Gear oil composition and preparation method thereof

A technology of composition and gear oil, which is applied in the field of lubricating oil, can solve the problems of high solubility of base oil, difficulty in preparing uniform and transparent liquid, and complicated preparation process of friction reducing agent, so as to reduce energy consumption, viscosity and temperature Excellent performance, noise reduction and body temperature reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Specifically, the alkoxy phosphate antiwear agent can be a commercially available product, or it can be prepared by a conventional preparation method. For example, the preparation method of the alkoxy phosphate antiwear agent The method includes: reacting low carbon alcohol with phosphorus oxychloride to obtain alkyl phosphoric acid, and reacting the alkyl phosphoric acid with amine to obtain alkoxy phosphate antiwear agent.

[0047] According to the gear oil composition of the present invention, based on the total weight of the gear oil composition as 100%, the addition of fatty acid is 0.1-3%, preferably 0.3-2%; when the addition of fatty acid is less than 0.1% , cannot promote the sufficient dissolving of hydrophilic fumed silicon dioxide, and when the addition of fatty acid is greater than 3%, its effect of promoting dispersion no longer continues to increase, and the utilization rate of fatty acid of the present invention declines.

[0048] Specifically, the fatty ...

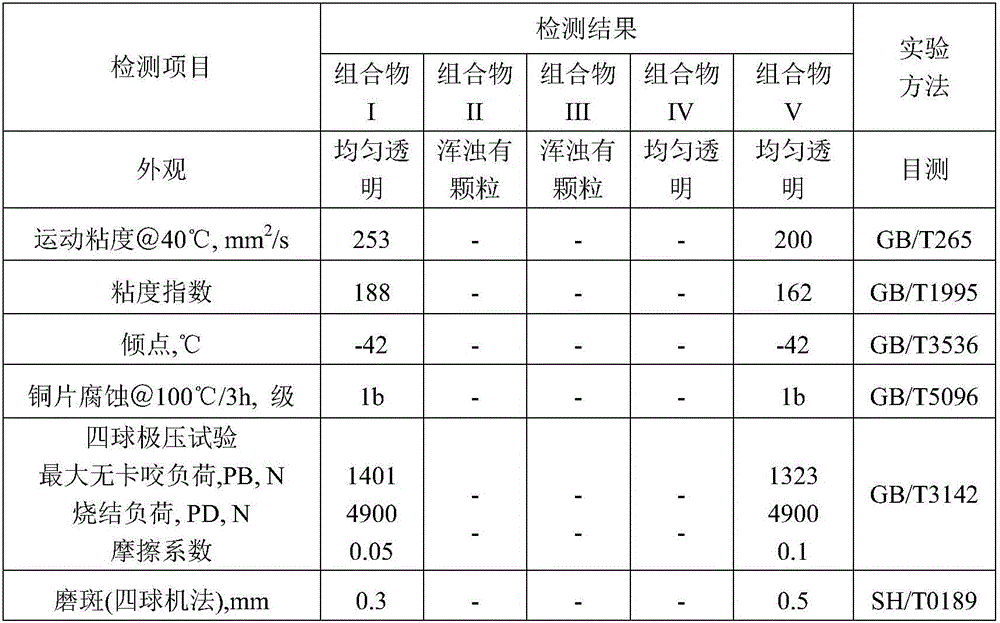

Embodiment 1

[0074] Add 1 part by weight of dodecyltrimethoxysilane (manufacturer: Nanjing Quanxi Chemical Co., Ltd., brand QX-1213, the same below) to 1 part by weight of hydrophilic fumed silica (manufacturer : Evonik Degussa company, trade mark: AEROSIL 300, hereinafter the same) in the heating vessel, be warming up to 80 ℃, fully stir 20min; With the pentaerythritol ester of 60 weight parts (manufacturer: Croda Chemical company, trade mark: Priolube3987, hereinafter the same) and 33.9 parts by weight of polyalphaolefin synthetic oil (manufacturer: Exxonmobil company, trade mark: Synbase Polyolefin40) joins in the reactor, maintains still temperature at 80 ℃, adds the stearic acid of 1 weight part, stirs 7min to uniform transparency; Add the mixture of dodecyltrimethoxysilane and hydrophilic fumed silica in the heating container into the stainless steel mixing kettle, stir for 10 minutes, stop heating, and use cooling water to lower the temperature of the kettle to 50 ° C, and then succe...

Embodiment 2

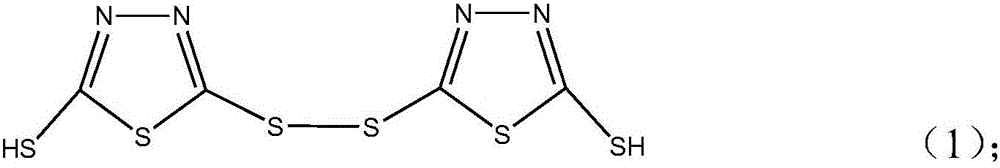

[0091] Add 0.8 parts by weight of dodecyltrimethoxysilane into a heating container containing 0.5 parts by weight of hydrophilic fumed silica, raise the temperature to 90°C, and stir thoroughly for 10 minutes; add 84.3 parts by weight of mineral oil 150BS (Manufacturer: Sinopec Maoming Petrochemical Company, brand: 150BS) and 10 parts by weight of pentaerythritol ester were added to the reaction kettle, and the temperature of the reaction kettle was maintained at 90 ° C. Added 1 part by weight of dodecyl hydroxystearic acid and stirred for 10 minutes until uniform Transparent; then add the mixture of dodecyltrimethoxysilane and hydrophilic fumed silica in the heating container into the stainless steel mixing kettle, stir for 30 minutes, stop heating, and use cooling water to lower the temperature of the kettle to 50°C. Then sequentially add 0.8 parts by weight of thiadiazole disulfide dimer, 1.5 parts by weight of alkoxy phosphate, 1 part by weight of octylbutyl diphenylamine, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com