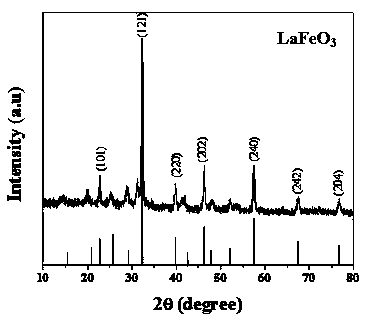

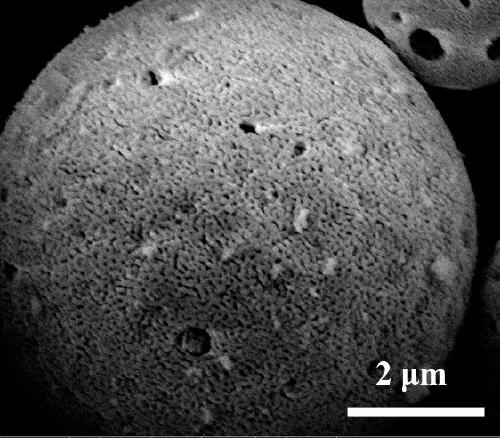

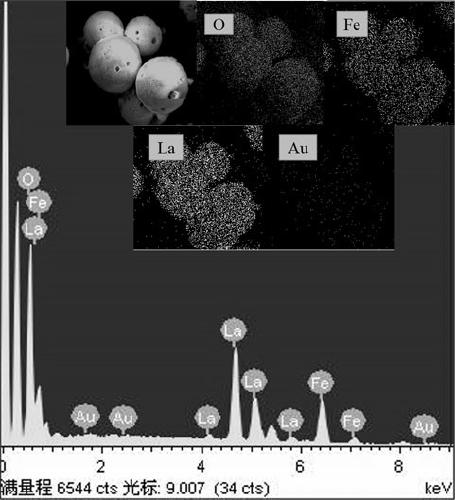

Preparation method of Au-LaFeO3 nanocomposite material

A nanocomposite material and hydration technology, which is applied in the field of preparation of Au-LaFeO3 nanocomposite materials, can solve the problems of poor material selectivity, restricted detection performance, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Weigh a certain amount of hydrated lanthanum nitrate, hydrated ferric nitrate and citric acid and dissolve them in 40 mL of deionized water. The concentration of acid is 0.1 mol / L, and the mol ratio of controlling hydrated lanthanum nitrate and hydrated ferric nitrate is 1:1, and the mol ratio of controlling hydrated lanthanum nitrate and citric acid is 1:5;

[0018] (2) Transfer the mixed solution obtained in step (1) to a magnetic heating stirrer and heat it in a water bath at 40 °C for 30 min and stir until the drug is completely dissolved. After the above solution is naturally cooled to room temperature, transfer it to a polystyrene liner. In the hydrothermal reaction kettle of vinyl fluoride, the hydrothermal reaction was carried out at 170 °C for 9 h, and then the product after the hydrothermal reaction was separated from the solid and liquid by a centrifuge, and the obtained solid product was subjected to multi-treatment with deionized water and ethanol. Afte...

Embodiment 2

[0022] (1) Weigh a certain amount of hydrated lanthanum nitrate, hydrated ferric nitrate and citric acid and dissolve them in 40 mL of deionized water. The concentration of acid is 0.15 mol / L, and the mol ratio of controlling hydrated lanthanum nitrate and hydrated ferric nitrate is 1:1, and the mol ratio of controlling hydrated lanthanum nitrate and citric acid is 1:5;

[0023] (2) Transfer the mixed solution obtained in step (1) to a magnetic heating stirrer and heat it in a water bath at 50 °C for 30 min and stir until the drug is completely dissolved. After the above solution is naturally cooled to room temperature, transfer it to a polystyrene liner. In the hydrothermal reaction kettle of vinyl fluoride, the hydrothermal reaction was carried out at 180 °C for 9 h, and then the product after the hydrothermal reaction was separated from the solid and liquid by a centrifuge, and the obtained solid product was subjected to multi-treatment with deionized water and ethanol. Aft...

Embodiment 3

[0027] (1) Weigh a certain amount of hydrated lanthanum nitrate, hydrated ferric nitrate and citric acid and dissolve them in 40 mL of deionized water. The concentration of acid is 0.3 mol / L, and the mol ratio of controlling hydrated lanthanum nitrate and hydrated ferric nitrate is 1:1, and the mol ratio of controlling hydrated lanthanum nitrate and citric acid is 1:6;

[0028] (2) Transfer the mixed solution obtained in step (1) to a magnetic heating stirrer and heat it in a water bath at 50 °C for 30 min and stir until the drug is completely dissolved. After the above solution is naturally cooled to room temperature, transfer it to a polystyrene liner. In the hydrothermal reaction kettle of vinyl fluoride, the hydrothermal reaction was carried out at 180 °C for 9 h, and then the product after the hydrothermal reaction was separated from the solid and liquid by a centrifuge, and the obtained solid product was subjected to multi-treatment with deionized water and ethanol. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com