A kind of composite polishing liquid for blue glass filter and preparation method thereof

A compound polishing and optical filter technology, which is applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of time-consuming and material-consuming, low pass-through rate of blue glass processing, and expensive machine investment, etc., to achieve high polishing efficiency, Improve polishing efficiency and surface quality, and the effect of polishing and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

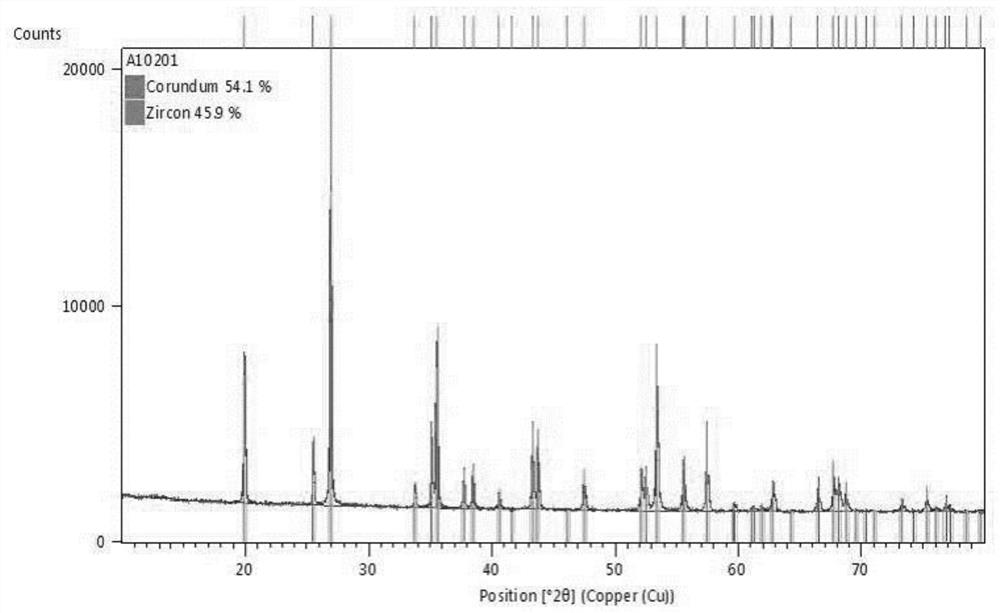

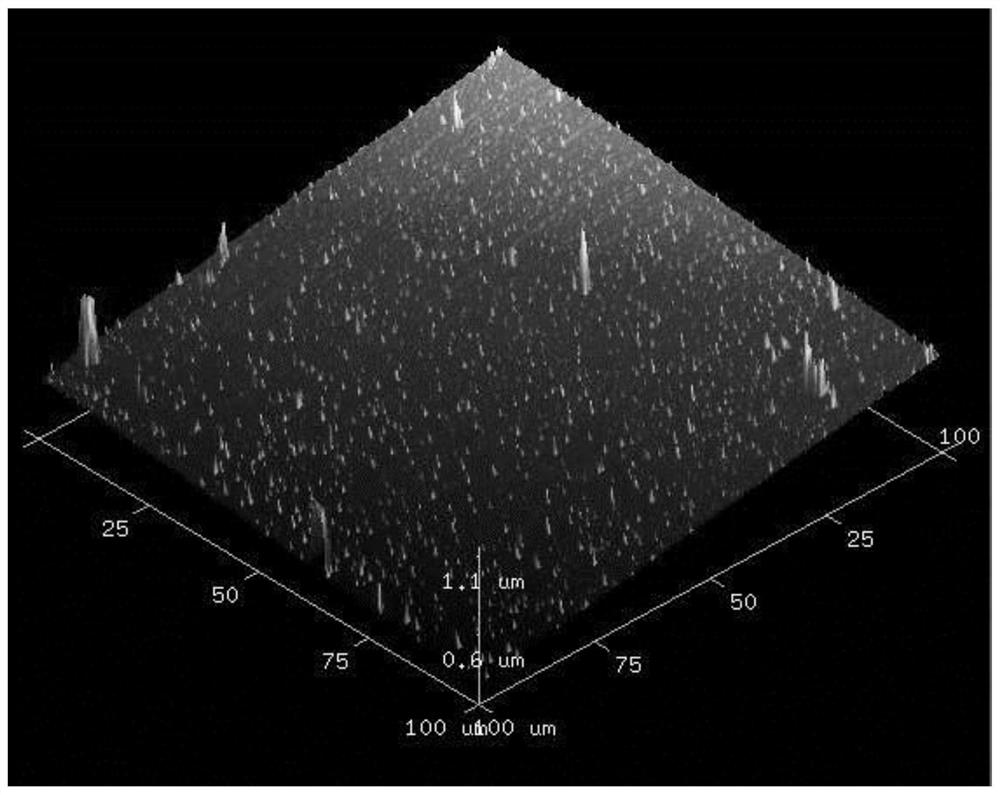

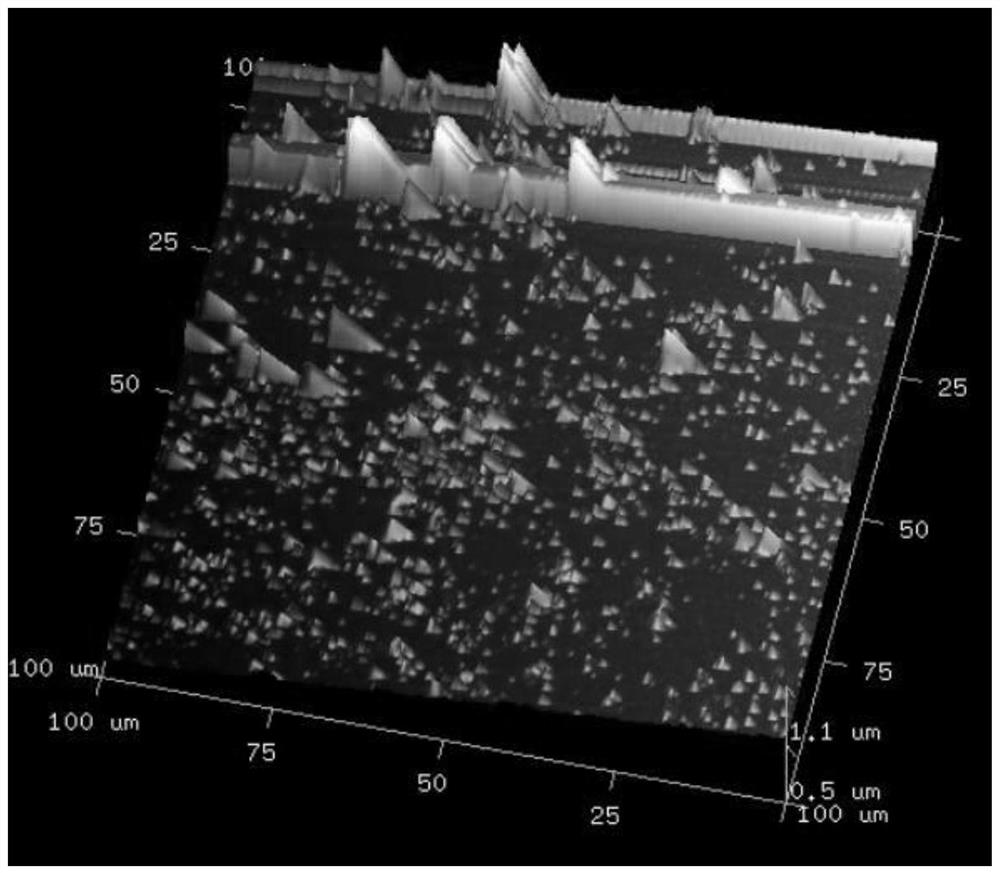

[0033] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

[0034] The present invention provides a composite polishing solution for a blue glass filter comprising aluminum hydroxide, zirconium hydroxide, and silica sol, and liquid base, surfactant, defoamer, and water.

[0035] The present invention also provides a method for preparing a composite polishing fluid for a blue glass filter, comprising the steps of:

[0036] (1) Add mass ratio of 5% deionized water in the reaction kettle, adding mass ratio of 40% aluminum hydroxide (γ-Al (OH) 3 Or γ-AlOOH or α-Al (OH) 3 After stirring 20 min, the control specific gravity is between 1.1-1.2, and the mass ratio of 30% is slowly added, and the mass ratio is 20% silica sol after stirring, and the mass ratio is 5% carboxus. Methylcellulose and polyethylene glycol are used as a fusion agent, stirred, warmed to 50-80 ° C for 1 hour.

[0037] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com