Cobalt catalyst, preparation method and application thereof

A technology of cobalt catalysts and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problem of hindering the industrialization of Fischer-Tropsch synthesis process problems such as small particles, to achieve good catalyst particle wear performance, high activity and selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

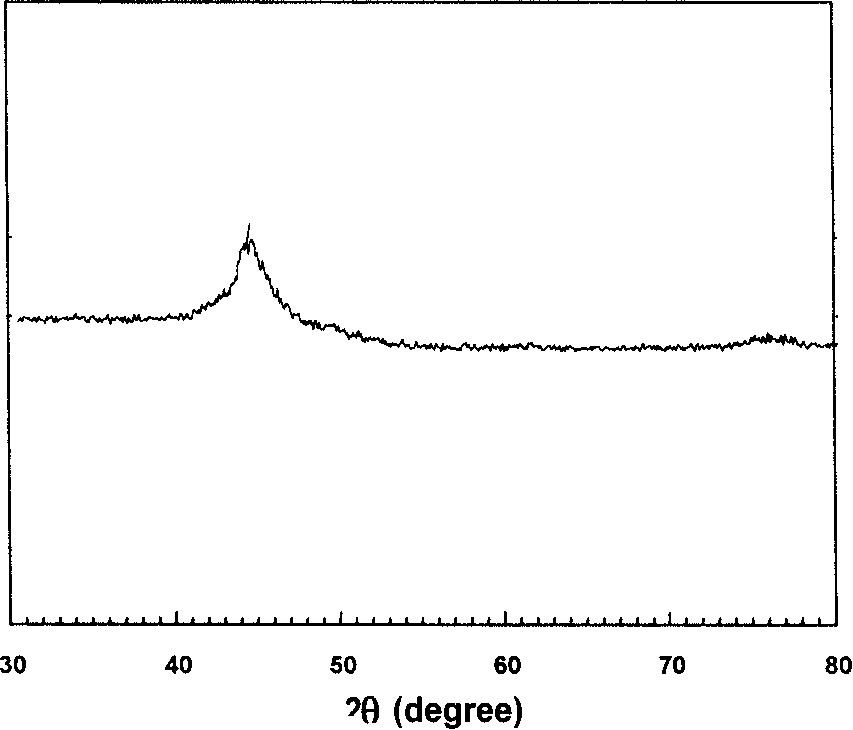

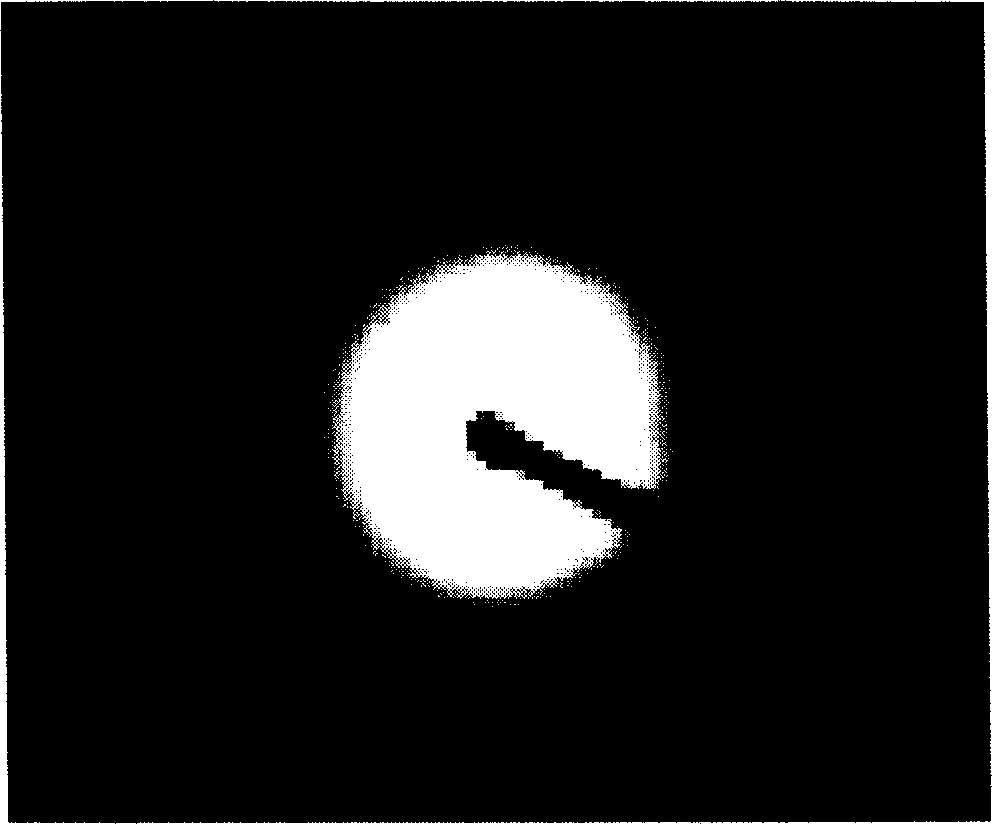

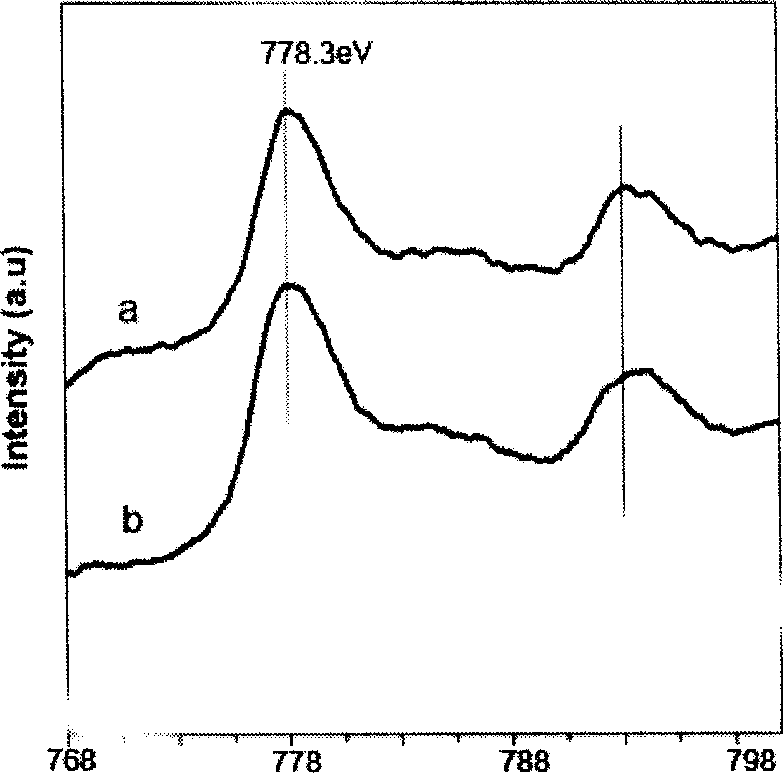

[0041] Add 1.5kg of cobalt and 1.5kg of aluminum into the graphite crucible, heat it in a high-frequency furnace to above 1300°C and melt it to alloy it, and then spray the alloy liquid from the nozzle of the crucible to a speed of 1000 rpm On the copper roller, the cooling water is passed through the copper roller, and the alloy liquid is 10 6 After rapid cooling at the cooling rate of ℃ / s, it is thrown out along the tangent line of the copper roll to form scale-like strips. The scale-like strips are ground to a particle diameter of less than 70 microns to obtain a master alloy. Slowly add 50 g of the master alloy into a three-neck flask filled with 500 g of 20% aqueous sodium hydroxide solution, control its temperature to 80° C. and keep stirring at constant temperature for 1 hour. After stopping heating and stirring, decant the liquid and wash with distilled water at 100°C until the pH value is 7. The prepared catalyst is numbered Catalyst-1.

[0042] The composition of C...

Embodiment 2

