Preparation method of in-situ synthesis ZTA particle reinforced steel-based configuration composite material

A particle-enhanced, in-situ self-generating technology, applied in the field of metal matrix composite materials, can solve the problems of poor wettability between ZTA ceramic particles and steel melt, easy peeling of the composite area of the surface composite material, and low interfacial bonding strength. The effect of high interface bonding strength, not easy to peel off, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

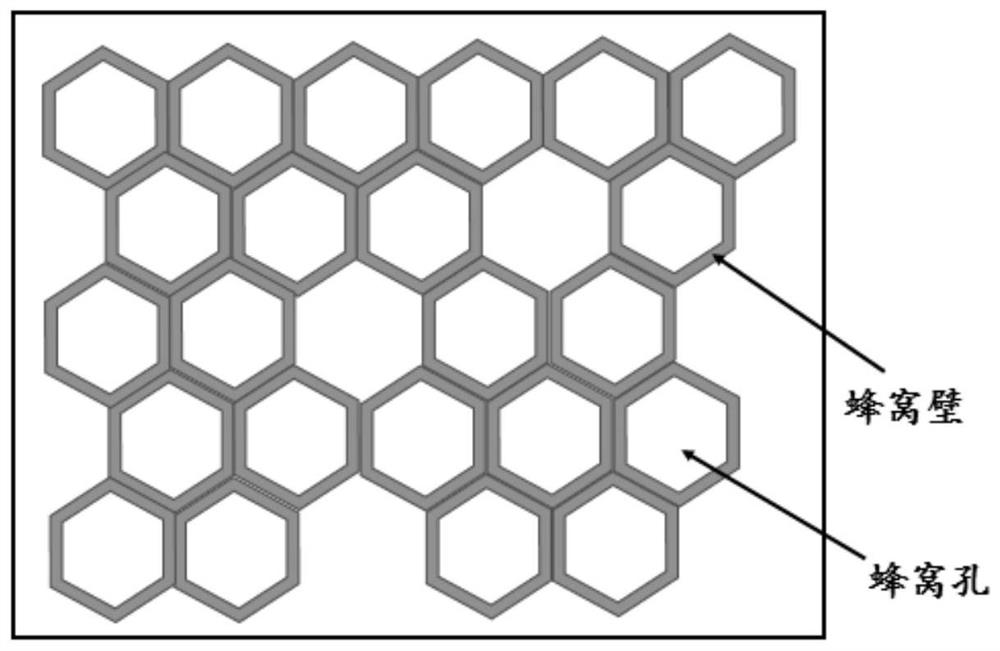

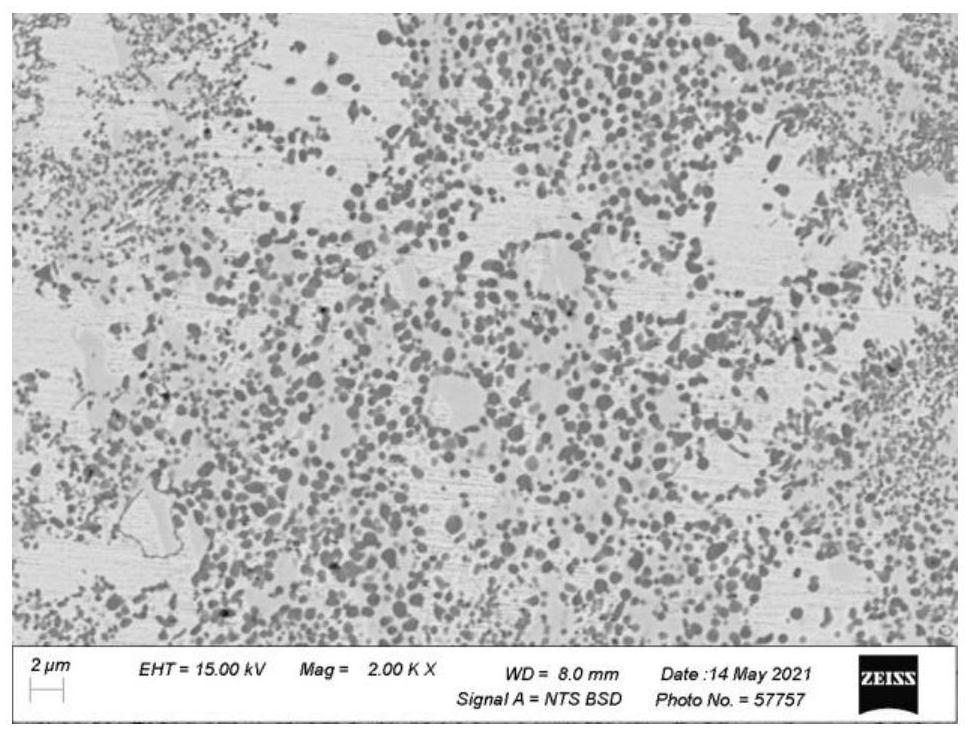

[0025] This example relates to a method for preparing a high-chromium cast iron-based honeycomb macro-heterogeneous composite material reinforced by in-situ self-generated ZTA ceramic particles. The specific steps are as follows:

[0026] (1) Dissolve aluminum nitrate nonahydrate and zirconium oxynitrate hydrate in deionized water, then drop in citric acid to obtain a mixed solution, wherein the molar ratio of aluminum nitrate nonahydrate, zirconium oxynitrate hydrate, and citric acid is 1: 0.1:0.1.

