Preparation method of AuCu-FeMoS electrocatalyst for nitrogen reduction

An aucu-femos and electrocatalyst technology, applied in the direction of electrodes, electrolysis processes, electrolysis components, etc., to reduce energy consumption and environmental pollution, improve nitrogen reduction yield and product selectivity, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

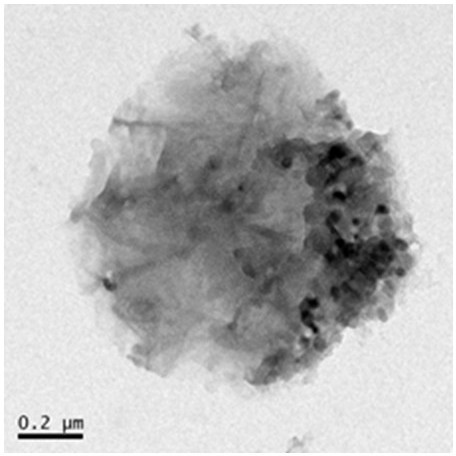

[0019] Prepare 2 mL of a mixed solution of hexane and oleylamine at a volume ratio of 1:1, take 9.88 mg of tetrachloroauric acid hydrate and 1.33 mg of cuprous chloride in the mixed solution, stir rapidly to form a homogeneous solution, and dissolve the mixture in advance at room temperature. The prepared 1.4 mL volume ratio of 2:5 triisopropylsilane and hexane mixed solution was added to the above homogeneous solution, and it was left to stand at 60 °C until the color of the solution turned black and red to obtain the AuCu alloy nanowire catalyst. Depend on figure 1 It can be seen that the AuCu alloy nanowire catalyst prepared in this example has good flexibility, the diameter is as thin as 1.2 nm, and the length is several microns.

[0020] Dissolve 0.125 g of sodium molybdate hydrate and 0.21 g of ferric nitrate hydrate in 20 mL of water, and keep the pH value of the solution at 6.5, then add 0.5 g of L-cysteine and 50 mL of water and stir for 30 minutes to form a uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com