Sweet corn fermented wine and preparation method thereof

A technology of sweet corn and fermented wine, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of loss of nutrients, insufficient flavor of fermented wine products, and insufficient flavor of product characteristics, and achieve the effect of improving nutritional value and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

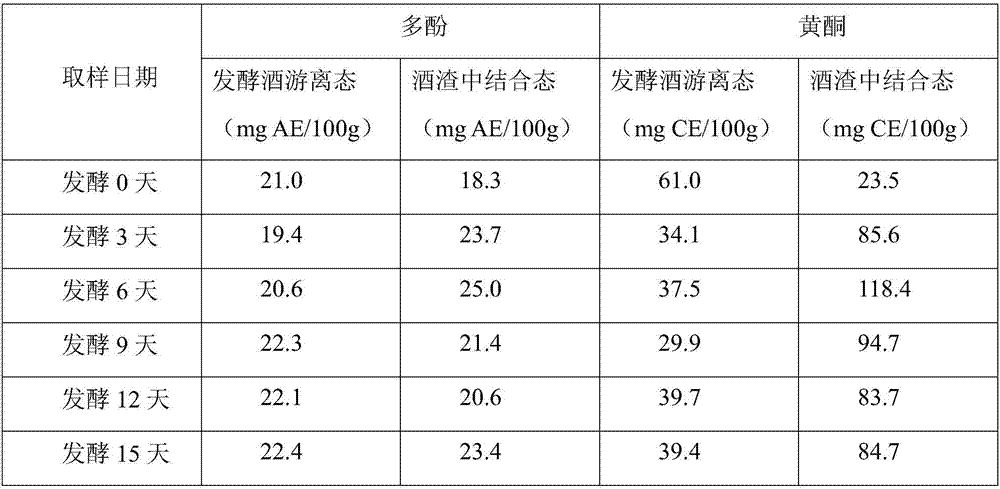

Embodiment 1

[0039] 1. Sweet corn pretreatment: Screen high-quality sweet corn, peel and wash, and then thresh. The corn kernels were collected and packed in fresh-keeping bags, and stored in a -80°C refrigerator for later use.

[0040] 2. Homogenizing corn kernels: mix 2 kg of sweet corn kernels with distilled water at a material weight ratio of 1:1, beat with a mixer, and transfer to a fermentation tank. The total volume of the obtained corn slurry accounts for 80% of the volume of the fermentation tank . No need to add pectinase and cellulase.

[0041] 3. Adjustment of sugar content: Add white granulated sugar and adjust the sugar content to 150g / L.

[0042] 4. Fermentation strain inoculation: drop in yeast to make its concentration reach 100ppm, drop in koji and bran koji to make the concentration of both reach 32.5ppm and 67.5ppm respectively.

[0043] 5. Fermentation stage:

[0044] a) Place the fermenter filled with sweet corn fermentation liquid in a normal temperature environm...

