Process method for preparing chlorosulfonyl isocyanate through continuous reactive distillation

A technology of chlorosulfonyl isocyanate and chloropyrothiol isocyanate, which is applied in the field of continuous reactive distillation to prepare chlorosulfonyl isocyanate, can solve the problem that the content of sulfur trioxide cannot be effectively reduced, and achieve an increase in mass fraction and an increase in yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

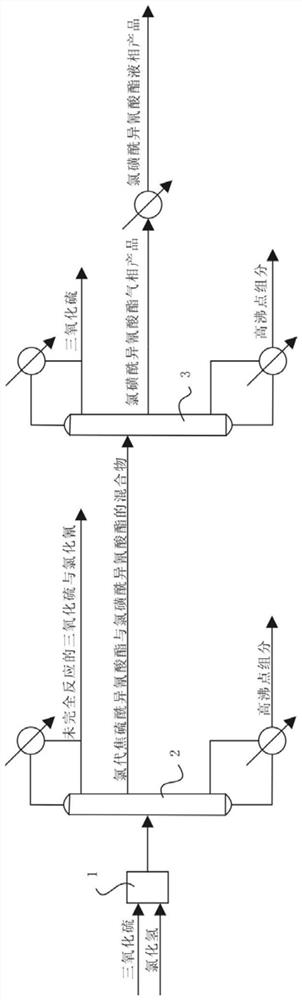

[0030] Example 1: Sulfur oxide and cyanogen chloride are dosed in a molar ratio of 1.2:1. After the preliminary reaction in the reactor, the reaction liquid continuously enters the first reaction rectification tower, and the incompletely reacted sulfur trioxide is extracted from the top of the tower. With cyanogen chloride, the high boiling point components generated by the side reaction are extracted from the tower kettle, and the mixture of chlorinated pyrosulfonyl isocyanate and chlorosulfonyl isocyanate is extracted from the side line liquid phase. The mixture continuously enters the second reactive distillation tower, and the sulfur trioxide produced by the decomposition of chlorinated pyrosulfonyl isocyanate is extracted from the top of the second reactive distillation column, a small amount of high boiling point components are extracted from the bottom of the column, and qualified Chlorosulfonyl isocyanate products. The sulfur trioxide and cyanogen chloride obtained fro...

Embodiment 2

[0036] Example 2: Sulfur oxide and cyanogen chloride are mixed in a molar ratio of 1.5:1. After the initial reaction in the reactor, the reaction liquid continuously enters the first reactive distillation tower, and the incompletely reacted sulfur trioxide is extracted from the top of the tower. With cyanogen chloride, the high boiling point components generated by the side reaction are extracted from the tower kettle, and the mixture of chlorinated pyrosulfonyl isocyanate and chlorosulfonyl isocyanate is extracted from the side line liquid phase. The mixture continuously enters the second reactive distillation tower, and the sulfur trioxide produced by the decomposition of chlorinated pyrosulfonyl isocyanate is extracted from the top of the second reactive distillation column, a small amount of high boiling point components are extracted from the bottom of the column, and qualified Chlorosulfonyl isocyanate products. The sulfur trioxide and cyanogen chloride obtained from the...

Embodiment 3

[0042]Embodiment 3: Sulfur oxide and cyanogen chloride are dosed in a molar ratio of 1.8:1. After preliminary reaction in the reactor, the reaction liquid continuously enters the first reaction rectification tower, and the incompletely reacted sulfur trioxide is extracted from the top of the tower. With cyanogen chloride, the high boiling point components generated by the side reaction are extracted from the tower kettle, and the mixture of chlorinated pyrosulfonyl isocyanate and chlorosulfonyl isocyanate is extracted from the side line liquid phase. The mixture continuously enters the second reactive distillation tower, and the sulfur trioxide produced by the decomposition of chlorinated pyrosulfonyl isocyanate is extracted from the top of the second reactive distillation column, and a small amount of high-boiling point components are extracted from the bottom of the column, and the qualified gas phase is extracted from the side line. Chlorosulfonyl isocyanate products. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com