A three-dimensional ordered macroporous transition metal oxide composite material and its preparation method and catalyst application

A transition metal, three-dimensional ordered technology, applied in the field of three-dimensional ordered macroporous transition metal oxide composite materials and their preparation, can solve the problems of further improvement of electrochemical performance, complex synthesis process, strict synthesis conditions, etc. Application potential and industrial value, high energy density, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] S1: Cut the purchased commercial carbon cloth to a certain size, then soak it in a mixture of 98% concentrated sulfuric acid and 12mol / L hydrochloric acid, and reflux it in a fume hood at 80°C for 12 hours;

[0052] S2: After the reaction, disperse a certain amount of PS microspheres (130nm in size) in water, and mix them uniformly by ultrasonic. Use a dropper to drip onto the carbon cloth, heat and evaporate to remove water at a certain temperature in an oven;

[0053] S3: A certain amount of potassium permanganate and carbon powder were evenly dispersed in water, and the carbon cloth treated in S2 was immersed in it, hydrothermally synthesized at 90°C for 12 hours, and then dried at high temperature.

[0054] S4: Another PS microsphere with a smaller pore size (70nm in size) is used to disperse in water, and mix uniformly by ultrasonic. Use a dropper to drip onto the carbon cloth with manganese dioxide, and heat at a certain temperature in an oven to evaporate and re...

Embodiment 2-5

[0057] Embodiment 2-5: the investigation of material consumption ratio in the step S5

[0058] Embodiment 2-5: except that in step S5, the molar ratio of nickel nitrate, ferric nitrate hydrate, ammonium fluoride and urea is replaced by 1:1:1:1, 1:1:1:2, 1:1: 1:3, 1:2:1:2, other operations are all the same, thus repeat the operation of Example 1, thereby carrying out the examples 2-5 in sequence, and the obtained carbon materials are named M2, M3, M4, M5.

Embodiment 6-7

[0059] Embodiment 6-7: the investigation of roasting temperature in the step S6

[0060] Example 6-7: Except that the high-temperature calcination treatment temperature in step S6 was replaced from 300°C to 300°C and 500°C respectively, other operations were unchanged, so that Example 1 was repeated to obtain Example 6-7 in sequence , and the resulting carbon materials are therefore named M6, M7.