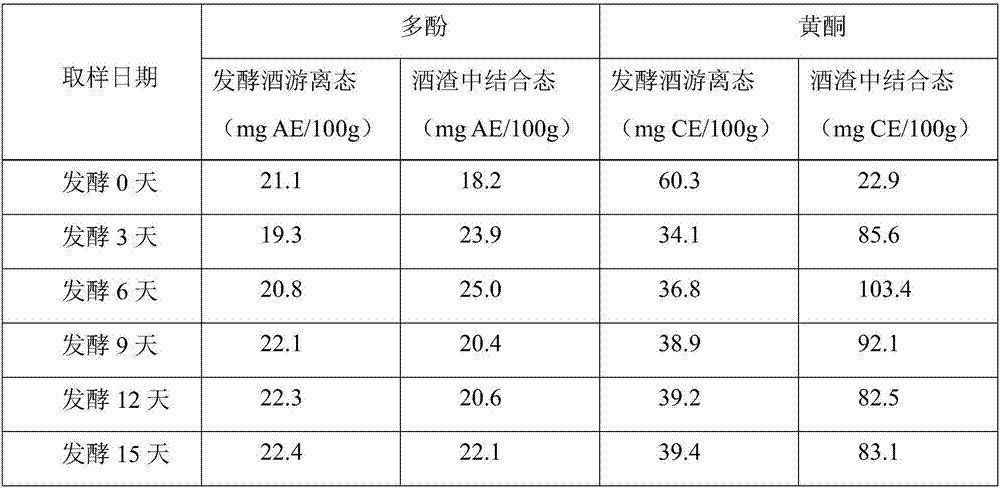

Embodiment 2

[0052] 1. Sweet corn pretreatment: Screen high-quality sweet corn, peel and wash, and then thresh. The corn kernels were collected and packed in fresh-keeping bags, and stored in a -80°C refrigerator for later use.

[0053] 2. Homogenizing corn kernels: mix 2 kg of sweet corn kernels with distilled water at a material weight ratio of 1:1, beat with a mixer, and transfer to a fermentation tank. The total volume of the obtained corn slurry accounts for 80% of the volume of the fermentation tank . No need to add pectinase and cellulase.

[0054] 3. Adjustment of sugar content: Add white granulated sugar and adjust the sugar content to 150g / L.

[0055] 4. Fermentation strain inoculation: drop in yeast to make its concentration reach 150ppm, drop in koji and bran koji to make the concentration of both reach 32.5ppm and 67.5ppm respectively.

[0056] 5. Fermentation stage:

[0057] a) Place the fermenter filled with sweet corn fermentation liquid in a normal temperature environm...

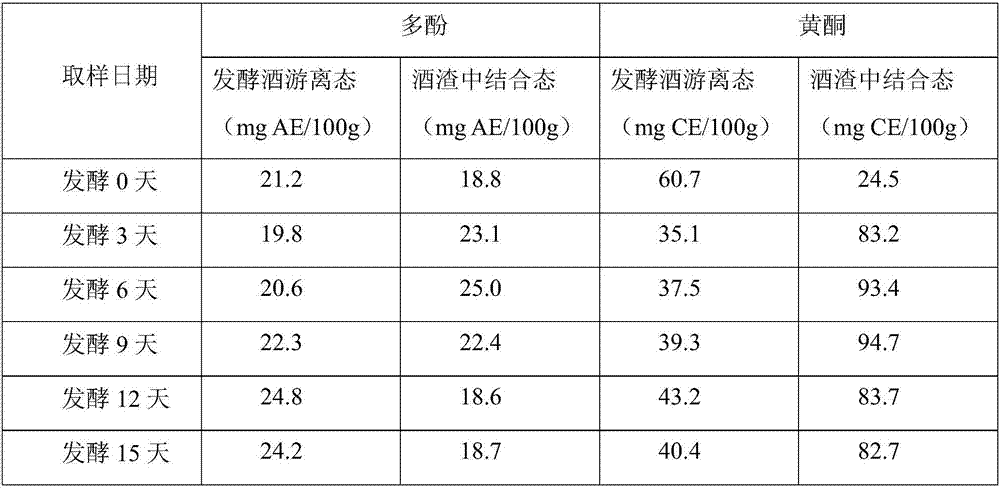

Embodiment 3

[0065] 1. Sweet corn pretreatment: Screen high-quality sweet corn, peel and wash, and then thresh. The corn kernels were collected and packed in fresh-keeping bags, and stored in a -80°C refrigerator for later use.

[0066] 2. Homogenizing corn kernels: mix 2 kg of sweet corn kernels with distilled water at a material weight ratio of 1:1, beat with a mixer, and transfer to a fermentation tank. The total volume of the obtained corn slurry accounts for 80% of the volume of the fermentation tank . No need to add pectinase and cellulase.

[0067] 3. Adjustment of sugar content: Add white granulated sugar and adjust the sugar content to 100g / L.

[0068] 4. Fermentation strain inoculation: drop in yeast to make its concentration reach 150ppm, drop in koji and bran koji to make the concentration of both reach 32.5ppm and 67.5ppm respectively.

[0069] 5. Fermentation stage:

[0070] a) Place the fermenter filled with sweet corn fermentation liquid in a normal temperature environm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com