[0027] (2) Use nitric acid and ammonia water to adjust the pH value of the mixed solution to 2, add 1.0% (mol fraction) ethylene glycol as a dispersant to the mixed solution, stir well, put it in a constant temperature water bath and heat it for 8 hours to obtain a certain viscosity transparent sol.

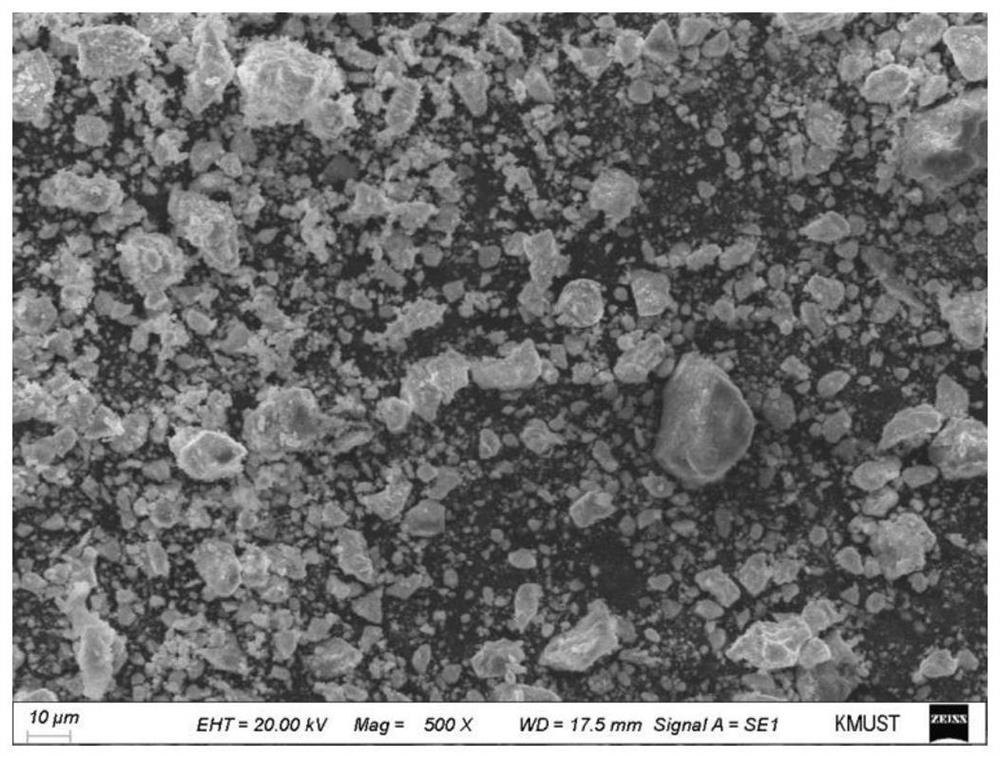

[0028] (3) Add high-chromium cast iron powder with a particle size of 50 μm to the sol, the molar ratio of high-chromium cast iron powder to transparent sol is 0.5:1, stir rapidly ...

Embodiment 2

[0032] This embodiment relates to a method for preparing a high-manganese steel-based honeycomb macro-heterogeneous composite material reinforced by in-situ self-generated ZTA ceramic particles. The specific steps are as follows:

[0033] (1) Dissolve aluminum nitrate nonahydrate and zirconium oxynitrate hydrate in deionized water, then drop in citric acid to obtain a mixed solution, wherein the molar ratio of aluminum nitrate nonahydrate, zirconium oxynitrate hydrate, and citric acid is 1: 0.2:0.15.

[0034] (2) Use nitric acid and ammonia water to adjust the pH value of the mixed solution to 1, add 0.5% (mol fraction) ethylene glycol as a dispersant to the mixed solution, stir well, put it in a constant temperature water bath and heat it for 6 hours to obtain a certain viscosity transparent sol.

[0035] (3) Add high manganese steel powder with a particle size of 20 μm to the sol, the molar ratio of high manganese steel powder to transparent sol is 0.3:1, stir rapidly for 0...

Embodiment 3

[0039] This embodiment relates to a method for preparing an alloy steel-based honeycomb-shaped macroscopic heterogeneous composite material reinforced by in-situ self-generated ZTA ceramic particles. The specific steps are as follows:

[0040] (1) Dissolve aluminum nitrate nonahydrate and zirconium oxynitrate hydrate in deionized water, then drop in citric acid to obtain a mixed solution, wherein the molar ratio of aluminum nitrate nonahydrate, zirconium oxynitrate hydrate, and citric acid is 1: 0.3:0.2.

[0041] (2) Use nitric acid and ammonia water to adjust the pH value of the mixed solution to 3, add 2.0% (mol fraction) of ethylene glycol as a dispersant to the mixed solution, stir well, put it in a constant temperature water bath and heat it for 10 hours to obtain a certain viscosity transparent sol.

[0042] (3) Add alloy steel powder with a particle size of 100 μm to the sol, the molar ratio of alloy steel powder to transparent sol is 0.6:1, stir rapidly for 0.4h until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com