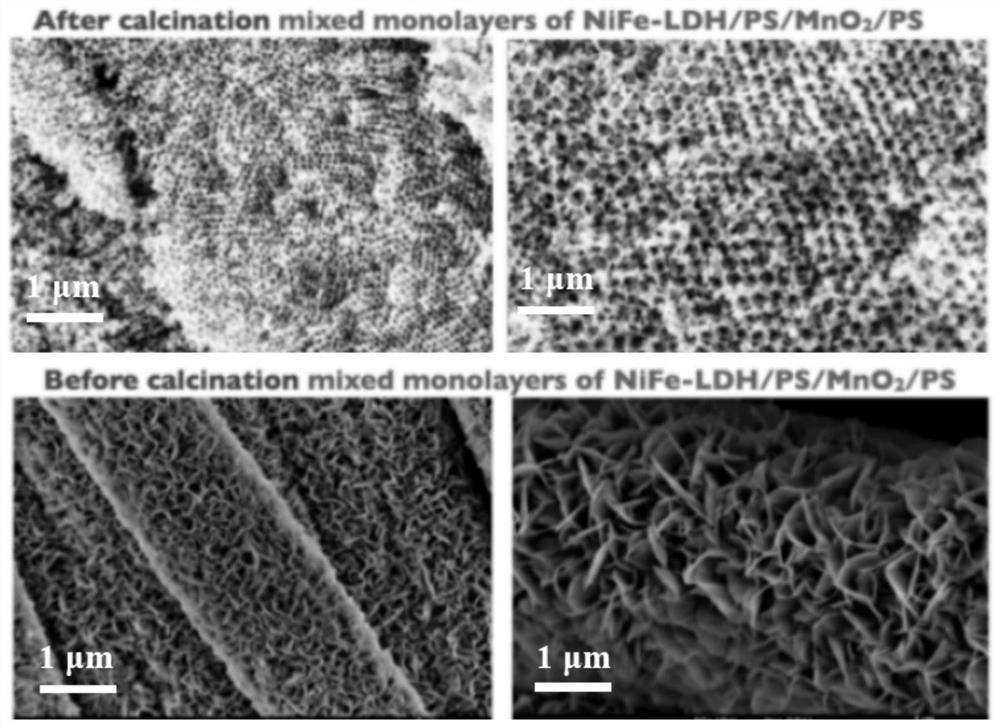

[0061] Microscopic representation

[0062] The three-dimensional ordered macroporous transition metal oxide M1 and its precursor obtained in Example 1 were microscopically characterized by a number of different means, and the results are as follows:

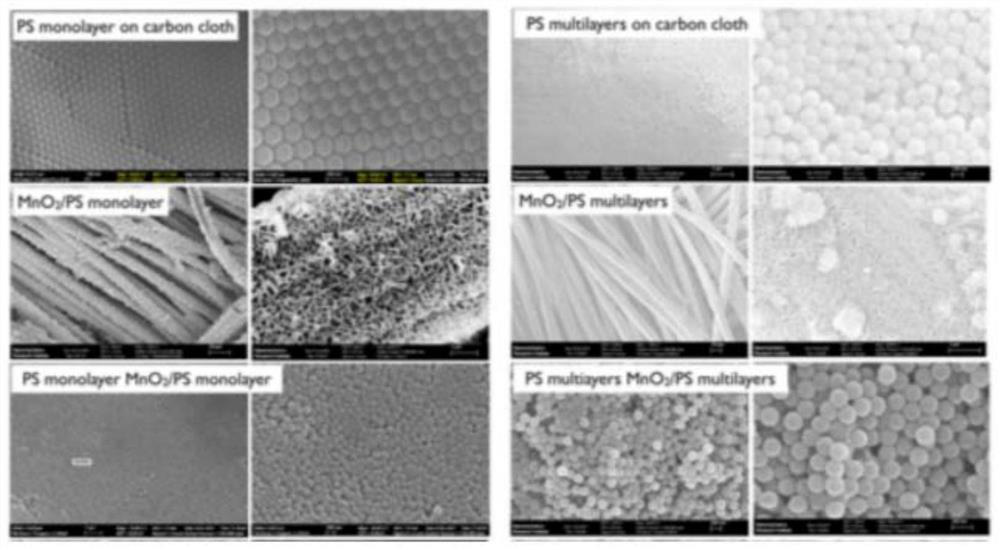

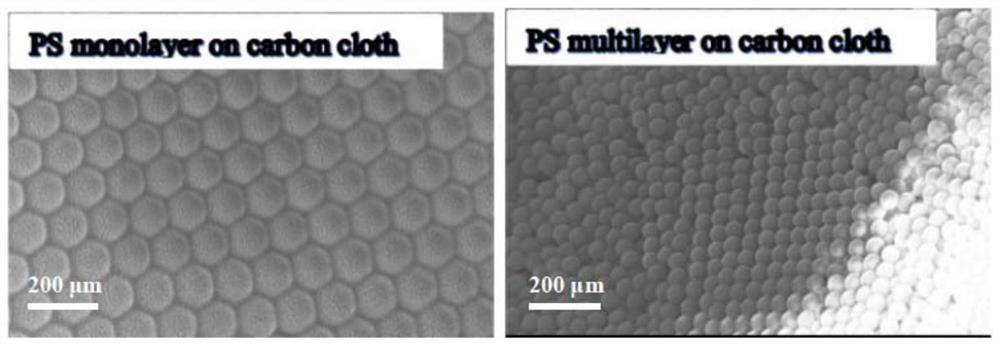

[0063] 1. By figure 1 It can be seen from the SEM image that the template PS microsphere layer unit size in the M1 precursor is uniform, highly ordered and dense. By changing the synthesis process, PS microspheres with mixed multilayer structure were obtained, which were densely arranged and agglomerated.

[0064] 2. By figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com