Nitrogen-enriched hollow hybrid carbon catalytic material as well as preparation method and application thereof

A carbon catalysis and enrichment technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of low nitrogen introduction, underdeveloped pore structure, and few applications, and achieve high nitrogen content. , Small environmental pollution, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A kind of method for preparing monodisperse Zn-ZIF, specifically finish according to the following steps:

[0080] Zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) and manganese nitrate (Mn(NO 3 ) 2 ) was dissolved in methanol to form a homogeneous metal solution; finally, the metal solution was quickly poured into a methanol solution containing 2-methylimidazole under stirring; left to react at room temperature for 24 hours, filtered, washed twice with water, and washed with methanol 3 times, and then dried at a temperature of 100°C for 8 hours to obtain Zn-ZIF;

[0081] Zn(NO 3 ) 2 ·6H 2 The concentration of O is 100mmol / L;

[0082] Mn(NO 3 ) 2 The concentration is 0mmol / L;

[0083] The concentration of 2-methylimidazole in the methanol solution of 2-methylimidazole described in the step is 500mmol / L;

[0084] The volume ratio of the metal solution described in the step to the methanol solution of 2-methylimidazole is 1:1.

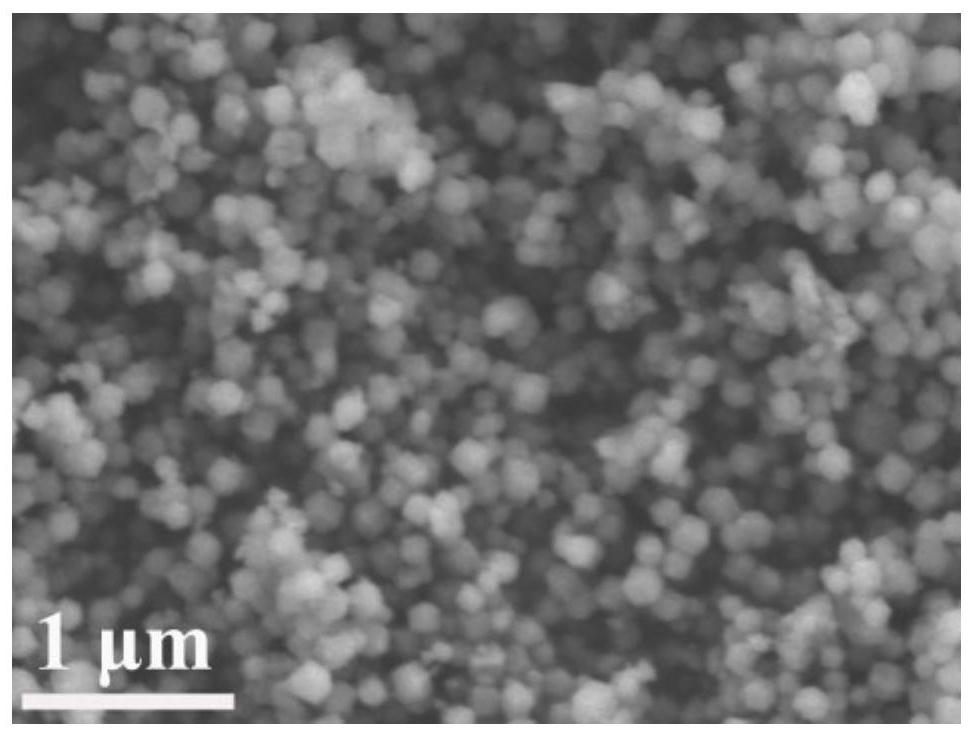

[0085] figure 1 For the SEM fig...

Embodiment 2

[0087] A kind of method for preparing monodisperse Mn-Zn-ZIF, specifically finish according to the following steps:

[0088] Zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) and manganese nitrate (Mn(NO 3 ) 2 ) was dissolved in methanol to form a homogeneous metal solution; finally, the metal solution was quickly poured into a methanol solution containing 2-methylimidazole under stirring; left to react at room temperature for 24 hours, filtered, washed twice with water, and washed with methanol 3 times, and then dried at a temperature of 100°C for 8 hours to obtain Mn-Zn-ZIF;

[0089] Zn(NO 3 ) 2 ·6H 2 The concentration of O is 100mmol / L;

[0090] Mn(NO 3 ) 2The concentration is 10mmol / L;

[0091] The concentration of 2-methylimidazole in the methanol solution of 2-methylimidazole described in the step is 500mmol / L;

[0092] The volume ratio of the metal solution described in the step to the methanol solution of 2-methylimidazole is 1:1.

