Preparation method for hollow silicate

A silicate and hollow technology, applied in the field of silicates, can solve the problems of insufficient research on synthesis methods and preparation condition parameters, and no silicates have been found, and achieve the effects of simple post-processing, wide versatility, and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

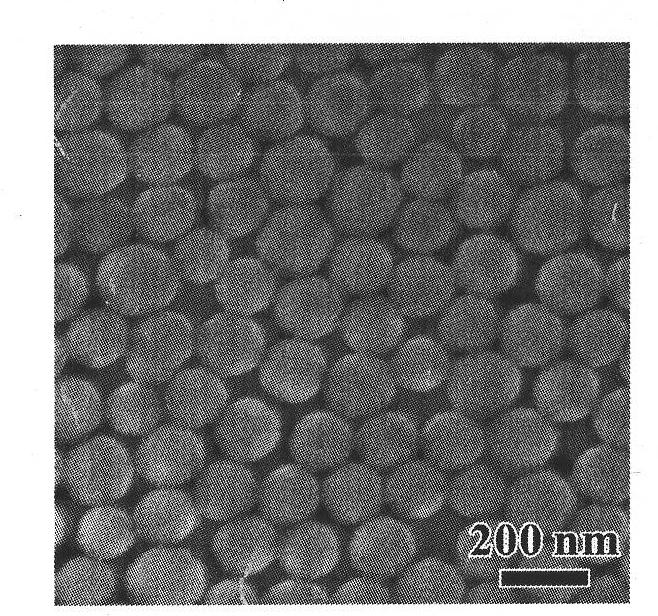

[0024] 1) Synthesis of silica nanospheres: 1.6mL tetraethyl orthosilicate, 1.6mL water and 1.6mL ammonia water were added to 27.2mL ethanol, and after reacting at room temperature for 6 hours, the obtained product was washed 6 times with ethanol and water respectively, Get silica nanospheres (see figure 1 ).

[0025] 2) Add 10mL water and 5mL ethanol to the 25mL polytetrafluoroethylene lining, and then add 25mg silicon dioxide, 0.675g urea, 0g dihydrate-2-hydroxy-5-sulfobenzoic acid, 0.073g hexahydrate Nickel nitrate was added. The polytetrafluoroethylene lining was placed in the reaction kettle, and the temperature was kept at 190°C for 36h.

[0026] 3) After the reaction is completed and cooled to room temperature, the obtained solid product is washed three times with water and ethanol respectively to obtain the target product.

