Method and equipment for depositing ultrahard and ultrathick DLC film layers on aircraft blade based on ion beam technology

A DLC film and aircraft blade technology, which is applied in the field of surface modification of ray beam materials, can solve the problem of easy erosion of friction coefficient aero-engines, etc., and achieve the effect of enhancing peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

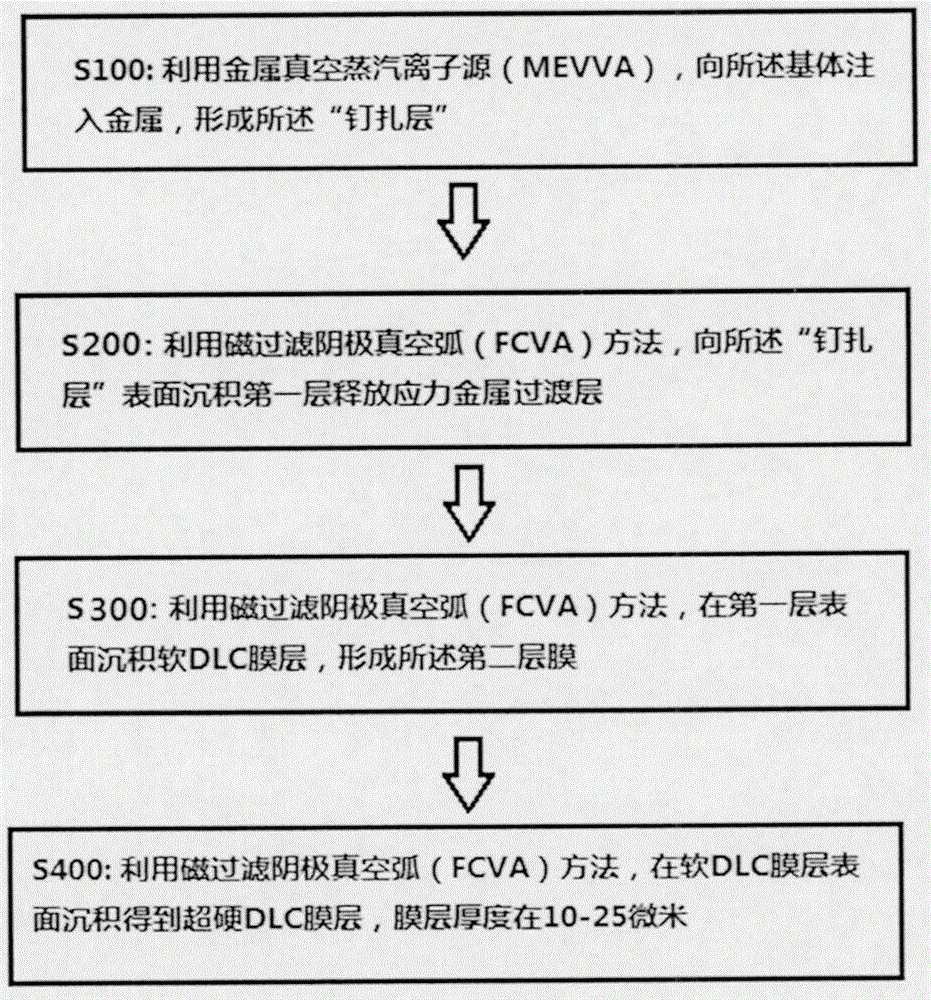

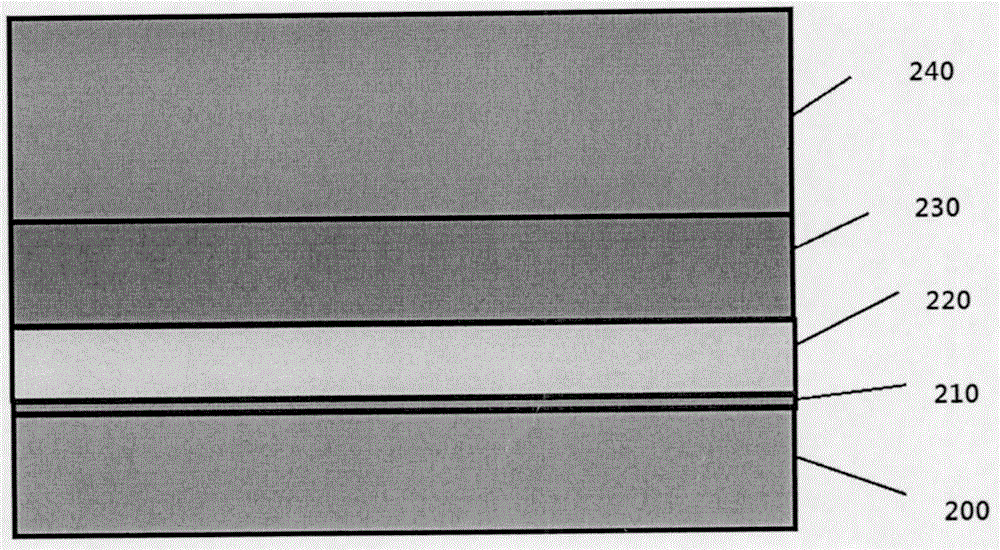

[0055] It should be noted that, in this embodiment, a DLC film is prepared on the base layer, and the selected base layer is the blade base material TC4, referring to figure 1 , which shows the DLC film preparation method of this embodiment, the preparation method includes the following steps:

[0056] S100: Using a metal vapor vacuum arc (MEVVA) ion source, injecting a first metal element into the base layer to form a metal "pinned layer".

[0057] Among them, this step is metal ion implantation to form a "pinning layer". Implantation of high-energy metal ions into the substrate can form a mixed layer of metal and substrate material to improve the bonding force between the subsequent film layer on the surface and the substrate.

