Petal-shaped manganese-cerium composite oxide denitration catalyst and preparation method thereof

The technology of composite oxide and denitration catalyst is applied in the field of petal-shaped manganese-cerium composite oxide denitration catalyst and its preparation, which can solve the problems such as inability to meet emission requirements and achieve the effect of promoting adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The manganese dioxide of the catalyzer that makes in embodiment 1, the mol ratio of ceria is 1:1, and its preparation method comprises the following steps:

[0029] (1) 0.4g manganese nitrate tetrahydrate, 0.4g cerium nitrate hexahydrate, 1g potassium permanganate and 36ml deionized water are mixed under stirring, wherein the stirring speed is at 300rpm / min, and the stirring time is 1.5h, and then The mixed solution was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 140°C for 12 hours;

[0030] (2) After cooling down to obtain a suspension, wash the suspension with deionized water for about 5 to 10 times, then centrifugally dry the suspension for 12 hours;

[0031] (3) Then heat up to 500°C in air atmosphere and keep for 6h.

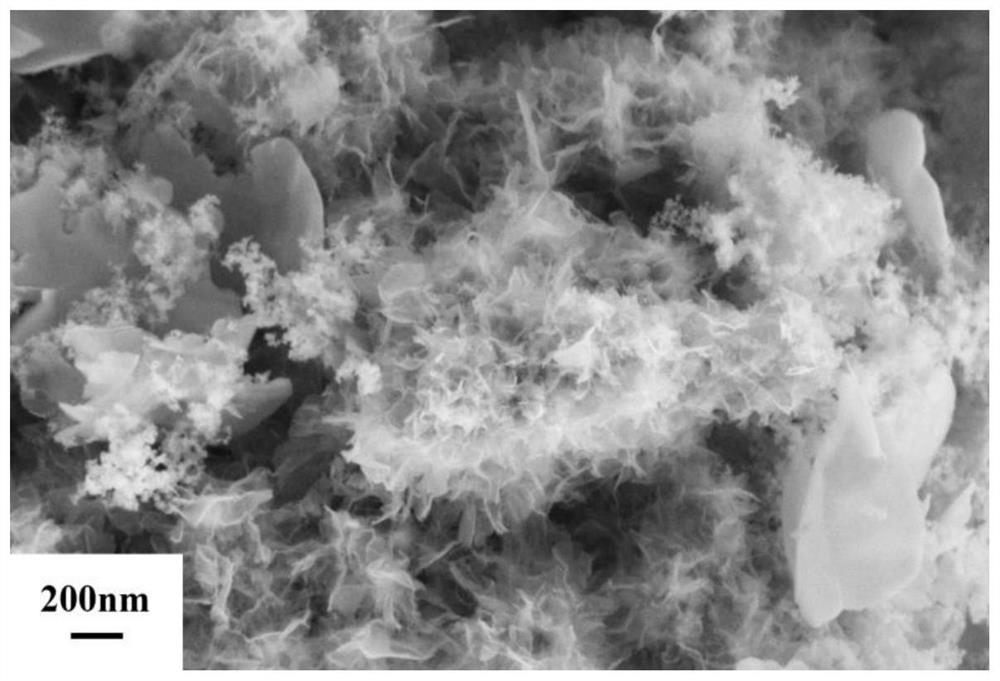

[0032] The SEM figure of the catalyst that embodiment 1 makes is as figure 1 shown, from figure 1 It can be seen that the catalyst presents a petal-like structure after calcination.

Embodiment 2

[0034] The manganese dioxide of the catalyzer that makes in embodiment 2, the mol ratio of ceria is 5:1, and its preparation method comprises the following steps:

[0035] (1) 0.63g manganese nitrate tetrahydrate, 0.17g cerium nitrate hexahydrate, 1g potassium permanganate and 36ml deionized water are mixed under stirring, wherein the stirring speed is 300rpm / min, and the stirring time is 1.5h, and then The mixed solution was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 140°C for 12 hours;

[0036] (2) After cooling down to obtain a suspension, wash the suspension with deionized water for about 5 to 10 times, then centrifugally dry the suspension for 12 hours;

[0037] (3) Then heat up to 500°C in air atmosphere and keep for 6h.

