Oxide ceramic/alkali-earth metal sulphate/silver composite material and preparation method thereof

A technology of oxide ceramics and alkaline earth metals, which is applied in the field of oxide ceramic matrix composite materials and their preparation, can solve the problems of high sintering temperature and poor friction and wear performance in the preparation process, and achieves low friction, good friction and wear performance, and tight bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

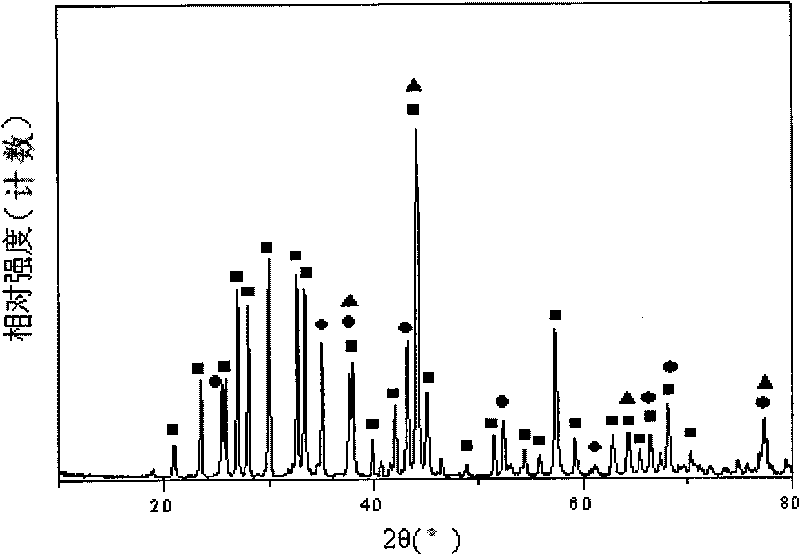

[0011] Specific embodiment one: In this embodiment, a kind of oxide ceramics / alkaline earth metal sulfate / silver composite material is composed of 20%~50% oxide ceramic phase, 30%~60% alkaline earth metal sulfate phase and 5%~50% by volume percentage. 25% silver phase composition.

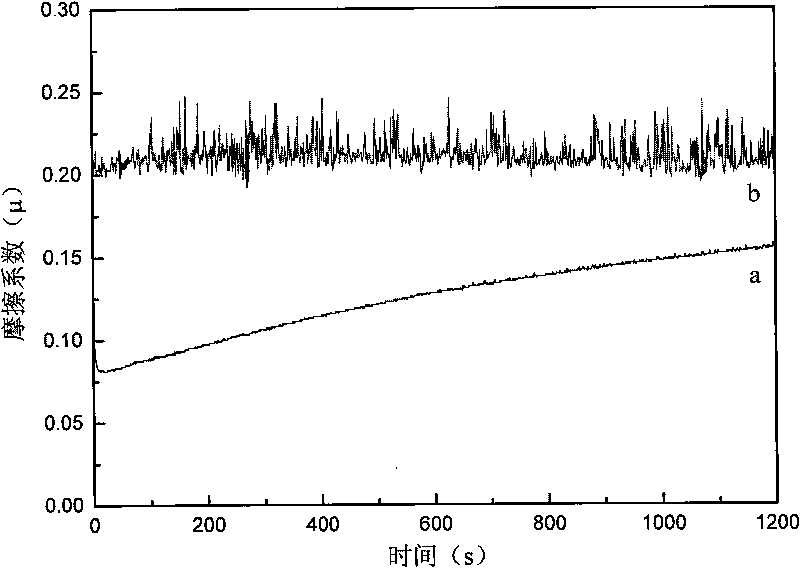

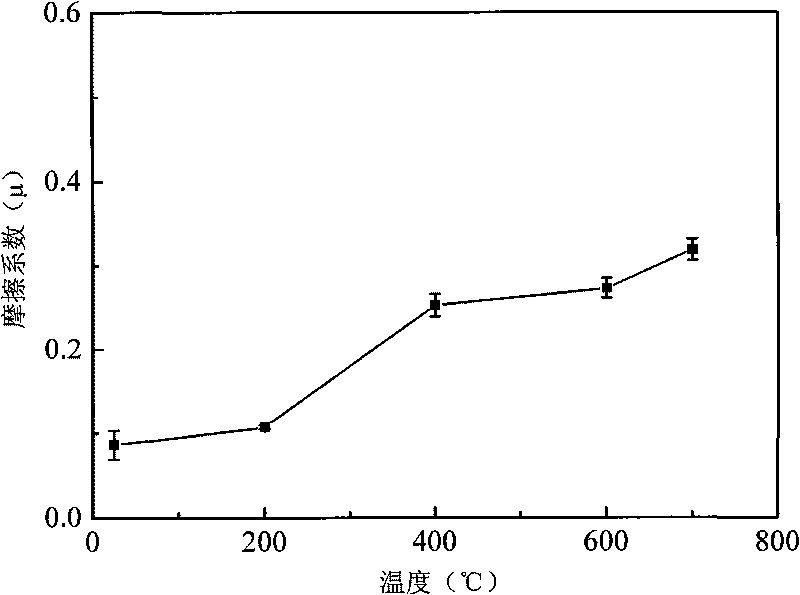

[0012] In this embodiment, the oxide ceramic / alkaline earth metal sulfate / silver composite material has a friction coefficient of 0.05-0.15 at room temperature, and a friction coefficient of 0.18-0.25 at a high temperature of 760°C, both of which are lower than the friction of existing oxide ceramic ceramic materials. coefficient, especially at high temperatures, the reduction of friction coefficient is more obvious; the wear rate of oxide ceramics / alkaline earth metal sulfate / silver composites is less than 10 at room temperature and at a high temperature of 760 °C -6 mm 3 / N·m order of magnitude. In this embodiment, the oxide ceramic / alkaline earth metal sulfate / silver composite material also ex...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the oxide ceramics / alkaline earth metal sulfate / silver composite material is composed of 30% to 40% oxide ceramic phase and 40% to 50% alkaline earth metal sulfuric acid by volume percentage. Salt phase and 10% to 20% silver phase composition. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the oxide ceramics / alkaline earth metal sulfate / silver composite material is composed of 40% oxide ceramic phase, 50% alkaline earth metal sulfate phase and 10% silver by volume percentage phase composition. Other parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com