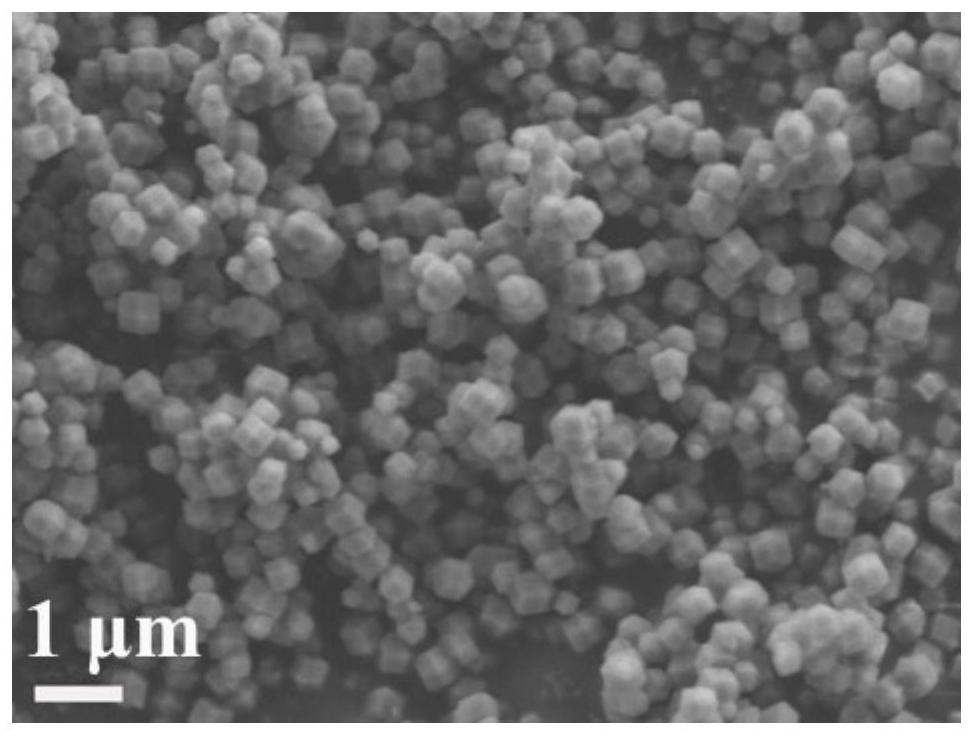

[0093] figure 2 For the ...

Embodiment 3

[0095] A kind of method for preparing monodisperse Mn-Zn-ZIF, specifically finish according to the following steps:

[0096] Zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) and manganese nitrate (Mn(NO 3 ) 2 ) was dissolved in methanol to form a homogeneous metal solution; finally, the metal solution was quickly poured into a methanol solution containing 2-methylimidazole under stirring; left to react at room temperature for 24 hours, filtered, washed twice with water, and washed with methanol 3 times, and then dried at a temperature of 100°C for 8 hours to obtain Mn-Zn-ZIF;

[0097] Zn(NO 3 ) 2 ·6H 2 The concentration of O is 100mmol / L;

[0098] Mn(NO 3 ) 2 The concentration is 20mmol / L;

[0099] The concentration of 2-methylimidazole in the methanol solution of 2-methylimidazole described in the step is 500mmol / L;

[0100] The volume ratio of the metal solution described in the step to the methanol solution of 2-methylimidazole is 1:1.

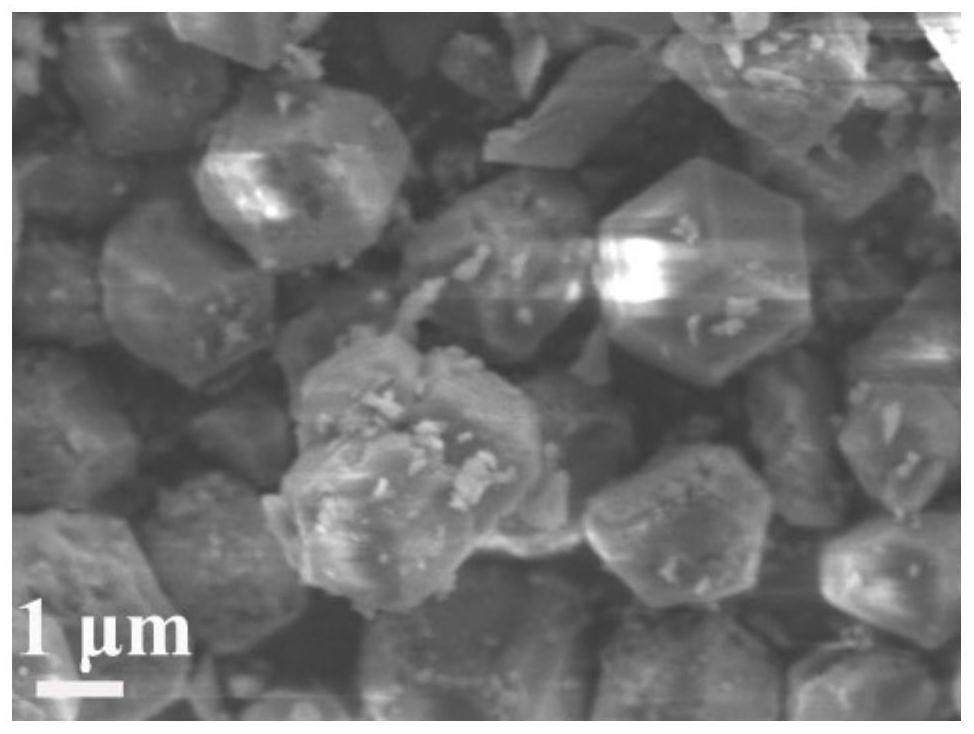

[0101] image 3 For the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com