Steel smelting tailing treatment process

A treatment process, iron and steel smelting technology, applied in the field of iron and steel smelting tailings treatment process, can solve the problems of lack of treatment methods for tailings, low utilization rate of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

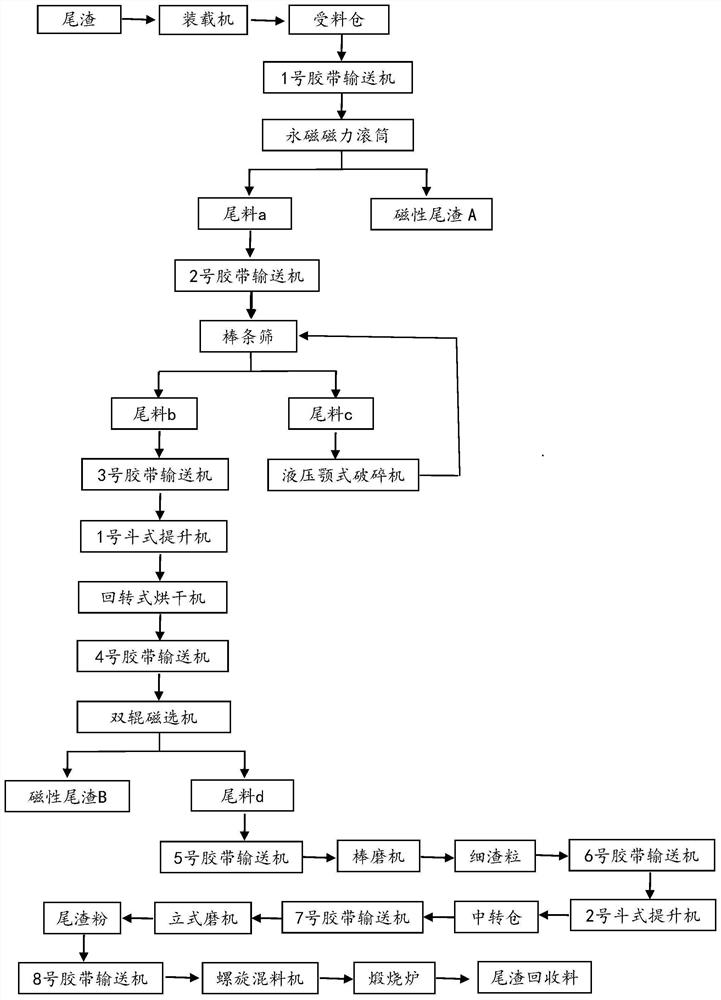

[0025] refer to figure 1 , a iron and steel smelting tailings treatment process, including the following steps: sending the tailings to the receiving bin through the loader, and then sending the tailings to the permanent magnetic drum through the No. 1 belt conveyor for initial magnetic separation, and the magnetic strength is 1000mT, separate the magnetic tailings A and tailings a, and the tailings a is transported to the bar sieve by No. 2 belt conveyor for screening to obtain tailings b with a particle size of less than 50mm and tails c with a particle size greater than 50mm. The tailings c are sent to the hydraulic jaw crusher for crushing, and then sent to the bar screen again after crushing, and the circular screening is continued. The tailings b are sent to the conveyor through No. 3 belt conveyor and No. 1 bucket elevator in turn. Drying is carried out in a rotary dryer. The high-temperature flue gas required by the rotary dryer is provided by a fluidized fluidized fur...

Embodiment 2

[0028]A treatment process for iron and steel smelting tailings, including the following steps: sending the tailings to the receiving bin through a loader, and then sending the tailings to a permanent magnetic drum through a No. 1 belt conveyor for initial magnetic separation, and the magnetic strength is 1200mT , the magnetic tailings A and tailings a are separated, and the tailings a is transported to the bar sieve by No. 2 belt conveyor for screening to obtain tailings b with a particle size less than 80 mm and tails c with a particle size greater than 80 mm. The tailings c are sent to the hydraulic jaw crusher for crushing, and then sent to the bar screen again after crushing to continue the circular screening. The tailings b are sent to the rotary conveyor through No. 3 belt conveyor and No. 1 bucket elevator in turn. The high temperature flue gas required by the rotary dryer is provided by a fluidized fluidized furnace, which uses coal gangue as fuel, and the dried tailing...

Embodiment 3

[0030] A treatment process for iron and steel smelting tailings, including the following steps: sending the tailings to the receiving bin through a loader, and then sending the tailings to a permanent magnetic drum through a No. 1 belt conveyor for initial magnetic separation, and the magnetic strength is 1500mT , the magnetic tailings A and tailings a are separated, and the tailings a is transported to the bar sieve by No. 2 belt conveyor for screening to obtain tailings b with a particle size less than 100 mm and tails c with a particle size greater than 100 mm. The tailings c are sent to the hydraulic jaw crusher for crushing, and then sent to the bar screen again after crushing to continue the circular screening. The tailings b are sent to the rotary conveyor through No. 3 belt conveyor and No. 1 bucket elevator in turn. The high temperature flue gas required by the rotary dryer is provided by a fluidized fluidized furnace, which uses coal gangue as fuel, and the dried tail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com