A kind of cerium-phosphorus complex flame retardant, cerium-phosphorus complex flame retardant polycarbonate composite material and their preparation method

A technology of flame-retardant polycarbonate and composite materials, applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of discounting the practical performance and application fields of polymer materials, and destroying polymerization The physical and mechanical properties of the material, increasing the workload of compound selection and addition, etc., to achieve the effect of inhibiting the formation of molten droplets and the overflow of toxic fumes, the preparation and processing methods are simple and easy, and the effect of avoiding secondary fires and secondary injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

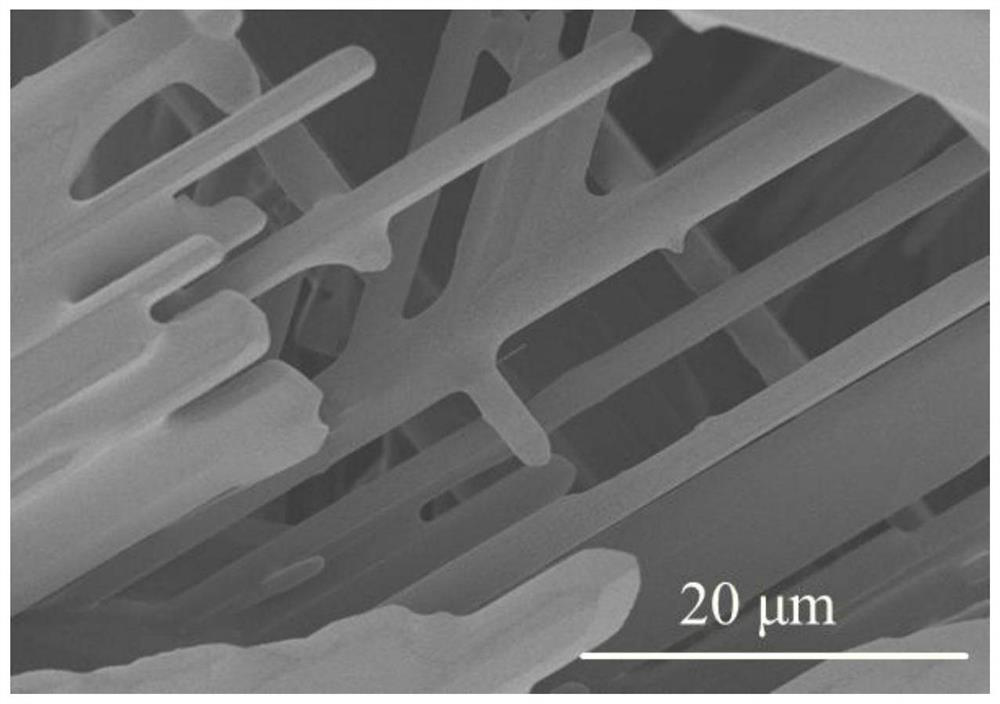

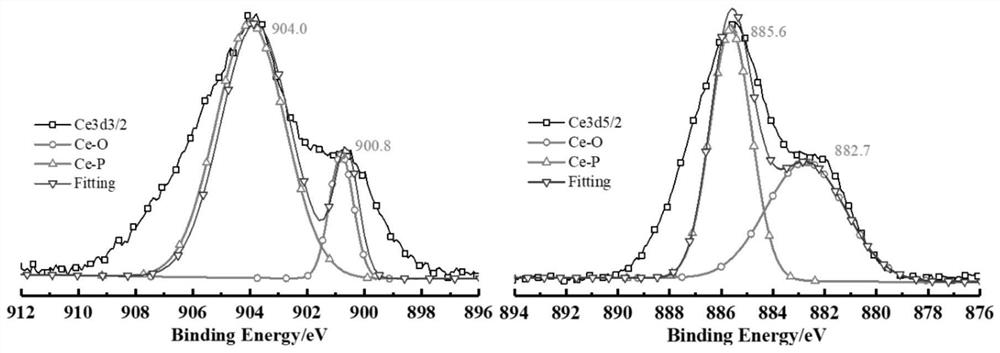

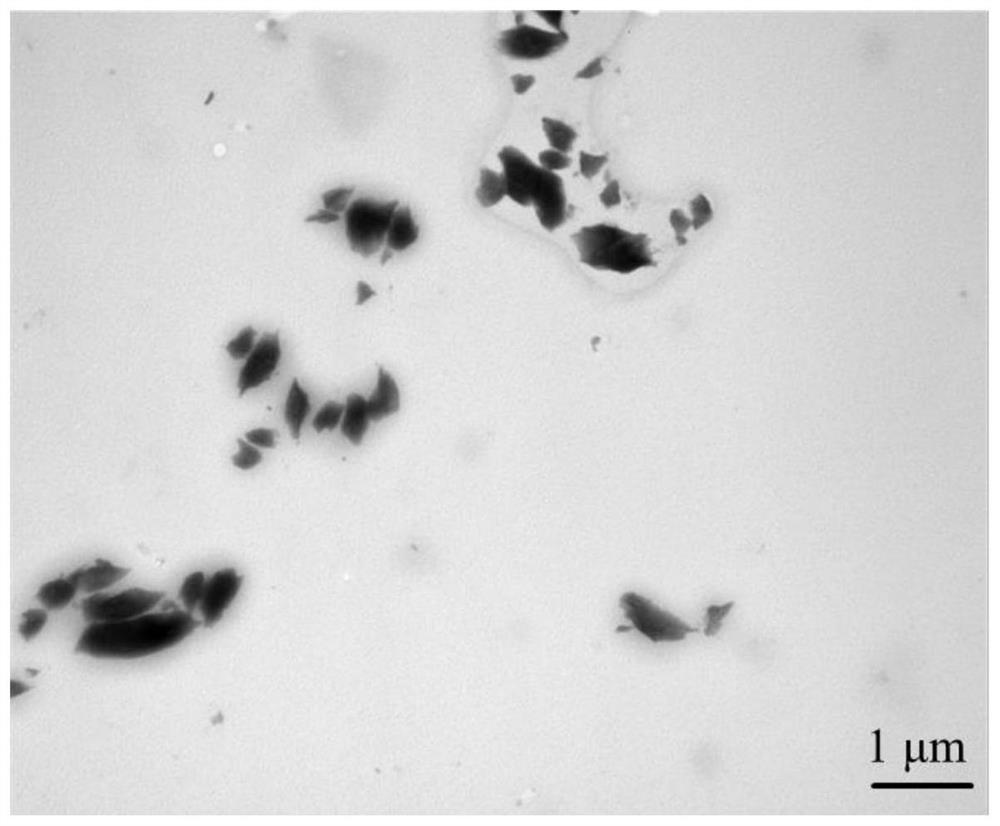

[0056]The preparation method of the cerium-phosphorus compound flame retardant in this embodiment includes the following steps:

