Device preparation method for synchronously generating hydrogen energy and clean water by utilizing light energy

A technology for cleaning water and devices, applied in chemical instruments and methods, nanotechnology for materials and surface science, general water supply conservation, etc., can solve problems such as difficult to reduce complexity cost and energy conversion timeliness, and achieve realization Maximize utilization, reduce heat loss, and reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

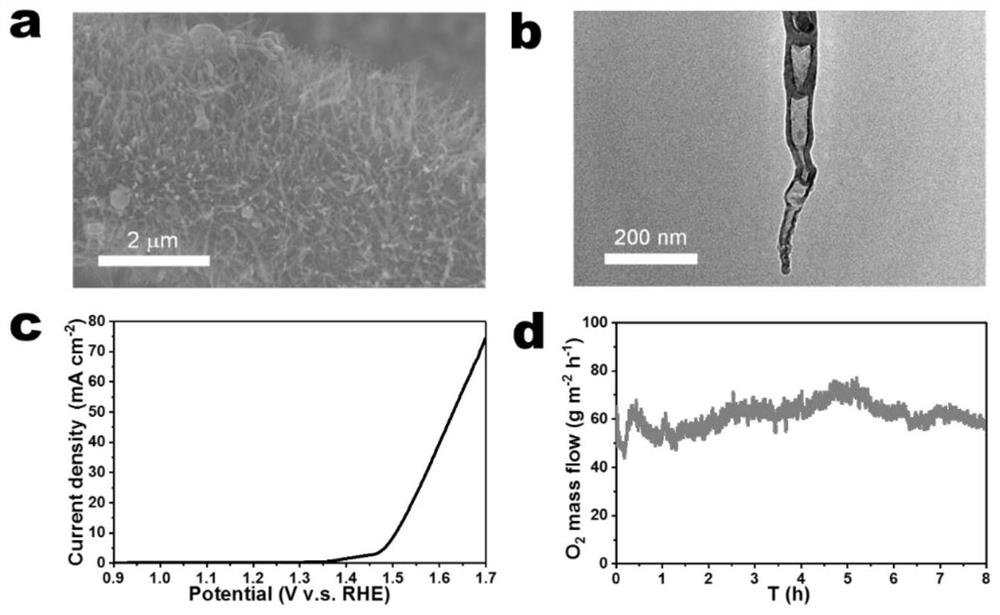

[0034] (1) Synthesis of bamboo-shaped carbon nanotube-wrapped FeNi 3 Oxygen evolution electrocatalyst, the steps are:

[0035]1) 0.27g ferric nitrate (Fe(NO 3 9H 2 O) 3 ,0.6g nickel nitrate (Ni(NO 3 9H 2 O) 3 and 0.84g of urea were added to 225ml of distilled water, and stirred for 4h.

[0036] 2) Immerse the melamine sponge in the solution obtained in step 1), and age it in the air for 12 hours (more than 5 hours are acceptable).

[0037] 3) Put the aged melamine sponge obtained in step 2) into an oven for drying, the drying condition: 100°C, 12h.

[0038] 4) Carbonize the product obtained in step 3) in nitrogen (carbonization conditions: 900°C, 2h, heating rate: 5°C / min).

[0039] 5) Grinding the product obtained in step 4) to powder.

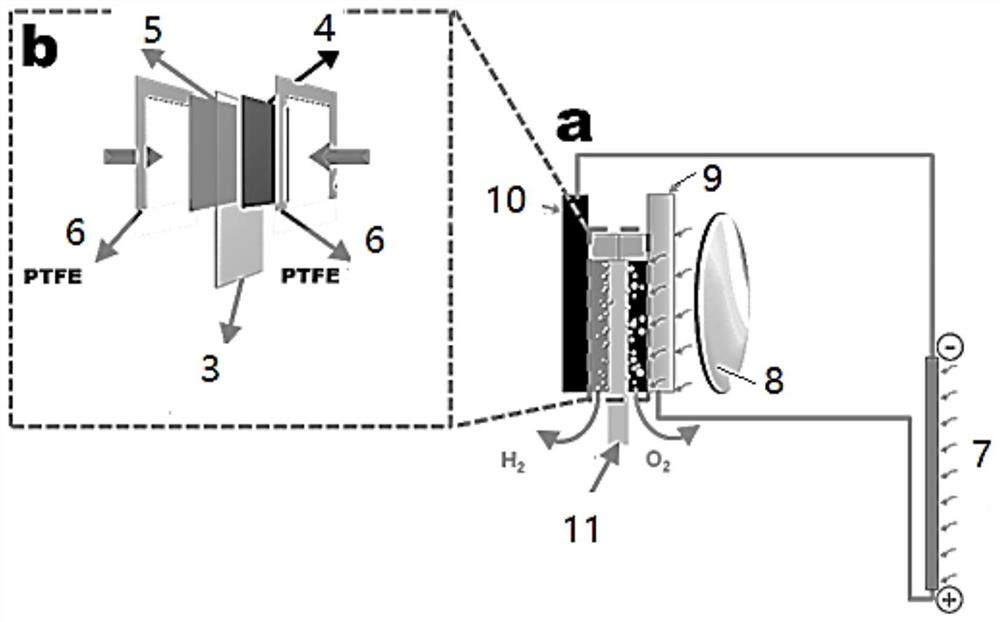

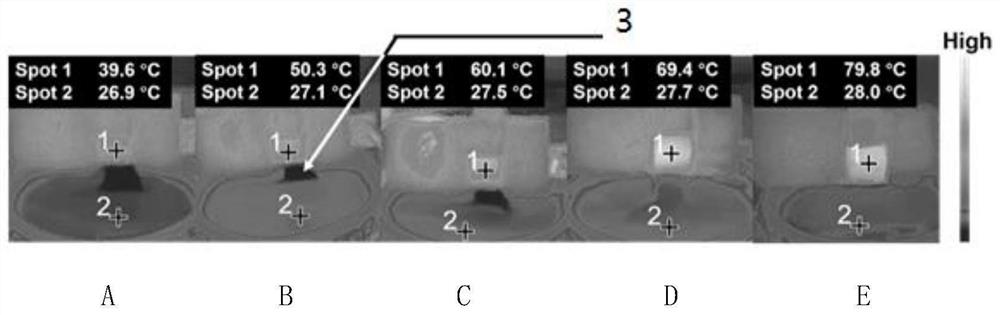

[0040] (2) Construction of the device

[0041] 2-1) 10 mg of the synthesized oxygen evolution electrocatalyst was added dropwise to 400 μL of ethanol solution, 50 μL of naphthol solution was added as a binder, and the mixture was so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com