ABO3 type double perovskite LaCoyNi1-yO3 nanorod electro-catalytic material and preparation method thereof

An electrocatalytic material, double perovskite technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of inability to realize large-scale application, low catalyst yield, poor selectivity, etc., achieve excellent performance and simple preparation process , Repeated tests with good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

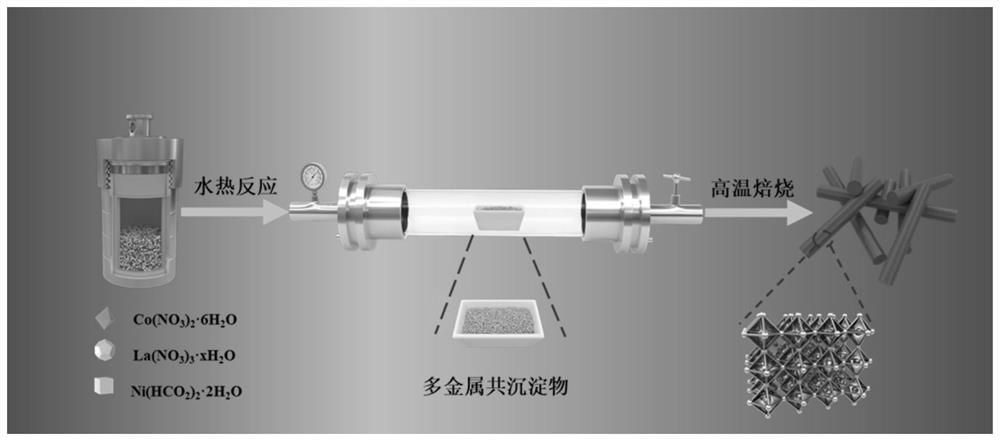

Method used

Image

Examples

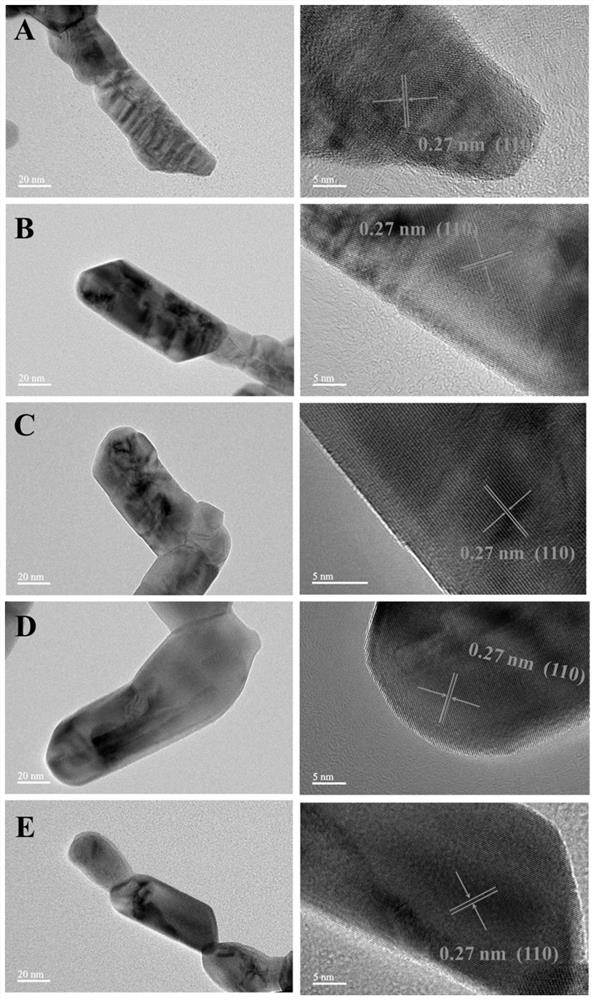

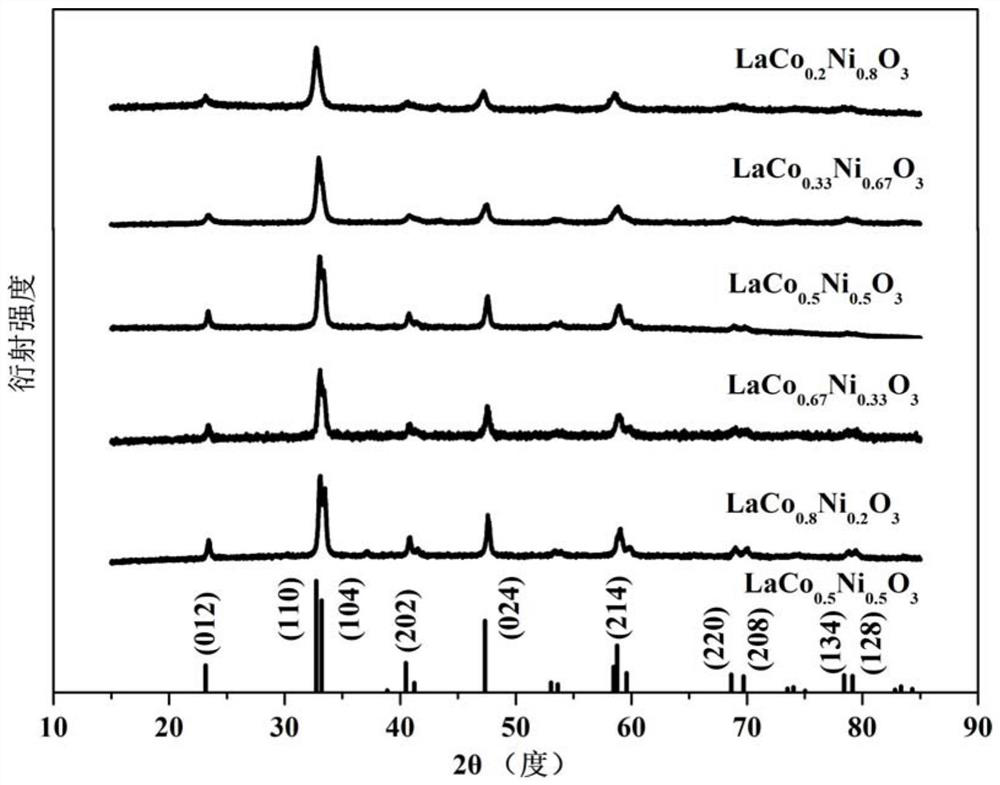

Embodiment 1

[0049] Under stirring, 48.7mg of La(NO 3 ) 3 ·xH 2 O, 8.73mg of Co(NO 3 ) 2 ·6H 2 O and 22.17mg of Ni(HCO 2 ) 2 2H 2 O was dissolved in 27 mL of deionized water to obtain a clear and transparent solution. Subsequently, 3 mL of 1 mol / L KOH was added to obtain a cloudy dispersion, and the mixed solution was reacted at 180° C. for 10 h to form a suspension. Then, the above liquid was filtered, washed with water / ethanol, and dried at 70°C. Subsequently, the above-mentioned powders were calcined at a high temperature for 2 h at 250 °C in an argon atmosphere (wherein, the heating rate was 5 °C min -1 ), at 5°C min -1 The heating rate was increased to 650°C and kept for 5h. After several acid washes, LaCo 0.2 Ni 0.8 o 3 Nano stave. It is tested by experiments that LaCo 0.2 Ni 0.8 o 3 The nanorods have nitrogen electroreduction performance, within a certain overpotential range, the highest yield of ammonia and the highest Faradaic efficiency of 8.00 μg h -1 mg -1 ...

Embodiment 2

