Large velocity ratio marine gearbox

A gear box, high speed ratio technology, applied in the direction of gear transmission, gear lubrication/cooling, mechanical gear transmission, etc., can solve the problems of difficult assembly and disassembly, poor quality of gear meshing, large single-stage reduction ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

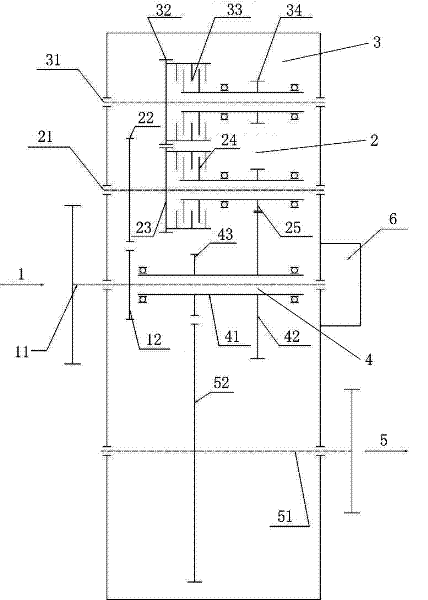

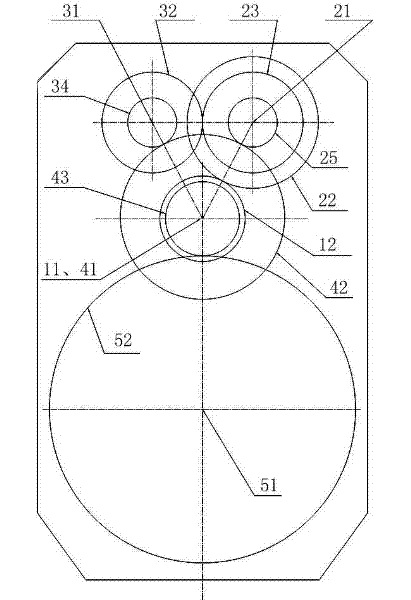

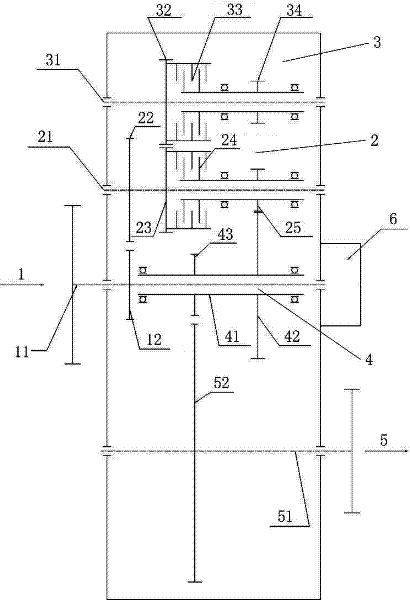

[0008] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the present invention is mainly composed of an input part 1, a forward axle part 2, a reverse axle part 3, an intermediate shaft part 4, an output part 5 and a box body part; Gear 12, the input gear 12 meshes with the shunting drive gear 22 that is shrunk on the shunting shaft 21 of the shunting shaft part 2, and the shunning clutch 24 with the shunning clutch housing gear 23 is installed on the shunting shaft 21 of the shunting shaft part 2 The reversing shaft part 3 includes a reversing shaft 31 and a reversing clutch 33 with a reversing clutch housing gear 32; The driving gear 25 and the driving gear 34 in reverse, and the driving gear 25 in driving and the driving gear 34 in reverse are respectively engaged with the intermediate transmission gear 42 fixedly connected on the intermediate shaft 41 of the intermediate shaft part 4; on the intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com