Electrocatalytic bifunctional material with few layers of tungsten disulfide anchored on surface of cobalt-nitrogen-doped carbon-based polyhedron and preparation method of electrocatalytic bifunctional material

A bifunctional material, tungsten disulfide technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of restricting large-scale industrial application, high cost and scarcity of the earth, so as to enrich the active sites of metals and optimize the active sites Point and conductivity, the effect of shortening the diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing an electrocatalytic bifunctional material anchored on the surface of a cobalt-nitrogen-doped carbon-based polyhedron with few layers of tungsten disulfide, comprising the following steps:

[0044] Step 1. Weigh 0.58206g-2.9103g of cobalt nitrate hexahydrate and add it to 10-30ml of methanol to prepare solution A for later use;

[0045] Step 2. Weigh a certain amount of 2-methylimidazole and add it to 10-30ml of methanol to prepare solution B for later use; the molar ratio of cobalt ions in step 1 to 2-methylimidazole in step 2 is 1:( 3~8).

[0046] Step 3. Pour solution B obtained in step 2 into solution A obtained in step 1, then immediately add 0.01g to 0.4g of ammonium tetrathiotungstate, and stir at room temperature for 5 to 25 hours;

[0047] Step 4: Collect the product obtained in Step 3 by centrifugation. The speed of the centrifuge is 8000-10000 rpm. The upper solution is discarded to obtain the lower precipitate. The lower precipitate is...

Embodiment 1

[0050] 1) Weigh 0.58206g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) add in 15mL methanol and be mixed with solution A;

[0051] 2) Weigh 0.6169g of 2-methylimidazole and add it into 15mL of methanol to prepare solution B;

[0052] 3) Pour solution B into solution A, stir evenly to form uniform dark blue solution C;

[0053] 4) Add 0.05g ammonium tetrathiotungstate ((NH 4 ) 2 WS 4 ), vigorously stirred at room temperature for 24h, and the stirring rate was 500rpm. Centrifuge the obtained product at 8000 rpm for 5 min, discard the upper layer solution to obtain the lower layer precipitate, wash the lower layer precipitate 5 times with methanol to remove residual unreacted substances, and then vacuum dry at 50 ° C for 24 h to obtain a brown powder, which is WS 4 2- -ZIF-67;