[0057](1) Weigh 0.025 mol of DOPO in 200 ml of DMF, stirred at room temperature for 60 min to give a solution A; weigh 0.050 mol of nitrate hydrate in 200 ml of deionized water, stirred at room temperature for 15 min, obtained solution B, used Nitrate hydrate, the purity of DOPO is ≥97%, and the purity of DMF is ≥99%, and the deionized water is ultrapure water in electrical conductivity ≥18mΩ;

[0058](2) The solution B was added dropwise to the stirred solution A, and the mixture was continued at normal temperature for 25 min to prepare a mixed solution;

[0059](3) The mixed solution was transferred to a hydrothermal reaction kettle having a polytetrafluoroethylene liner, and then the reaction kettle was carried out in a blower oven for hydrothermal reaction, and the reaction temperature was 120 ° C, the reaction time was 24 h;

[0060](4) After the product was nat...

Embodiment 2

[0062]The difference from Embodiments is only that 0.025 mol of nitrate hydrate is integrated into 200 ml of deionized water, i.e., DOPO and nitrate hydrate, i.e., 1: 1.

Embodiment 3

[0064]The difference from Example 1 is only in that, in Example 3, 0.075 mol of nitrate hydrate was weighed in 200 ml of deionized water, i.e., DOPO and nitrate hydrate of the hydrate of 1: 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com