Formula of rubber-free type winding form clutch plate and technique thereof

A clutch face, winding technology, applied in the field of automotive friction materials, can solve problems such as slipping, high hardness of the clutch face, no elasticity, and easy vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

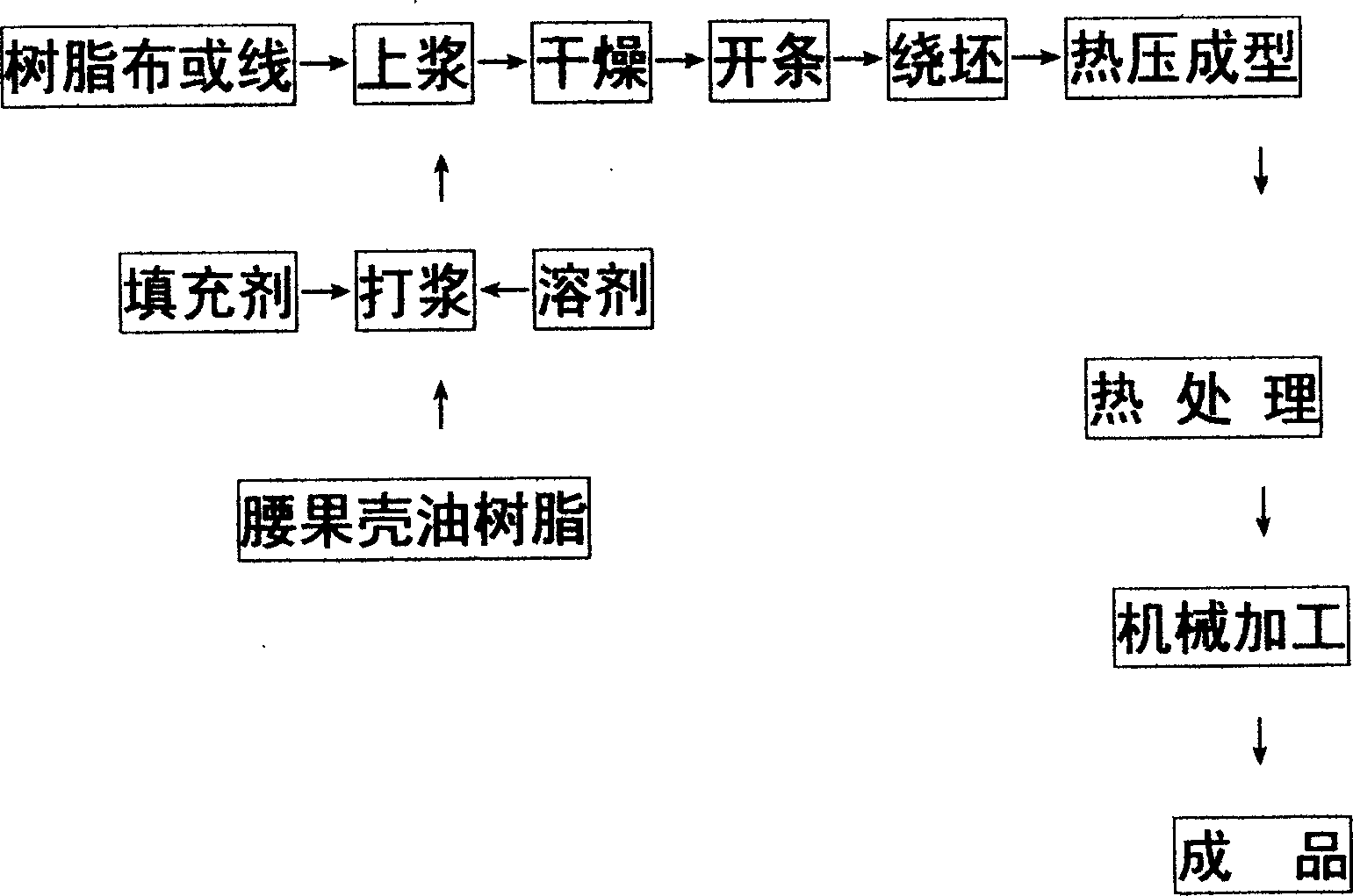

Method used

Image

Examples

Embodiment Construction

[0011] The following takes the production of 100 kilograms of rubber-free wound clutch facings as an example to further describe the present invention:

[0012] The raw material structure is: (calculated by weight)

[0013] 1. Fiber cloth 35

[0014] 2. The formula of cashew nut shell oil resin slurry is as follows:

[0015] Cashew nut shell oil resin 18

[0017] Wollastonite powder 10

[0018] Kaolin 10

[0020] Friction powder 3

[0021] Graphite 3

[0022] Carbon black 1

[0023] Xylene 17

[0024] The production is carried out according to the weighing of the formula, and the production process is as follows: (The relevant raw materials evaporate 19Kg during the production process)

[0025] 1. Beating: Put the weighed cashew nut shell resin, barium sulfate, wollastonite powder, kaolin, calcium carbonate, friction powder, graphite, carbon black, and xylene into the beater one after another, and beat them into uniform cashe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com