Process method for preparing similar cement clinkers by treating steel slag at thermal state in way of heat preservation

A technology of thermal insulation treatment and cement clinker, which is applied in the direction of cement production, etc., can solve the problems of steel slag stability and low activity, and achieve the effect of low cost, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

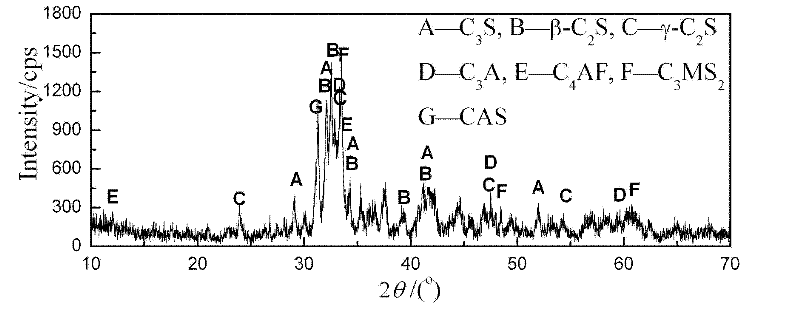

Embodiment 1

[0027] A process for preparing cement-like clinker from steel slag with thermal insulation treatment, and measuring SiO in steel slag 2 The mass fraction is 10% and Al 2 o 3 The mass fraction is 5%, and the process method comprises the following steps:

[0028] The first step is to mix the siliceous regulator with the high-temperature converter steel slag produced in the steelmaking process, and the added mass is 1% of the mass of the steel slag. The components and mass fractions of the siliceous regulator are: CaO: 10%, SiO 2 : 50%, Al 2 o 3 : 30%, MgO: 10%;

[0029] In the second step, the mixture of the siliceous regulator and the converter steel slag in the first step is subjected to heat preservation treatment, the heat preservation treatment temperature is 1350°C, and the heat preservation time is 60 minutes;

[0030] The third step is to quickly cool down to normal temperature by water cooling to obtain cement-like clinker.

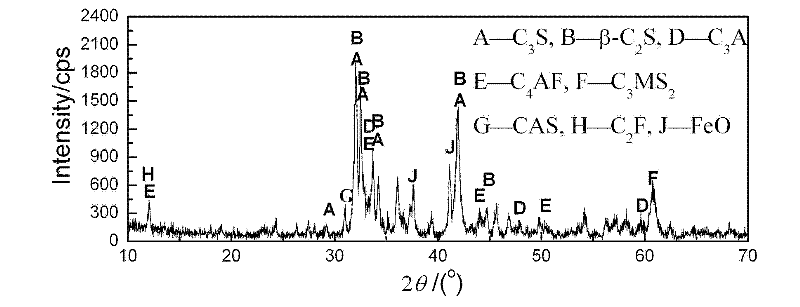

Embodiment 2

[0032] A process for preparing cement-like clinker from steel slag with thermal insulation treatment, and measuring SiO in steel slag 2 The mass fraction is 4% and Al 2 o 3 The mass fraction is 20%, and the process method comprises the following steps:

[0033] In the first step, the siliceous regulator is mixed with the high-temperature converter steel slag produced in the steelmaking process, and the added mass is 40% of the mass of the steel slag. The components and mass fractions of the siliceous regulator are: CaO: 50%, SiO 2 : 20%, Al 2 o 3 : 25%, MgO: 5%;

[0034]In the second step, the mixture of the siliceous regulator and the converter steel slag in the first step is subjected to heat preservation treatment, the heat preservation treatment temperature is 1550 ° C, and the heat preservation time is 10 minutes;

[0035] The third step is to quickly cool down to normal temperature by water cooling to obtain cement-like clinker.

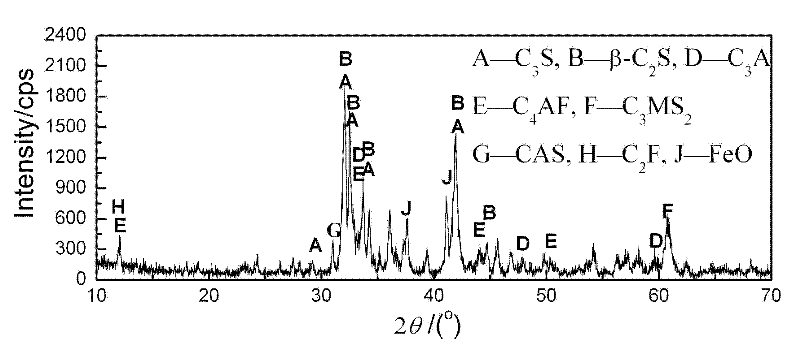

Embodiment 3

[0037] A process for preparing cement-like clinker from steel slag with thermal insulation treatment, and measuring SiO in steel slag 2 The mass fraction is 2% and Al 2 o 3 Mass fraction is 25%, and this process method comprises the following steps:

[0038] In the first step, the siliceous regulator is mixed with the high-temperature converter slag produced in the steelmaking process, and the added mass is 15% of the mass of the steel slag. The components and mass fractions of the siliceous regulator are: CaO: 30%, SiO 2 : 40%, Al 2 o 3 : 30%;

[0039] In the second step, the mixture of the siliceous regulator and the converter steel slag in the first step is subjected to heat preservation treatment, the heat preservation treatment temperature is 1450°C, and the heat preservation time is 30 minutes;

[0040] The third step is to quickly cool to normal temperature by air cooling to obtain cement-like clinker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com