Method and system for producing steel slag sintered brick

A technology of sintered bricks and steel slag, applied in clay products, applications, household appliances, etc., can solve the problems of poor stability and limited application of steel slag, and achieve the effect of solving the problem of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

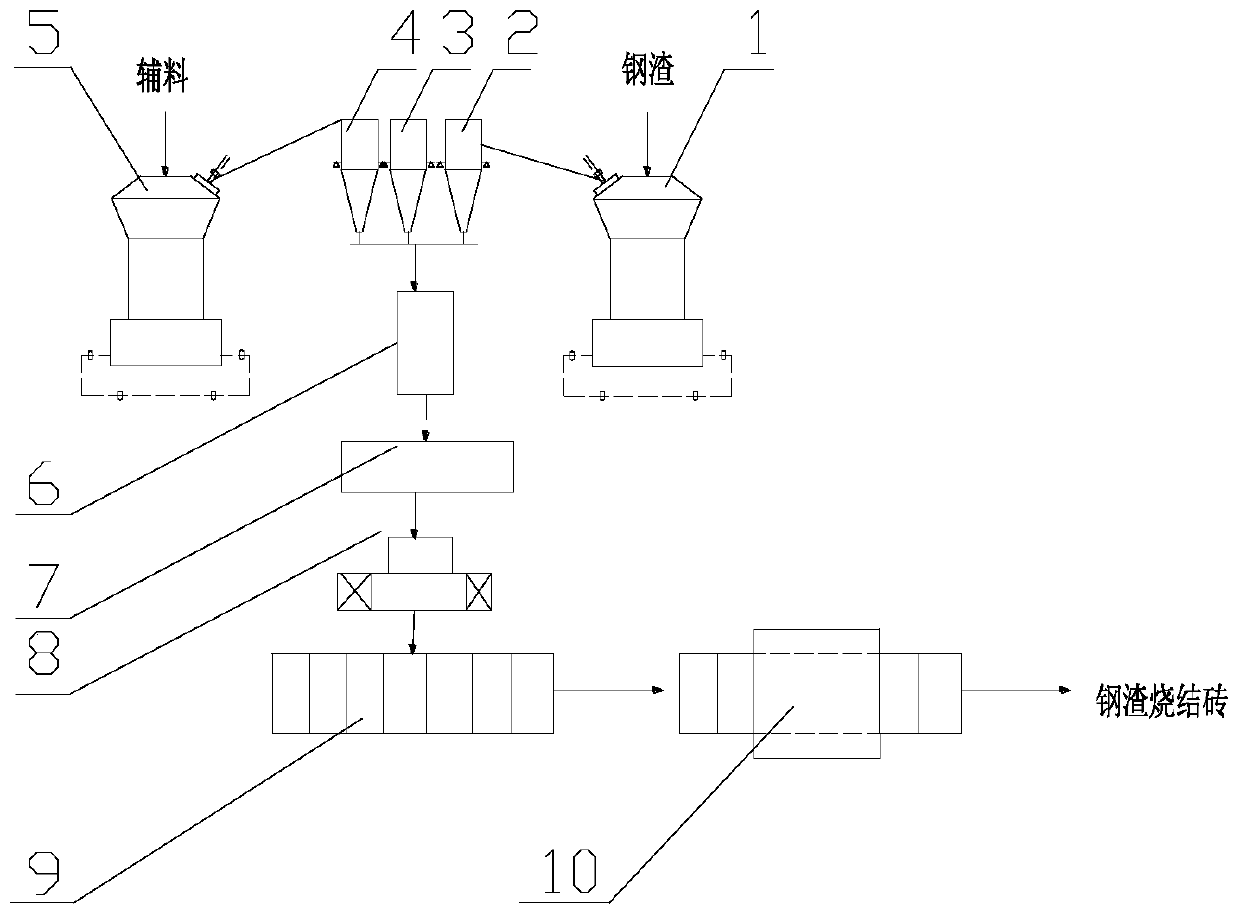

[0045] (1) use the steel slag mill 1 to grind the steel slag to a 450-micron sieve residue of not more than 10%, make the steel slag powder, and store it in the steel slag powder bin 2;

[0046] (2) Select engineering spoil as auxiliary material, use auxiliary material mill 5 to grind it to a 100-micron sieve residue of not more than 10%, make auxiliary material powder, and store in auxiliary material warehouse 4;

[0047] (3) take clay as binder, mix it with water according to the ratio of (50wt%:50wt%) to make binding slurry, and store it in binding slurry tank 3;

[0048] (4) 25wt% auxiliary powder, 70wt% steel slag powder and 5wt% binder slurry are sent into the pelletizing chamber 6, mixed and granulated to form raw pellets of about 800 microns;

[0049] (5) The raw pellets are aged in the aging chamber 7 for 1 day, and after being formed by the brick press 8, they are then sent to the drying chamber 9 at 150° C. for drying for 1 hour, and fired under the condition of 115...

Embodiment 2

[0051] (1) use the steel slag mill 1 to grind the steel slag to a 350-micron sieve residue of not more than 10%, make the steel slag powder, and store it in the steel slag powder bin 2;

[0052] (2) Select blast furnace slag as auxiliary material, grind to 150 micron sieve residue not more than 10% by auxiliary material mill 5, make auxiliary material powder, and store in auxiliary material warehouse 4;

[0053] (3) take polyvinyl alcohol as a binder, mix it with water according to the ratio of (30wt%:70wt%) to make a bonding slurry, and store it in the bonding slurry tank 3;

[0054] (4) 30wt% auxiliary powder, 60wt% steel slag powder and 10wt% binder slurry are sent into the pelletizing chamber 6, mixed and granulated to form raw pellets of about 1000 microns;

[0055] (5) The raw pellets are aged in the aging chamber 7 for 3 days, and after being formed by the brick press 8, they are then sent to the drying chamber 9 at 150° C. for drying for 1 hour, and are fired under the...

Embodiment 3

[0057] (1) use the steel slag mill 1 to grind the steel slag to a 450-micron sieve residue of not more than 10%, make the steel slag powder, and store it in the steel slag powder bin 2;

[0058] (2) Select blast furnace slag and engineering spoil as auxiliary materials, mix them according to the ratio of (30wt%: 70wt%), and grind them to a 100-micron sieve residue of not more than 10% by auxiliary material mill 5 to prepare auxiliary material powder and store it in In the auxiliary material warehouse 4;

[0059] (3) take dextrin as a binder, mix it with water according to the ratio of (20wt%:80wt%) to make a binding slurry, and store it in the binding slurry tank 3;

[0060](4) 20wt% auxiliary powder, 70wt% steel slag powder and 10wt% binder slurry are sent into the pelletizing chamber 6, mixed and granulated to form raw pellets of about 600 microns;

[0061] (5) The raw pellets are aged in the aging chamber 7 for 5 days, and after being formed by the brick press 8, they are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com