[0051] Under stirring, 48.7mg of La(NO 3 ) 3 ·xH 2 O, 14.55mg of Co(NO 3 ) 2 ·6H 2 O and 18.48mg of Ni(HCO 2 ) 2 2H 2 O was dissolved in 27 mL of deionized water to obtain a clear and transparent solution. Subsequently, 3 mL of 1 mol / L KOH was added to obtain a cloudy dispersion, and the mixed solution was reacted at 180° C. for 10 h to form a suspension. Then, the above liquid was filtered, washed with water / ethanol, and heated at 70 °C. Subsequently, the above-mentioned powders were calcined at a high temperature for 2 h at 250 °C in an argon atmosphere (wherein, the heating rate was 5 °C min -1 ), continue at 5°C min -1 The heating rate was increased to 650°C and kept for 5h. After several acid washes, LaCo 0.33 Ni 0.67 o 3 Nano stave. It is tested by experiments that LaCo 0.33 Ni 0.67 o 3 The nanorods have nitrogen electroreduction properties, and within a certain overpotential range, the highest yield of ammonia and the highest Faradaic efficiency are 8....

Embodiment 3

[0053] Under stirring, 48.7mg of La(NO 3 ) 3 ·xH 2 O, 21.83mg of Co(NO 3 ) 2 ·6H 2 O and 13.86mg of Ni(HCO 2 ) 2 2H 2 O was dissolved in 27 mL of deionized water to obtain a clear and transparent solution. Subsequently, 3 mL of 1 mol / L KOH was added to obtain a cloudy dispersion, and the mixed solution was reacted at 180° C. for 10 h to form a suspension. Then, the above liquid was filtered, washed with water / ethanol, and dried at 70°C. Subsequently, the above-mentioned powders were calcined at a high temperature for 2 h at 250 °C in an argon atmosphere (wherein, the heating rate was 5 °C min -1 ), continue at 5°C min -1 The heating rate was increased to 650°C and kept for 5h. After several acid washes, LaCo 0.5 Ni 0.5 o 3 Nano stave. It is tested by experiments that LaCo 0.5 Ni 0.5 o 3 The nanorods have nitrogen electroreduction properties, and within a certain overpotential range, the highest yield of ammonia and the highest Faradaic efficiency are 13.48 μg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Faraday efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com