[0046] Add 1.0kg of cobalt and 2.0kg of aluminum into the graphite crucible, heat it in a high-frequency furnace to above 1300°C and melt it to alloy it, and then the alloy liquid is sprayed from the nozzle of the crucible to a speed of 900 rpm On the copper roller, the cooling water is passed through the copper roller, and the alloy liquid is 10 5 After rapid cooling at the cooling rate of ℃ / s, it is thrown out along the tangent line of the copper roll to form scale-like strips. The scale-like strips are ground to a particle diameter of less than 70 microns to obtain a master alloy. Slowly add 50 g of the master alloy into a three-neck flask filled with 500 g of 20% aqueous sodium hydroxide solution, control its temperature to 80° C. and keep stirring at constant temperature for 1 hour. After stopping heating and stirring, decant the liquid and wash with distilled water at 80°C until the pH value is 7. The prepared catalyst is numbered Catalyst-2.

[0047] The composition o...

Embodiment 3

[0051] Add 480g of cobalt, 480g of aluminum, and 20g of copper into the graphite crucible, heat it in a high-frequency furnace to above 1600°C to melt, and make it alloyed, and then the alloy liquid is sprayed from the nozzle of the crucible to a speed of 670 rpm On the divided copper roll, cooling water is passed through the copper roll, and the alloy liquid is 10 4 The cooling rate of ℃ / s is rapidly cooled and thrown out along the tangent line of the copper roller to form scaly strips, which are ground to a particle diameter of less than 70 microns. Slowly add 50 g of the master alloy into a three-neck flask filled with 500 g of 20% aqueous sodium hydroxide solution, control its temperature to 70° C. and keep stirring at constant temperature for 1 hour. After stopping heating and stirring, decant the liquid and wash with distilled water at 80°C until the pH value is 7. The prepared catalyst is numbered Catalyst-3.

[0052] The composition of Catalyst-3 is shown in Table 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com