A method for remelting and reducing modification of massive steel slag

A treatment method, steel slag technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of less total amount, waste of iron element, low early strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

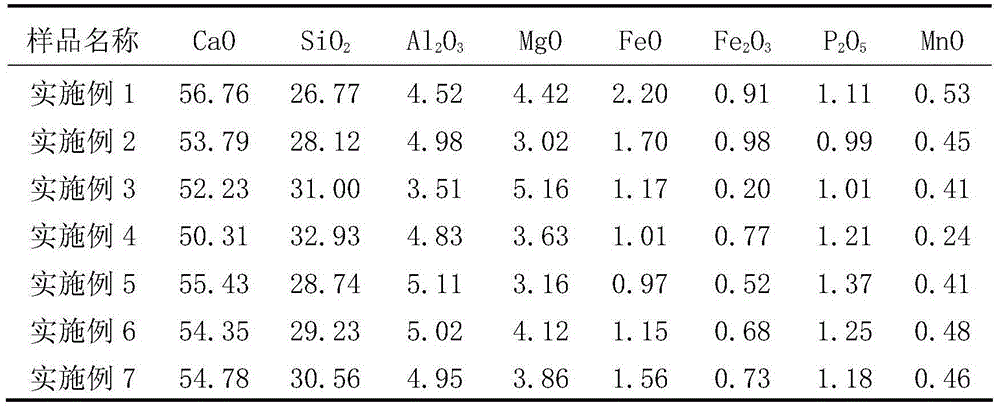

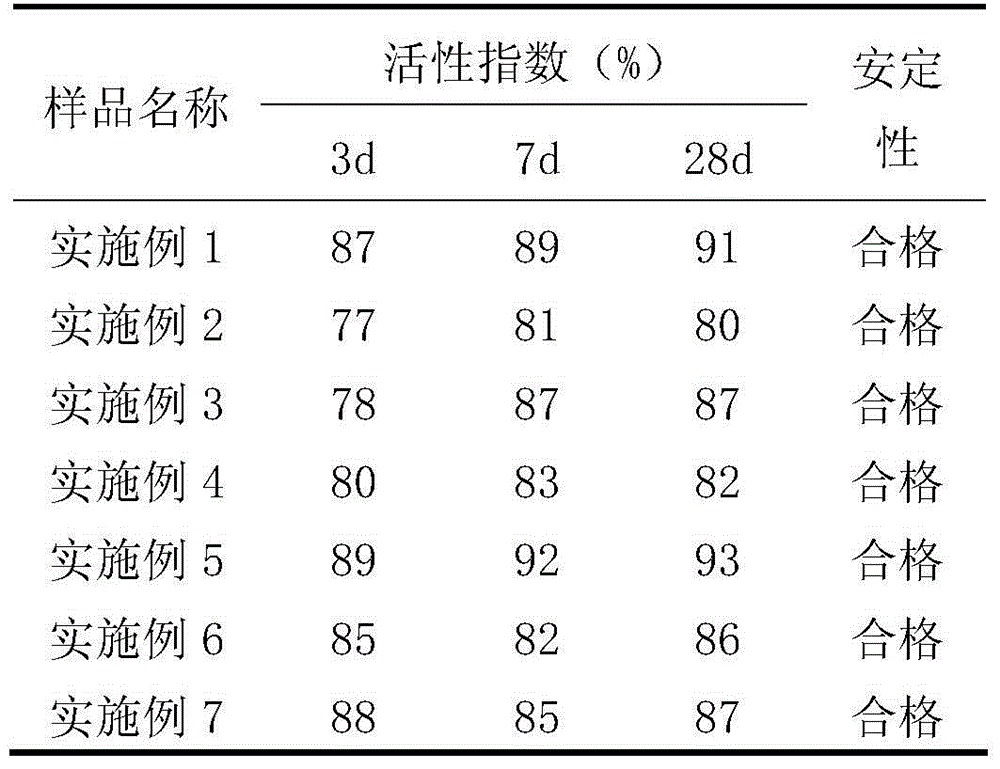

Embodiment 1

[0019] Example 1, take 1000kg of massive steel slag, take coke containing 100kg of C (carbon) as reducing material, and take coke containing 100kg of SiO 2 and Al 2 o 3 Kaolin is used as a modified material, where SiO in kaolin 2 and Al 2 o 3 The total weight is 50kg, of which SiO 2 with Al 2 o 3 The mass ratio is 1:0.2, and then the reduced material is crushed to a particle size of 5 mm, and the modified material is crushed to a particle size of 25 mm. Mix the above-mentioned steel slag, coke and kaolin evenly in the heating device, raise the temperature to 1350°C, and perform mechanical stirring at the same time. After the material is completely melted, keep it for 10 minutes. The molten iron and slag are separated naturally, and the molten iron is discharged, and the slag is cooled. Then carry out chemical analysis on the molten slag and test the gelling activity index of the tailings. The chemical analysis results are shown in Table 1, and the mortar strength test a...

Embodiment 2

[0020] Example 2, take 1000kg of massive steel slag, take coal powder containing 200kg of C (carbon) as reducing material, and take 1000kg of coal powder containing SiO 2 and Al 2 o 3 The fly ash is used as a modified material, wherein the SiO in the fly ash 2 and Al 2 o 3 The total weight is 100kg, SiO 2 with Al 2 o 3 The mass ratio is 1:0.1, and then the reduced material is crushed, and the particle size after crushing is 2 mm, and the modified material is crushed, and the particle size after crushing is 10 mm. Mix the steel slag, coal powder, and fly ash of the above weight evenly and place them in the heating device, raise the temperature to 1500°C, and carry out gas stirring at the same time. After the material is completely melted, keep it for 12 minutes. The molten iron and slag are separated naturally, and the molten iron is discharged, and the slag is discharged. Cool down. Then carry out chemical analysis on the molten slag and test the gelling activity index...

Embodiment 3

[0021] Example 3, take 1000kg of massive steel slag, take a mixture of pulverized coal and coke containing 350kg of C (carbon) as a reduction material, and take a mixture containing SiO 2 and Al 2 o 3 The sand is used as a modified material, and the SiO in the sand 2 and Al 2 o 3 The total weight is 150kg, of which SiO 2 with Al 2 o 3 The mass ratio is 1:0.3, and then the reduced material is crushed, and the particle size after crushing is 10 mm, and the modified material is crushed, and the particle size after crushing is 30 mm. Mix the steel slag, coal powder, coke, and sand of the above weight evenly and place them in the heating device, raise the temperature to 1550°C, and carry out mechanical stirring at the same time. After the material is melted, keep it for 13 minutes. The molten iron and slag are separated naturally, and the molten iron is discharged, and the slag is cooled. deal with. Then carry out chemical analysis on the slag and test the gelling activity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com