Method for recovering phosphorus from urban mud anaerobic digestion solution

An anaerobic digestion and municipal sludge technology, applied in the field of phosphorus recovery, can solve the problems of not finding, low utilization efficiency of calcium source, and high recovery cost, and achieve the effects of reducing phosphorus load, expanding utilization channels, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

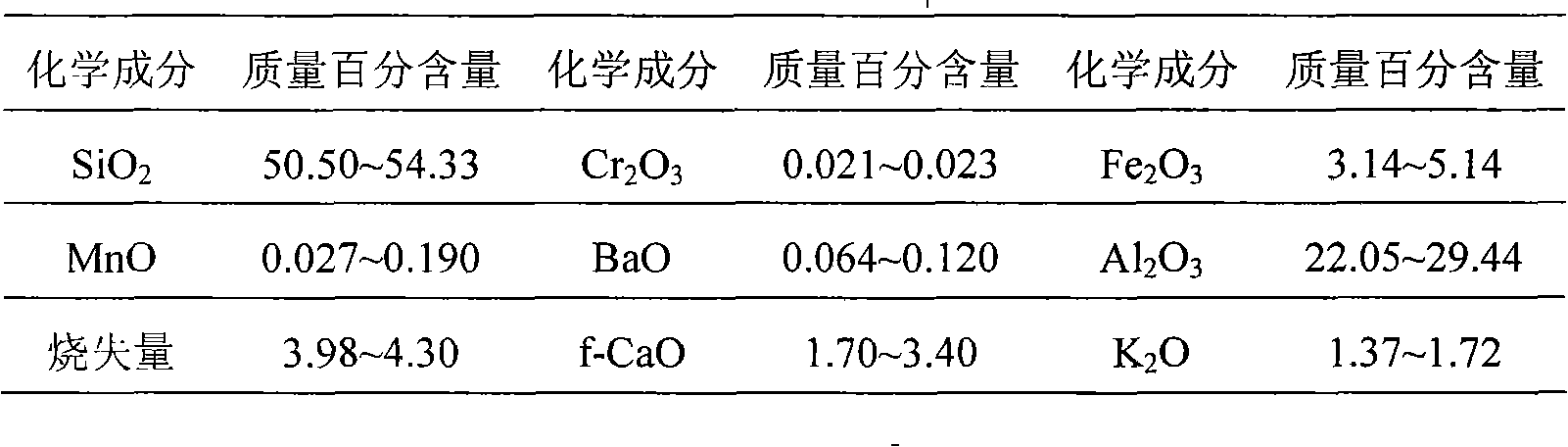

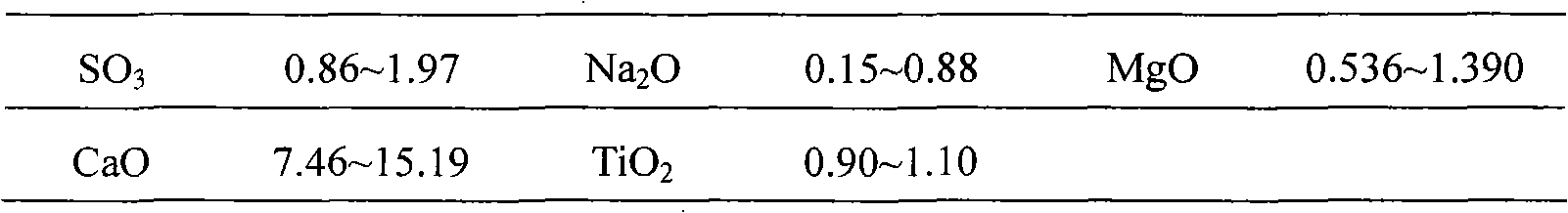

[0033] Take the fly ash from power plant A. After testing, the content of f-CaO in the fly ash is 1.70-3.40%. Mix fly ash and water at a ratio of 1:5, stir at 400rpm for 4h; let it stand for 16h, take the supernatant, filter the suspended particles with a filter membrane with a pore size of 0.45 microns, and obtain a leachate; after determination, Ca in the leachate 2+ The concentration reaches 1500.0mg / L.

[0034] After anaerobic digestion of municipal sludge, the supernatant was taken. After testing, the initial total phosphorus concentration was 94.5mg / L, and the initial orthophosphorus concentration was 89.0mg / L. Pretreatment was carried out, that is, the filter membrane with a pore size of 0.45 microns was used to filter and remove Suspend the particles, then add hydrochloric acid with a concentration of 5.9mol / L to acidify, adjust the pH value of the solution to 4.0, and obtain a pretreated digestive juice.

[0035] Mix the leaching solution and the pretreated digestive...

Embodiment 2

[0038] Take the fly ash from power plant B, and it is tested that the content of f-CaO in the fly ash is 1.70-3.40%. Mix fly ash and water at 1:40, stir at 50rpm for 0.5h; let it stand for 10h, take the supernatant, filter with a filter membrane with a pore size of 0.45 microns to remove suspended particles, and obtain a leachate; wherein, Ca in the leachate 2+ The concentration reached 640.0mg / L.

[0039] After anaerobic digestion of municipal sludge, the supernatant was taken. After testing, the initial total phosphorus concentration was 173.0mg / L, and the initial orthophosphorus concentration was 167.8mg / L. Pretreatment was carried out, that is, the filter membrane with a pore size of 0.45 microns was used to filter and remove Suspend the particles, then add hydrochloric acid with a concentration of 8.85mol / L to acidify, adjust the pH value of the solution to 3.8, and obtain the pretreated digestive juice.

[0040] According to the molar ratio of calcium and phosphorus in ...

Embodiment 3

[0043] Take the fly ash from power plant A. After testing, the content of f-CaO in the fly ash is 1.70-3.40%. Mix fly ash and water at a ratio of 1:20, stir at 200rpm for 1h; let it stand for 12h, take the supernatant, filter the suspended particles with a filter membrane with a pore size of 0.45 microns, and obtain a leachate; wherein, Ca in the leachate 2+ The concentration reached 1020.0mg / L.

[0044] After anaerobic digestion of municipal sludge, the supernatant was taken. After testing, the initial total phosphorus concentration was 107.6mg / L, and the initial orthophosphorus concentration was 105.9mg / L. Pretreatment was carried out, that is, the filter membrane with a pore size of 0.45 microns was used to filter and remove Suspend the particulate matter, then add hydrochloric acid with a concentration of 8.85mol / L to acidify, adjust the pH value of the solution to 2.0, and obtain a pretreated digestive juice.

[0045] Mix the leaching solution and the pretreated digestiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com