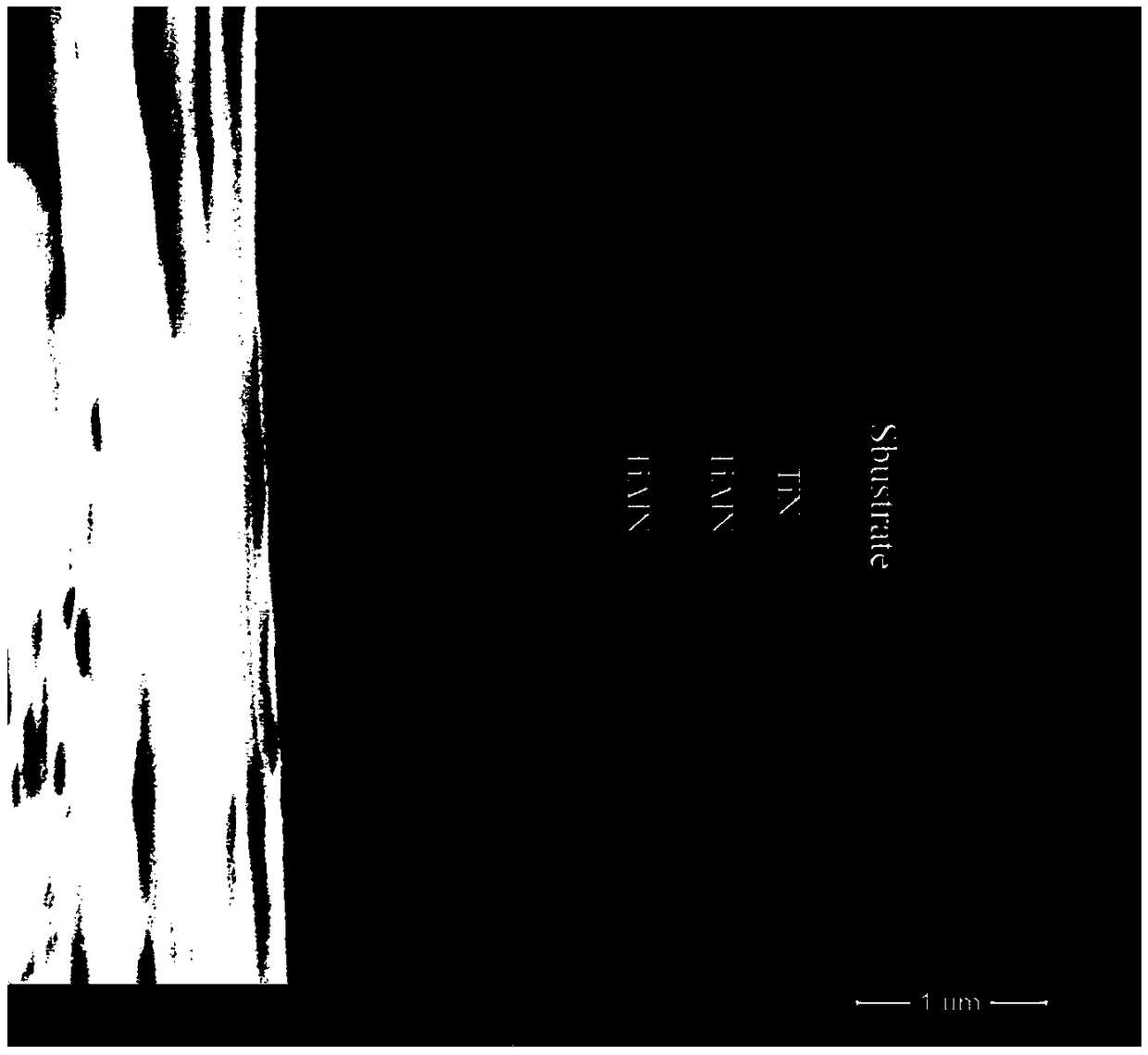

TiAlN/W2N multi-layer coating with high hardness and high corrosion resistance and preparation method thereof

A multi-layer coating and high hardness technology, which is applied in the coating, metal material coating process, superimposed layer plating, etc., can solve the problems of harsh service environment and the performance of TiN hard coating can not meet the industrial needs, etc. Achieve the effect of simple operation, beneficial to industrial application, and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The TiAlN / W of this embodiment 2 The specific preparation method of N multi-layer coating is as follows:

[0042] Clean the ground and polished stainless steel substrate with analytical pure absolute ethanol and acetone in ultrasonic waves, check whether the surface of the substrate is clean after drying, and install it on the turntable of the vacuum chamber after confirming that the surface of the substrate is free of pollution. Close the door of the vacuum chamber for vacuuming. Air pressure reaches 1.0×10 -3 After Pa, pass argon gas into the vacuum chamber to maintain the pressure at 0.5 Pa, the flow rate of argon gas is 70 sccm, and at the same time adjust the substrate DC bias voltage to 180V, the pulse bias voltage to 800V, and the duty cycle to 80%, and turn on the Hall ion source , Glow cleaning the substrate for 30min. After the glow cleaning, the Hall ion source was turned off, nitrogen gas was introduced into the vacuum chamber, the air pressure was mainta...

Embodiment 2

[0045] The TiAlN / W of this embodiment 2 The specific preparation method of N multi-layer coating is as follows:

[0046] Clean the ground and polished cemented carbide substrate with analytical pure absolute ethanol and acetone in ultrasonic waves, check whether the surface of the substrate is clean after drying, and install it on the turntable in the vacuum chamber after confirming that the surface of the substrate is free of pollution , close the door of the vacuum chamber, and carry out vacuuming operation. Air pressure reaches 1.0×10 -3 After Pa, pass argon gas into the vacuum chamber to maintain the pressure at 0.5 Pa, the flow rate of argon gas is 70 sccm, and at the same time adjust the substrate DC bias voltage to 180V, the pulse bias voltage to 800V, and the duty cycle to 80%, and turn on the Hall ion source , Glow cleaning the substrate for 30min. After the glow cleaning, the Hall ion source was turned off, nitrogen gas was introduced into the vacuum chamber, the ...

Embodiment 3

[0049] The TiAlN / W of this embodiment 2 The specific preparation method of N multi-layer coating is as follows:

[0050] Clean the ground and polished stainless steel substrate with analytical pure absolute ethanol and acetone in ultrasonic waves, check whether the surface of the substrate is clean after drying, and install it on the turntable of the vacuum chamber after confirming that the surface of the substrate is free of pollution. Close the door of the vacuum chamber for vacuuming. Air pressure reaches 1.0×10 -3 After Pa, pass argon gas into the vacuum chamber to maintain the pressure at 0.5 Pa, the flow rate of argon gas is 70 sccm, and at the same time adjust the substrate DC bias voltage to 180V, the pulse bias voltage to 800V, and the duty cycle to 80%, and turn on the Hall ion source , Glow cleaning the substrate for 30min. After the glow cleaning, the Hall ion source was turned off, nitrogen gas was introduced into the vacuum chamber, the air pressure was mainta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com