Embodiment 3

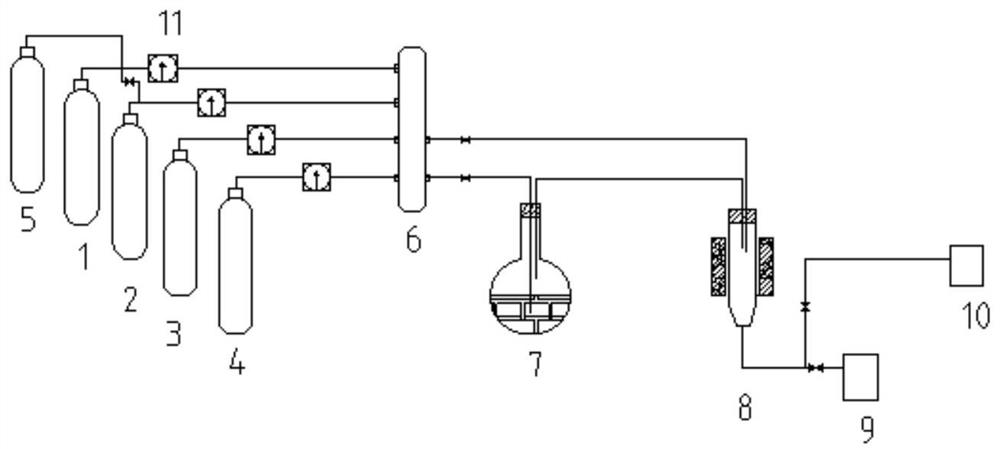

[0039] Pack the catalysts prepared in Examples 1 and 2 into self-made quartz reaction tubes, feed mixed gas, and adjust the GHSV to 100,000 to 130,000 hours -1 During the test, the temperature was raised to test its activity; at each temperature point, a flue gas analyzer was used to detect its NO concentration, and a laughing gas detector was used to detect its N 2 O production.

[0040] The test system structure is as figure 2 shown.

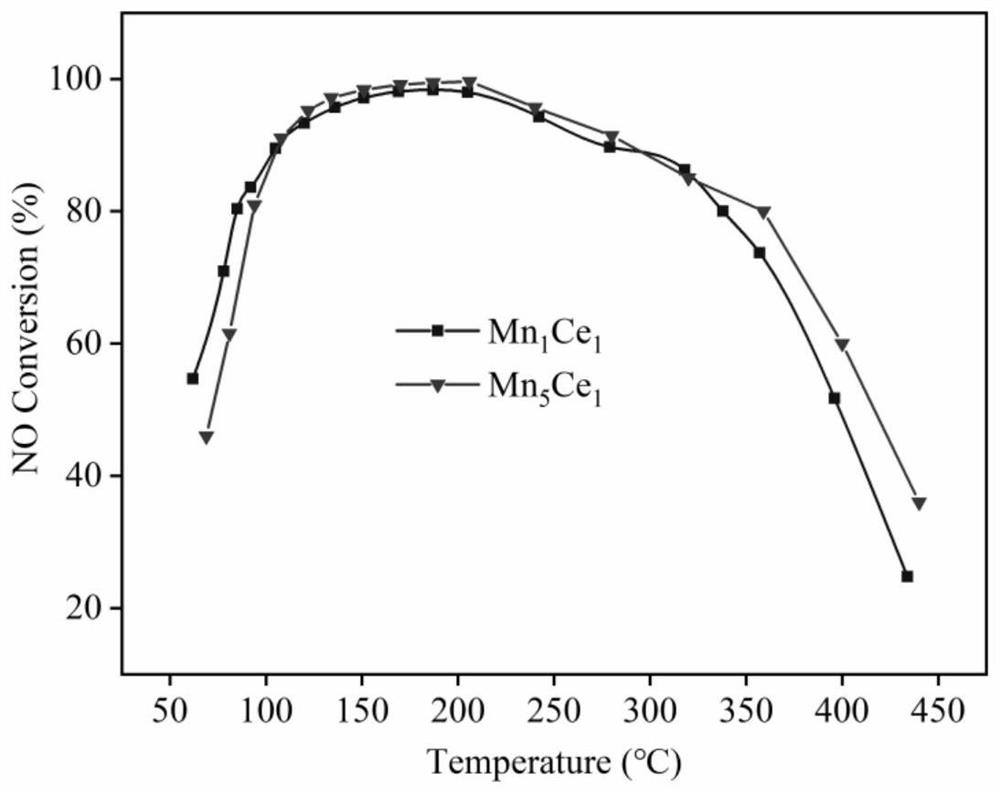

[0041] image 3 is the NO catalytic activity of different ratios of manganese-cerium composite oxides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com