Glass reinforced plastic fiber pipe and manufacturing method thereof

A production method and technology of glass fiber yarn, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of insufficiently dense sand interlayer, limited thickness of quartz sand particles and interlayer, and low axial compressive strength of pipes. , to achieve the effect of enhancing stiffness and bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

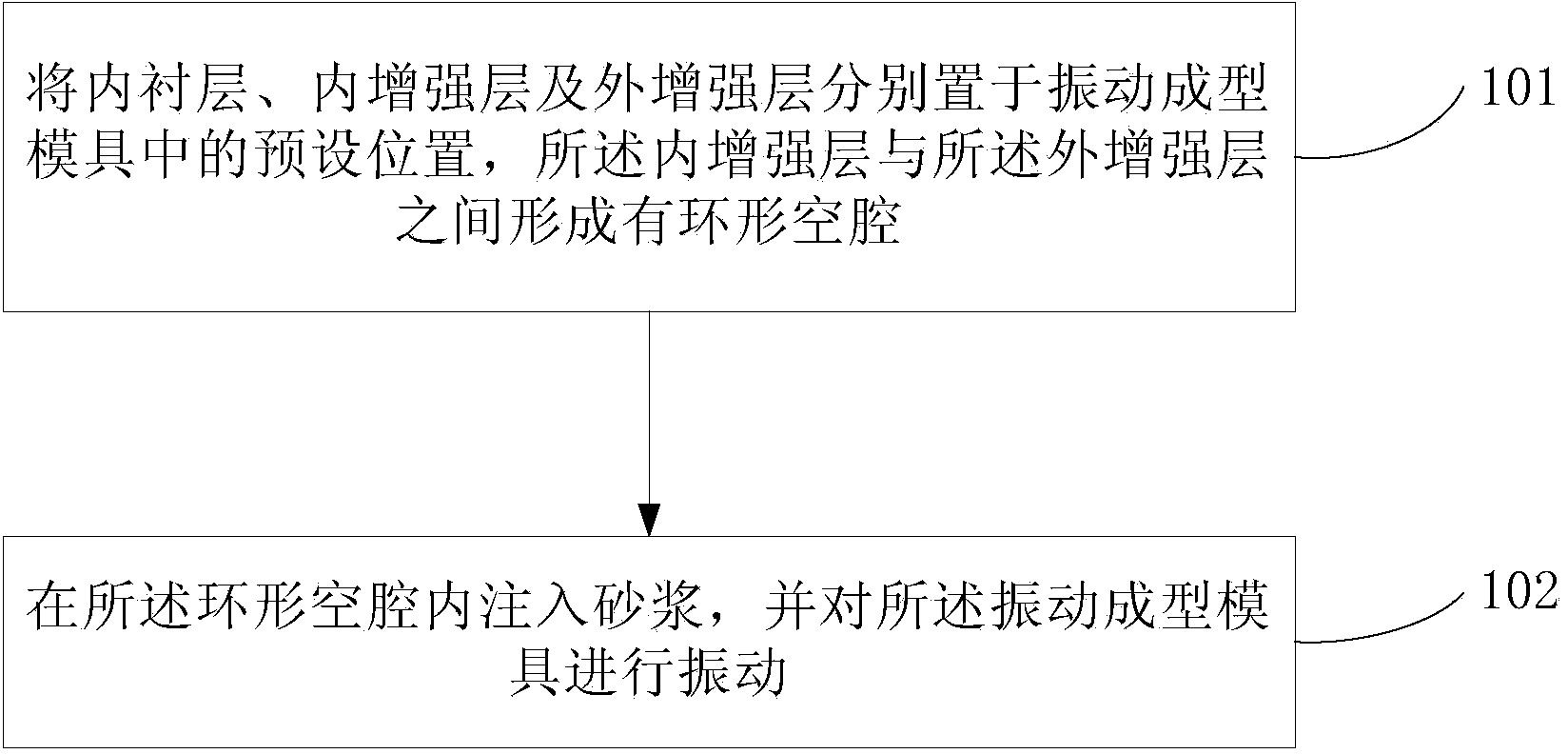

[0017] The embodiment of the present invention provides a kind of glass fiber reinforced plastic pipe manufacturing method, such as figure 1 Shown, this fiberglass fiber pipe manufacturing method comprises the following steps:

