Method and system for preparing steel slag ceramsite

A technology of steel slag and ceramsite, applied in the production of clay products, ceramic products, ceramic materials, etc., can solve the problems of limited application and poor stability of steel slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

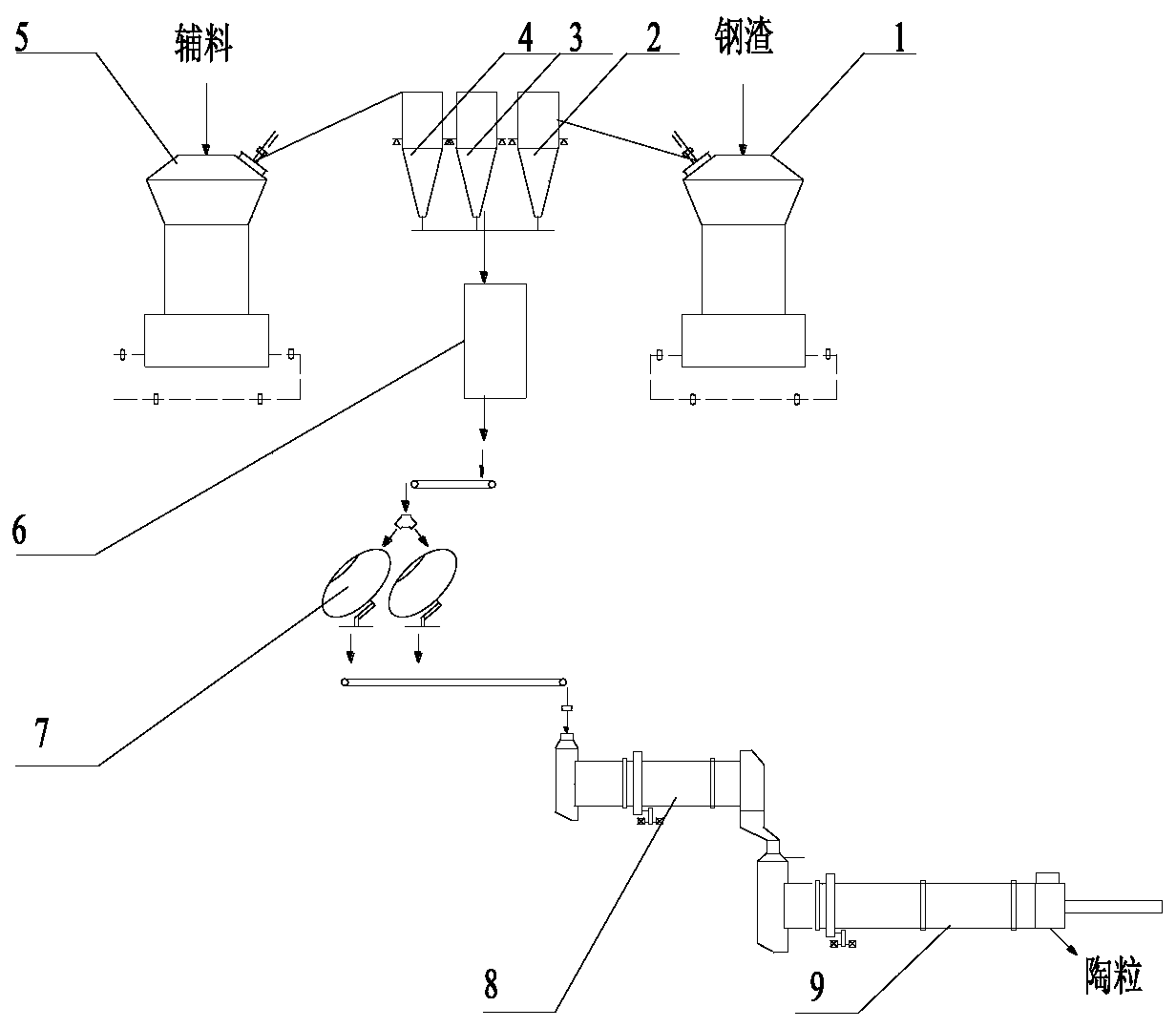

[0044] (1) Utilize the steel slag mill 1 to grind the steel slag to a 100-micron sieve residue of no more than 10%, make steel slag powder, and store it in the steel slag powder bin 2;

[0045] (2) Choose clay as an auxiliary material, use the auxiliary material mill 5 to grind it to a sieve of 100 microns to be no more than 10%, make auxiliary material powder, and store it in the auxiliary material bin 4;

[0046] (3) using dextrin as a binding agent, mixing it with water according to the ratio of (30wt%:70wt%) to make a bonding slurry, which is stored in the bonding slurry tank 3;

[0047] (4) 20wt% auxiliary material powder, 70wt% steel slag powder and 10wt% binder slurry are sent to granulator 6, mixed and granulated to form balls with a size of about 800 microns;

[0048] (5) Send the balls into the disc ball forming machine to form raw material balls with a size of 5000 microns to 10000 microns;

[0049] (6) Send the raw meal balls into the drum dryer 8 at 130°C to dry ...

Embodiment 2

[0052] (1) Utilize steel slag mill 1 to grind steel slag to 350 micron sieve and be no more than 10%, make steel slag powder, store in steel slag powder bin 2;

[0053] (2) choose blast furnace slag as auxiliary material, grind to 150 micron sieve and be no more than 10% through auxiliary material mill 5, make auxiliary material powder, store in auxiliary material bin 4;

[0054] (3) using polyvinyl alcohol as a binding agent, mixing it with water according to the ratio of (35wt%:65wt%) to make a bonding slurry, which is stored in the bonding slurry tank 3;

[0055] (7) 30wt% auxiliary material powder, 50wt% steel slag powder and 20wt% binder slurry are sent to granulator 6, mixed and granulated to form balls with a size of about 600 microns;

[0056] (8) Send the balls into the disc ball forming machine to form raw material balls with a diameter of 10,000 microns to 30,000 microns;

[0057] (9) Send the raw meal balls into a rotary drum dryer 8 at 150° C. to dry for 1 hour, ...

Embodiment 3

[0060] (1) Utilize the steel slag mill 1 to grind the steel slag to a 400-micron sieve of no more than 10%, make steel slag powder, and store it in the steel slag powder bin 2;

[0061] (2) select blast furnace slag and engineering spoil as auxiliary materials, after mixing according to the ratio of (30wt%:70wt%), grind to 100 micron sieves and be no more than 10% through auxiliary material mill 5, make auxiliary material powder, store in Auxiliary material warehouse 4;

[0062] (3) using dextrin as a binding agent, mixing it with water according to the ratio of (20wt%:80wt%) to make a bonding slurry, which is stored in the bonding slurry tank 3;

[0063] (4) 15wt% auxiliary material powder, 70wt% steel slag powder and 15wt% binder slurry are sent into the ball forming chamber 6, mixed and granulated to form balls with a size of about 500 microns;

[0064] (5) Send the balls into the disc ball forming machine to form raw material balls with a diameter of 8000 microns to 20000 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com