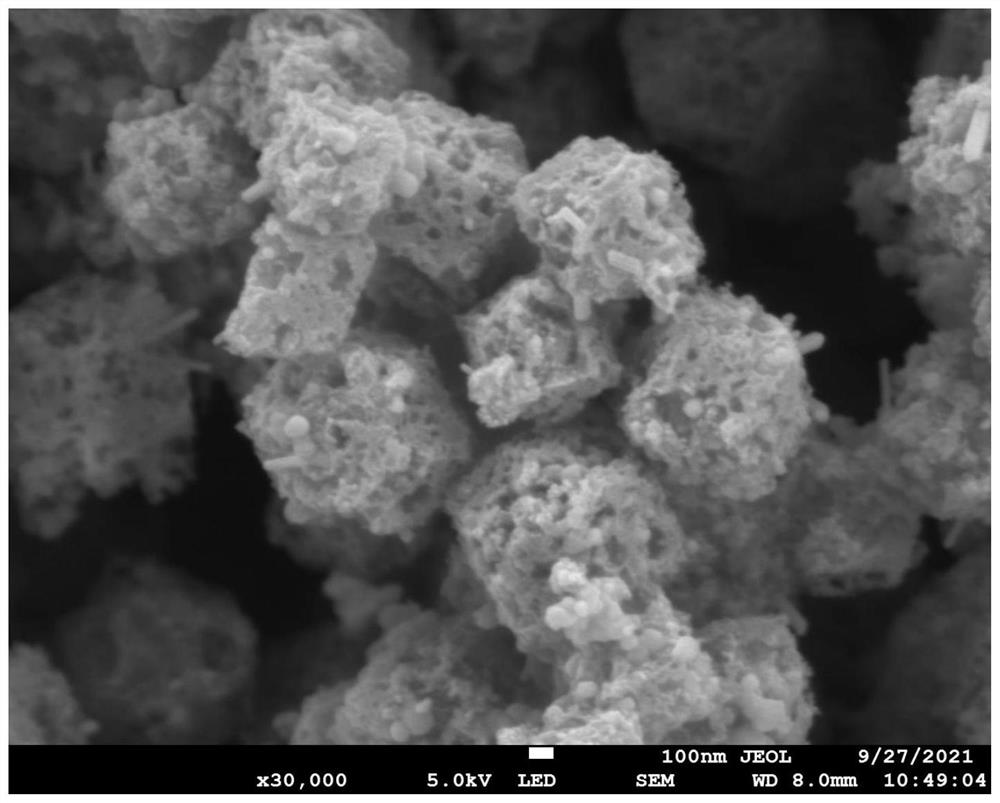

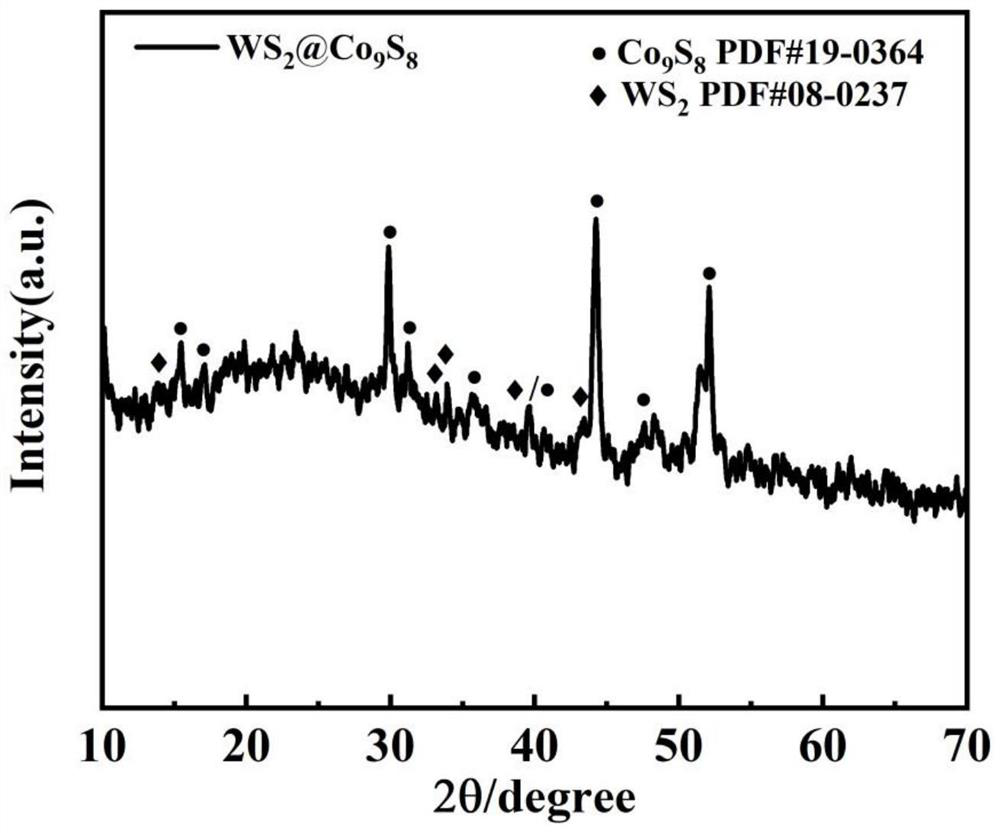

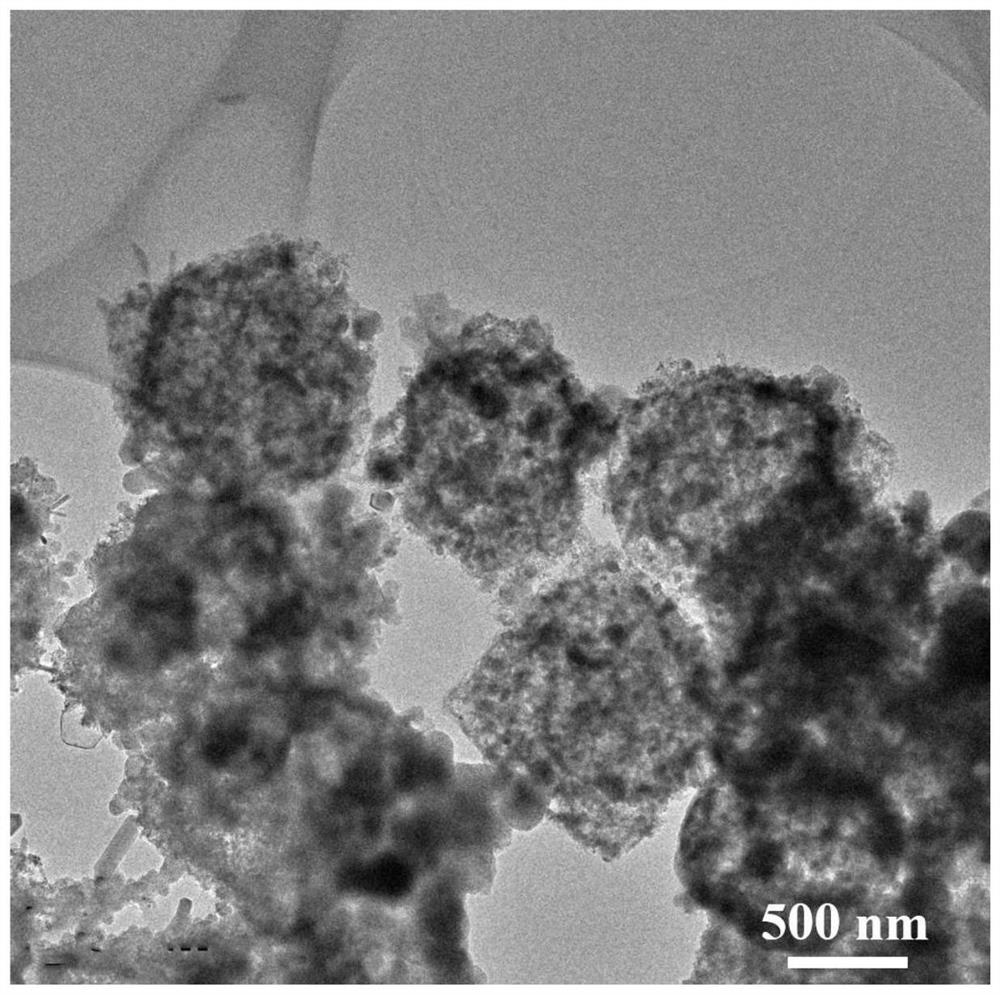

[0054] 5) step 4) gained brown powder is placed in tube furnace, under N 2 Under the protection of atmosphere, heat up to 400°C at a heating rate of 5°C / min, hold for 2h, N 2 The working pre...

Embodiment 2

[0066] 1) Weigh 0.58206g of cobalt nitrate hexahydrate and add it into 15mL of methanol to prepare solution A;

[0067] 2) Weigh 0.6169g of 2-methylimidazole and add it into 15mL of methanol to prepare solution B;

[0068] 3) Pour solution B into solution A, stir evenly to form uniform dark blue solution C;

[0069] 4) Add 0.1 g of ammonium tetrathiotungstate to the dark blue solution C, stir vigorously at room temperature for 24 hours, and the stirring speed is 500 rpm. Centrifuge the obtained product at 8000 rpm for 5 min, discard the upper layer solution to obtain the lower layer precipitate, wash the lower layer precipitate 5 times with methanol to remove residual unreacted substances, and then vacuum dry at 50 ° C for 24 h to obtain a brown powder, which is WS 4 2- -ZIF-67;

[0070] 5) step 4) gained brown powder is placed in tube furnace, under N 2 Under the protection of atmosphere, heat up to 400°C at a heating rate of 5°C / min, hold for 2h, N 2 The working pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com