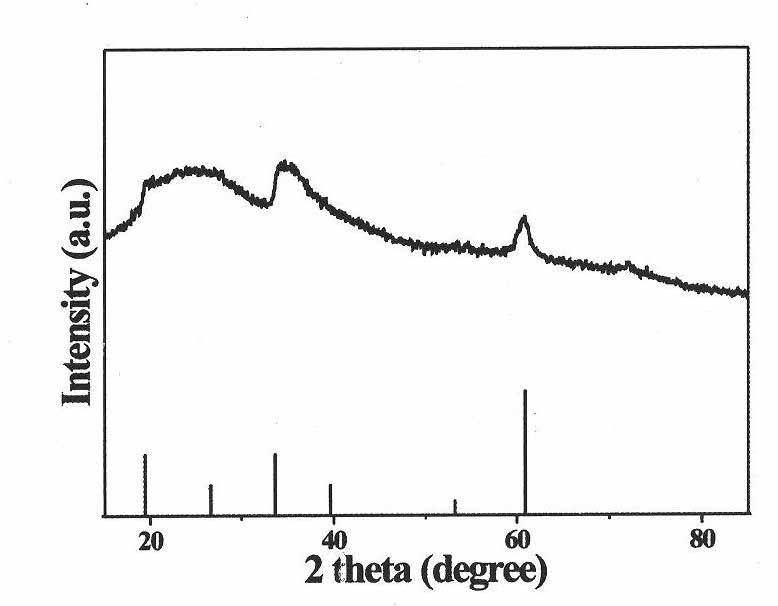

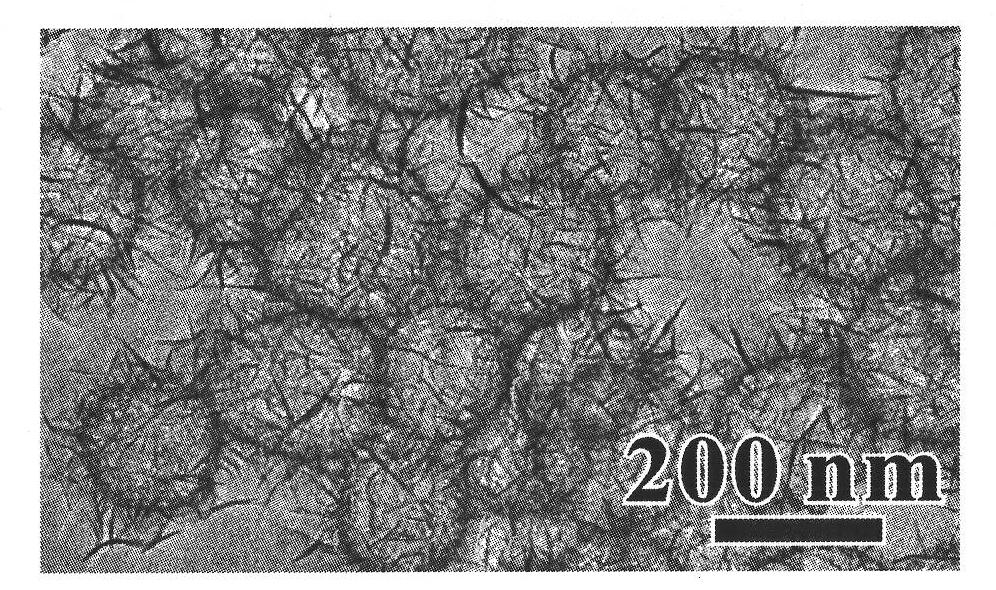

[0027] The composition and morphology of the product were systematically studied by X-ray powder diffraction and transmission electron microscop...

Embodiment 2

[0029] 1) Synthesis of silica nanospheres: 6.4mL tetraethyl orthosilicate, 2.4mL water and 3.2mL ammonia water were added to 54.4mL ethanol, and after reacting at room temperature for 3h, the obtained product was washed twice with ethanol and water respectively, That is, silica nanospheres are obtained.

[0030] 2) Add 10mL water and 5mL ethanol to the 25mL polytetrafluoroethylene lining, and then add 35mg silicon dioxide, 0.675g urea, 0g dihydrate-2-hydroxy-5-sulfobenzoic acid, 0.073g hexahydrate Nickel nitrate was added. The polytetrafluoroethylene lining was placed in the reaction kettle, and the temperature was kept at 190°C for 36h.

[0031] 3) After the reaction is completed and cooled to room temperature, the obtained solid product is washed with water and ethanol four times respectively to obtain the target product.

Embodiment 3

[0033] 1) Synthesis of silica nanospheres: 3.2mL tetraethyl orthosilicate, 3.2mL water and 6.4mL ammonia water were added to 108.8mL ethanol, and after reacting at room temperature for 9 hours, the obtained product was washed 10 times with ethanol and water respectively, That is, silica nanospheres are obtained.

[0034] 2) Add 10mL of water and 5mL of ethanol to 25mL of polytetrafluoroethylene lining, and then add 50mg of silicon dioxide, 0.675g of urea, 0g of dihydrate-2-hydroxy-5-sulfobenzoic acid, and 0.073g of hexahydrate Nickel nitrate was added. The polytetrafluoroethylene lining was placed in the reaction kettle, and the temperature was kept at 190°C for 36h.

[0035] 3) After the reaction is completed and cooled to room temperature, the obtained solid product is washed with water and ethanol for 6 times respectively to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com