Embodiment approach

[0059] The injection voltage of the first metal element is 4-15kV, the beam current intensity is 1-15mA (including the end value), and the injection dose is 1×10 15 ~1×10 17 / cm 2 (end value included), implantation depth is 70-120nm (end value included).

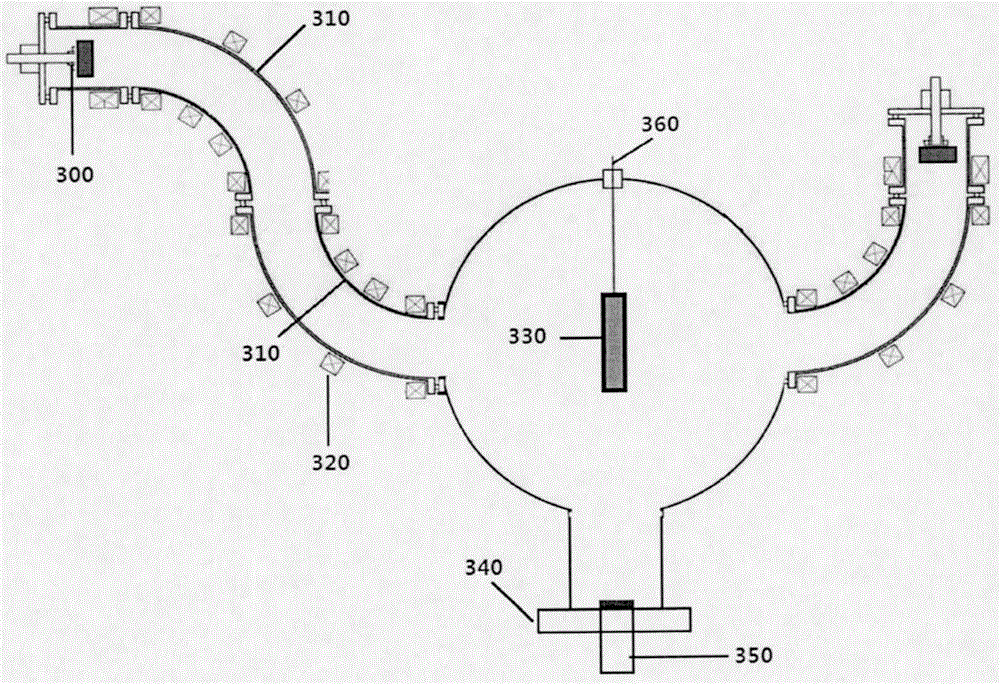

[0060] S200: Using a magnetic filter cathodic vacuum arc (FCVA) system, on the surface of the substrate "pinning layer", 90-degree magnetic filter deposition is used to obtain the first layer of metal internal stress release layer.

[0061] In this step, optionally, the first metal film layer may be a Ti film layer or a Ni film layer, and the thickness is 10-500 nm.

[0062] S300: Using the magnetic filter cathodic vacuum arc (FCVA) system, on the surface of the first metal internal stress release layer, 180-degree magnetic filter deposition to obtain the second layer of soft DLC film.

[0063] In this step, optionally, the cathode for arc formation to form plasma is carbon, and the thickness of the soft DLC is 10-1000 nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com