Mechanical dispersion fluidization drying method and equipment for coal slime

A drying equipment and drying method technology, applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of not being able to be used directly, high equipment cost, low heat utilization rate, etc., and achieve long contact time and dry The effect of long time and high utilization rate of calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

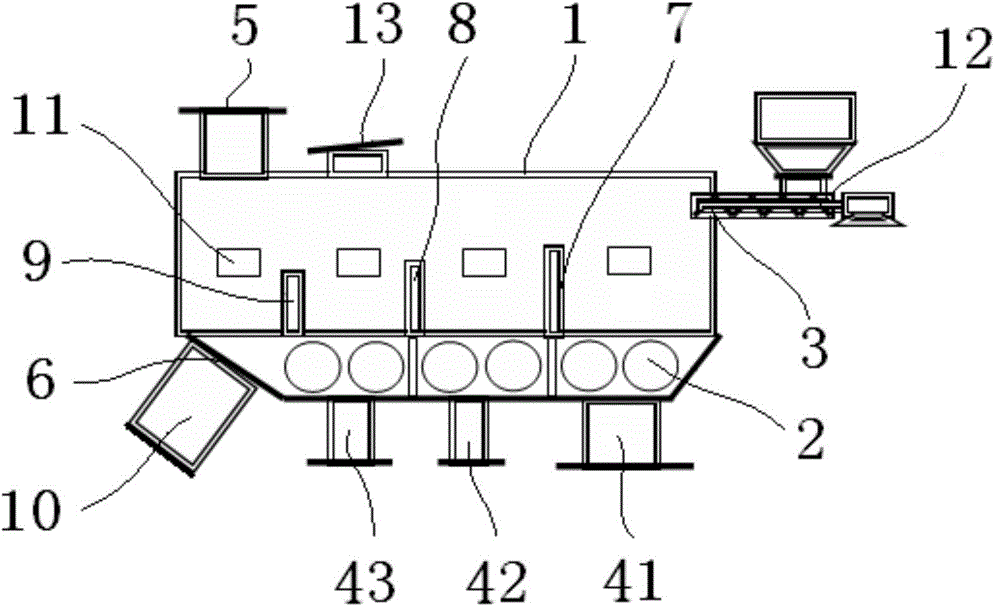

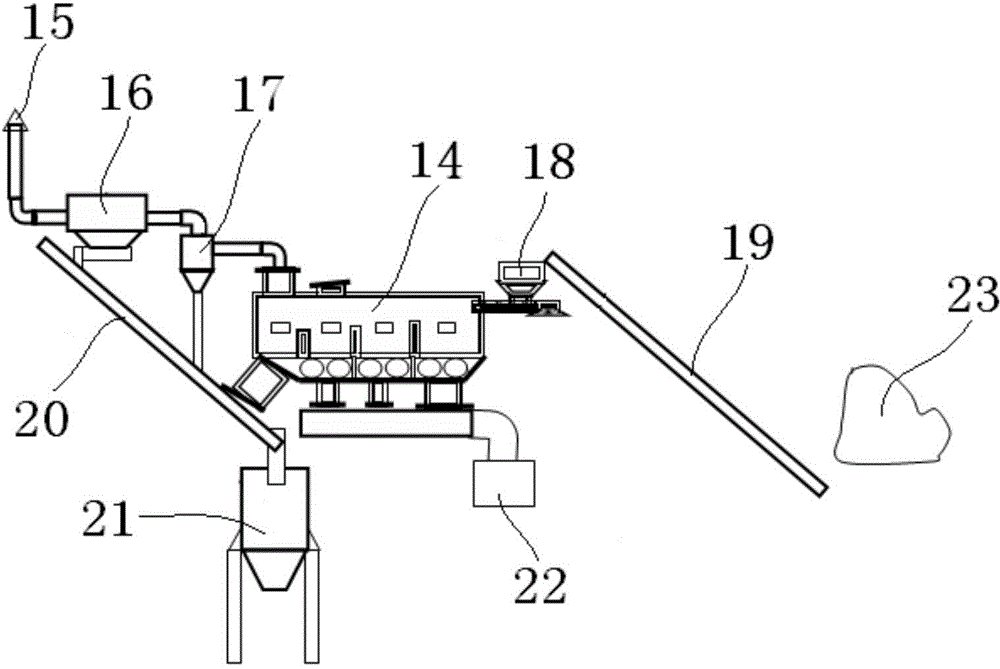

[0046] This embodiment provides a set of integral slime drying device using the mechanically dispersed fluidized drying equipment for slime of the present invention.

[0047] reference figure 2 , The drying device of this embodiment includes a slime feeding scraper 19, a slime silo 18, a mechanically dispersed and fluidized drying device for slime 14, a hot air stove 22, a finished product warehouse 21, a cyclone 17, a bag type Dust collector 16, exhaust chimney 15, dry product conveyor 20.

[0048] The coal slurry 23 to be dried with a water content of 15%-30% is conveyed into the coal slurry through the coal slurry feeding scraper 19 and the coal slurry silo 18 into the mechanical dispersing fluidized drying equipment 14, and the product after drying passes the coal slurry The discharge port 6 of the mechanically dispersed fluidized drying equipment 14 is directly transported into the finished product warehouse 21. Part of the small particle slime from the gas outlet 5 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com