Compact cadmium sulfide thin film preparation device and method

A cadmium sulfide, thin film technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of inability to remove large particles and dirt, large magnetic agitation, poor sample results, etc., to reduce The effect of large particles and other impurities, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

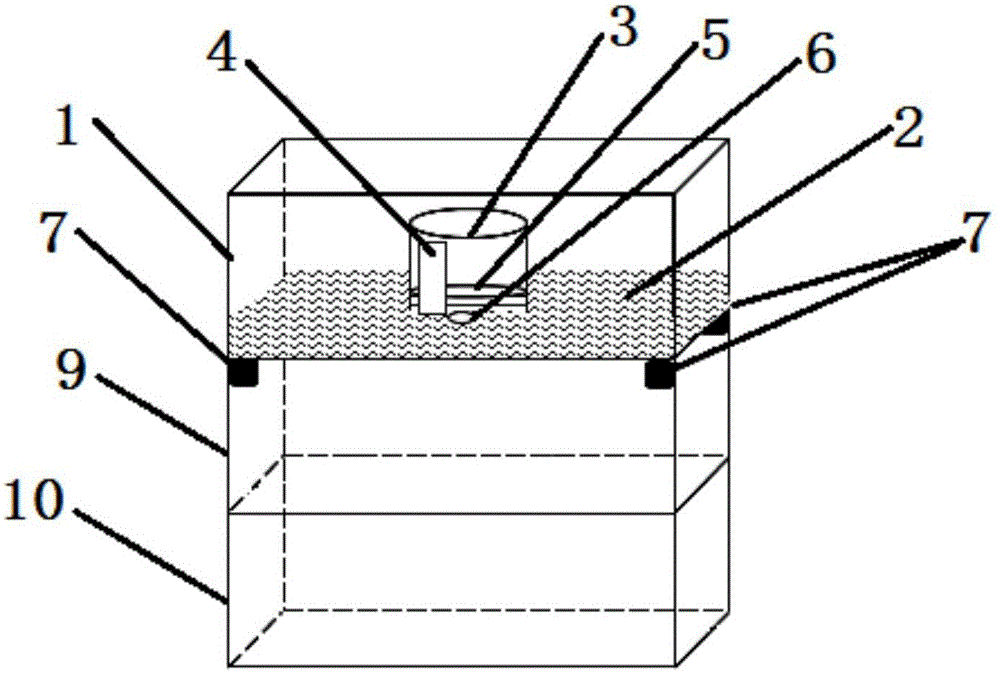

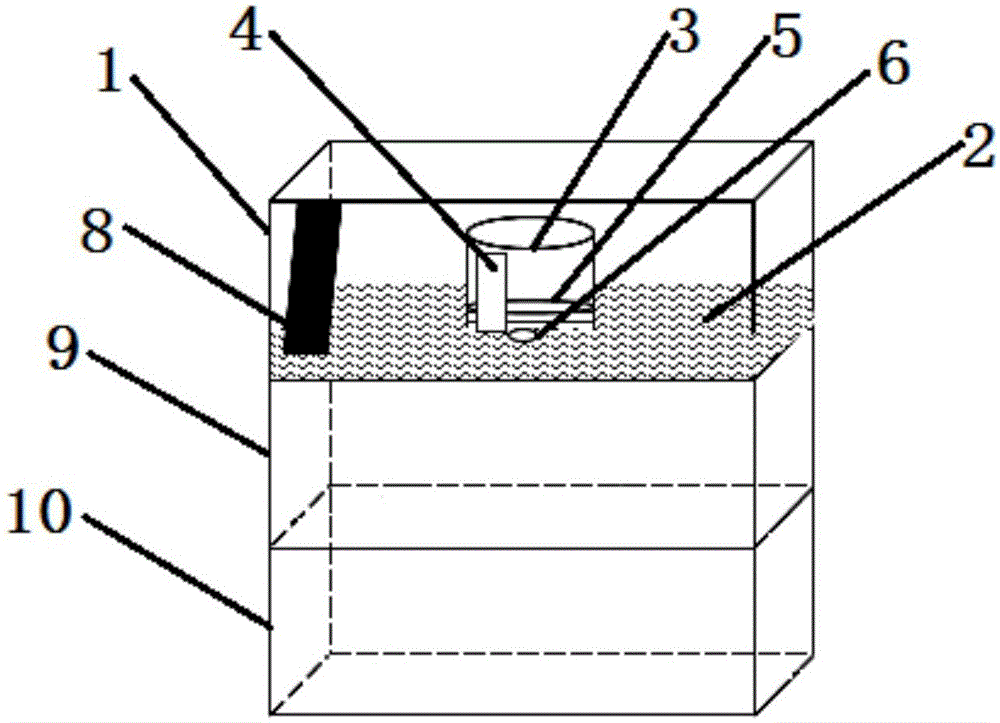

[0032] Embodiment 1: refer to figure 1 Shown is a device for preparing a dense cadmium sulfide film. The device has a length of 10-20 cm, a width of 10-20 cm, and a height of 30-50 cm. The main materials used are aluminum and stainless acid-resistant steel.

[0033] The device that the present invention prepares compact cadmium sulfide thin film comprises sequentially arranged from top to bottom:

[0034] Water tank 1, at least one 500mL beaker can be put into the water tank 1, and water 2 and reaction vessel 3 are housed inside the water tank 1, and at least one substrate 4 and reaction solution placed horizontally or vertically in the reaction vessel 3 are housed in the reaction vessel 3 5 and magnet 6, and four ultrasonic vibrators 7 are set at the bottom of the water tank 1 at the same time, and the ultrasonic vibrators 7 are placed in a dry and clean environment. At the same time, the ultrasonic vibrators 7 are detachable, and different frequencies can be replaced. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com