitric acid solution, control the temperature at 80° C. and keep ...

Embodiment 2

[0026] Add 1.5kg of cobalt, 1.0kg of silicon and 0.5kg of nickel into a graphite crucible, heat it in a high-frequency furnace until it melts, and then spray the melt from the nozzle of the crucible onto a copper roller with a rotational speed of 900 rpm , the cooling water is passed through the copper roller, and the alloy liquid is rapidly cooled at a cooling rate greater than 1000°C / s, and then thrown into the water along the tangent of the copper roller to form scale-like strips, which are ground to a particle diameter of less than 500 microns , to obtain the master alloy. Slowly add 50 g of the master alloy into a three-neck flask filled with 500 g of 20 wt % sodium hydroxide aqueous solution, control its temperature to 60° C. and keep stirring at constant temperature for 1 hour. After stopping heating and stirring, decant the liquid; add distilled water to wash until the pH value is less than 10; then add it to 100 grams of 20 wt% nitric acid solution, control the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com