[0018] 101. Place the inner lining layer, the inner reinforcement layer and the outer reinforcement layer respectively at preset positions in the vibration forming mold, and an annular cavity is formed between the inner reinforcement layer and the outer reinforcement layer;

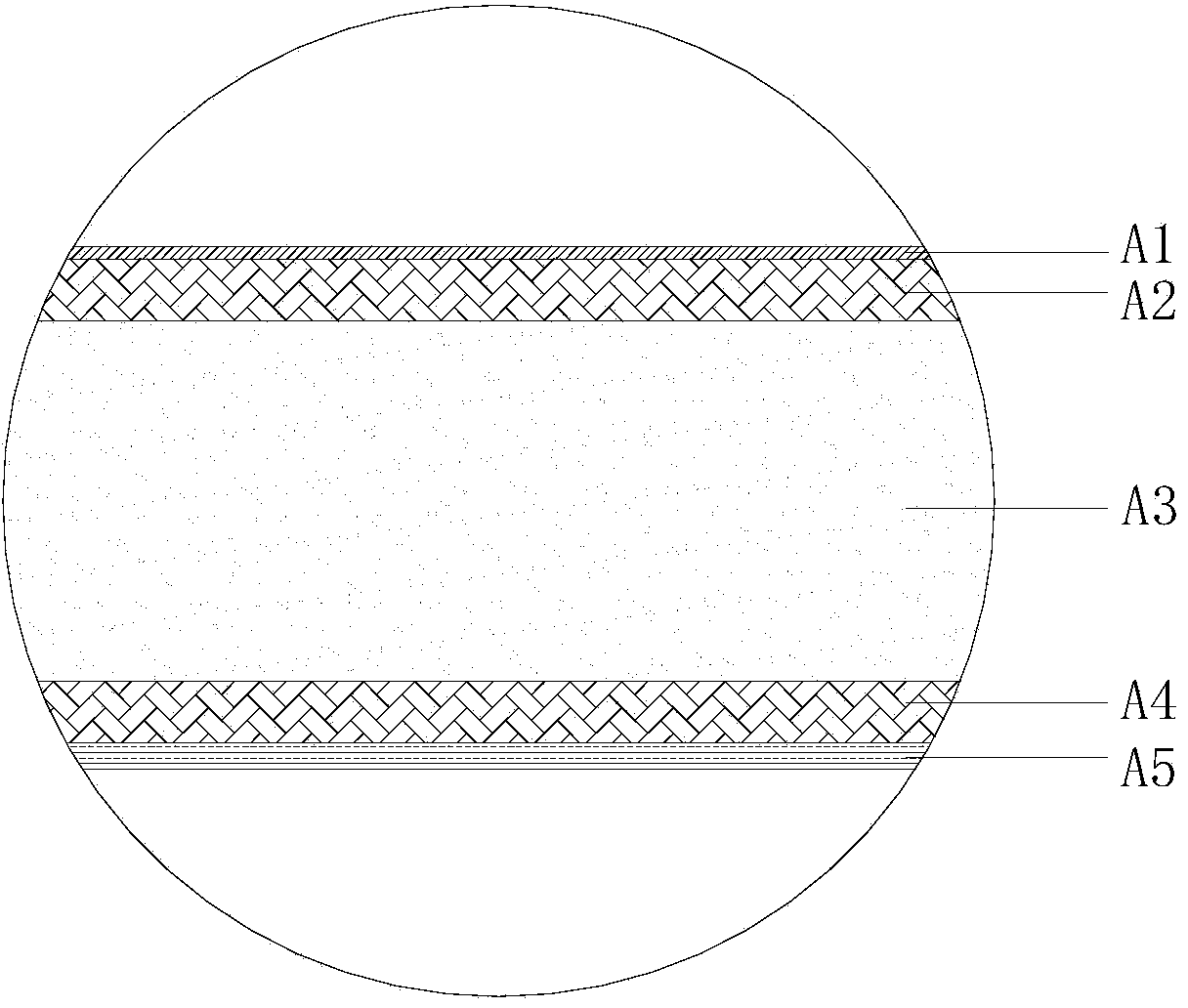

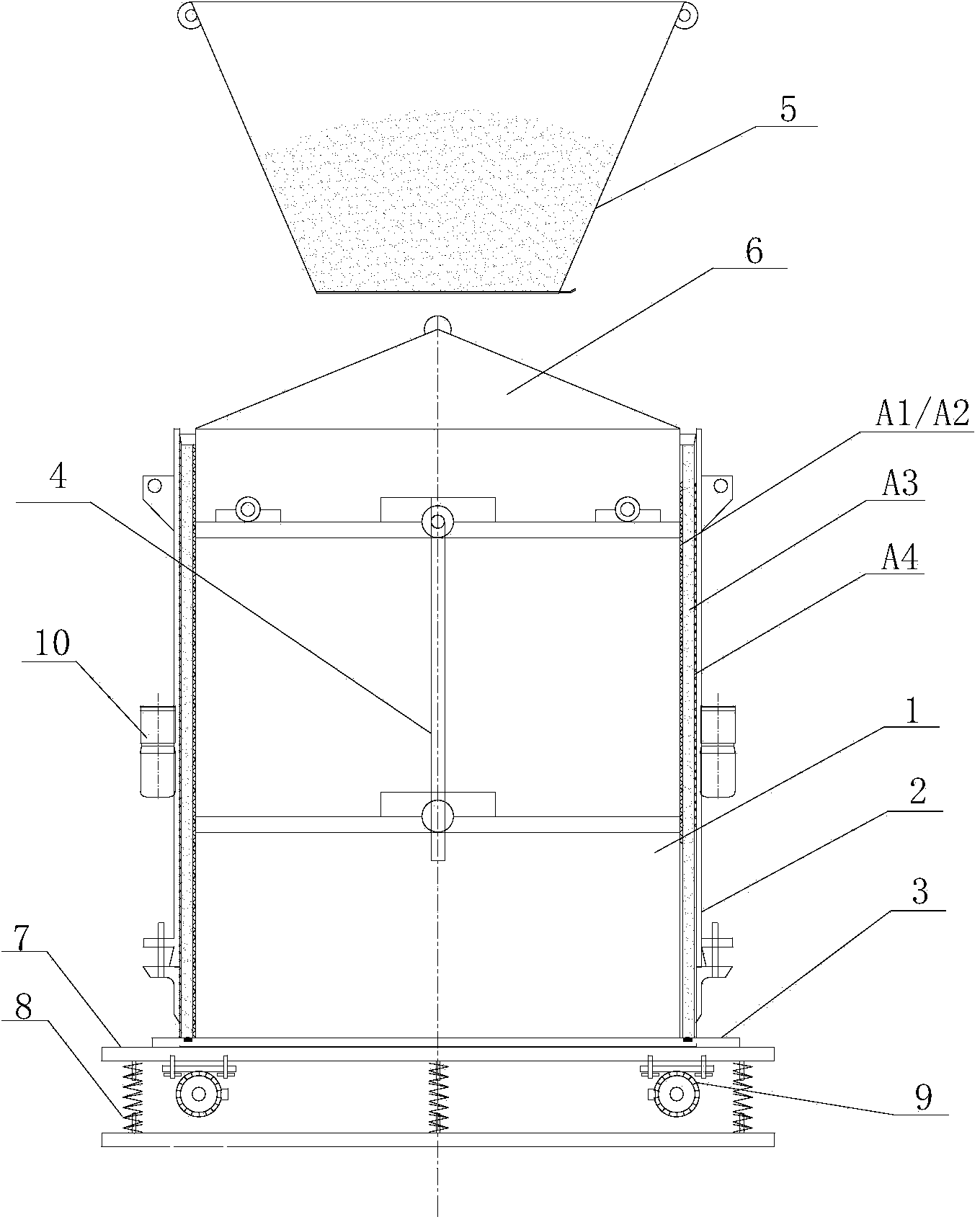

[0019] In this embodiment, the fiberglass fiber tube structure that needs to be made is as follows figure 2 As shown, from the inside to the outside are the inner lining layer A1, the inner reinforcement layer A2, the sand layer A3, the outer reinforcement layer A4 and the outer protection layer A5. Among them, the production process of the sand-filled layer A3 of the glass fiber reinforced plastic pipe is carried out in a set of vibration forming molds composed of an inner mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com