Liquid thermosetting resin composition and method for manufacturing printed circuit board using the same

A technology of resin composition and printed circuit board, which is applied in the direction of printed circuit components, etc., can solve problems such as insufficient glue filling, CTE mismatch, and easy cracks, etc., achieve good wet metal performance, improve plug hole dissatisfaction, and improve The effect of thermal reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

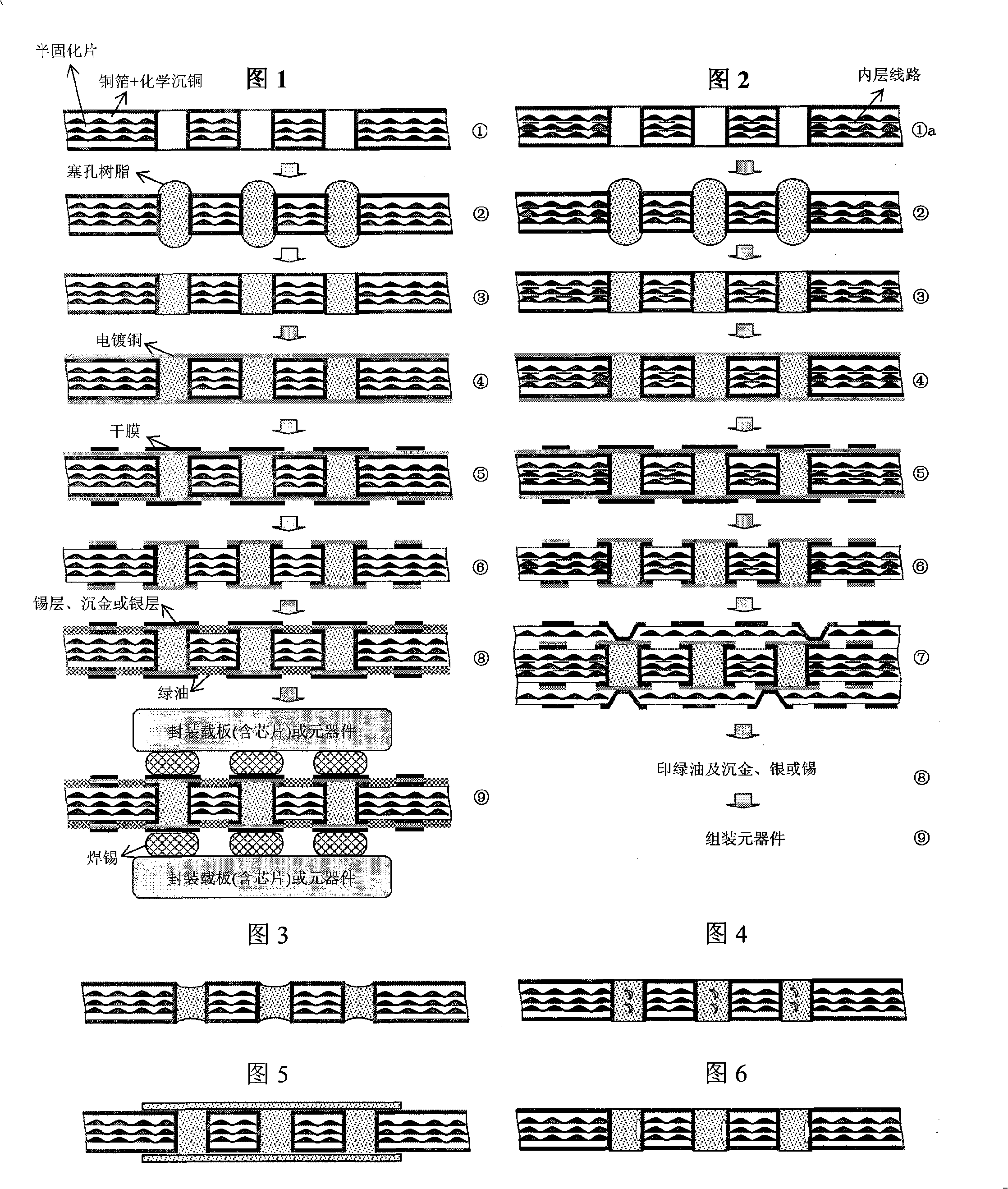

Method used

Image

Examples

Embodiment 6

[0064] The difference between Example 6 and Example 1 is that the bisphenol F-type epoxy resin is partially replaced by the novolac epoxy resin of the multifunctional group, and the 4,4-DDS curing agent is not used at the same time to increase the Tg and reduce the cost. The purpose is to reduce the cost and CTE of low temperature to high temperature (for example, 50-260°C) on the basis of ensuring good fluidity of the resin, and prevent the occurrence of resin cracks in the holes. The function of all the other components is identical with embodiment 1.

[0065] Table 2 shows the characteristics of the liquid thermosetting resin compositions of the above embodiments and comparative examples and the test results of their application in making printed circuit boards. Viscosity is tested by Brookfield Viscometer (Brookfield viscometer), Tg (glass transition temperature) is tested by DSC (differential scanning calorimetry), CTE (thermal expansion coefficient) is tested by TMA (the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com