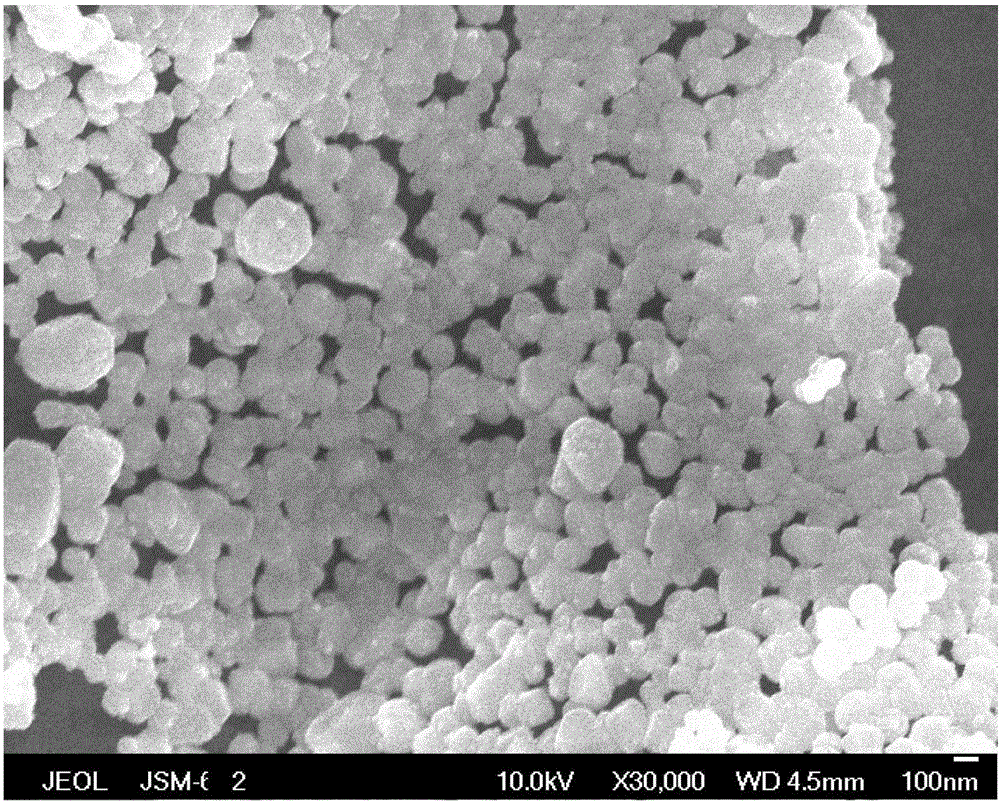

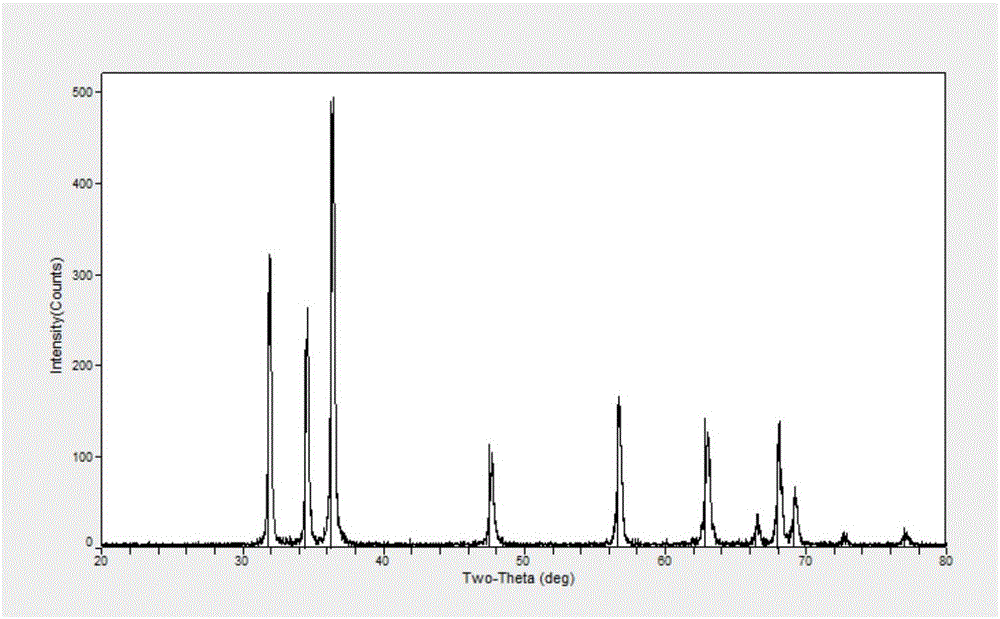

Preparation method of doped nanometer zinc oxide and application of doped nanometer zinc oxide in photocatalysis

A nano-zinc oxide and photocatalyst technology, applied in the field of inorganic nano-material preparation and photocatalysis, can solve the problems of long production time, high raw material cost, easy agglomeration of particles, etc., and achieves low production cost, low price and simple operating conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 5.0g of PVA into a 500ml round bottom flask, add 250ml of deionized water, then put the flask into a 75°C water bath and heat and stir for 1h to obtain a clear and transparent PVA aqueous solution with a mass fraction of 2%. Get 4 parts of the PVA aqueous solution of 50ml volume, add 4g Zn (NO 3 ) 2 ·6H 2 O, and add 0.04g, 0.08g, 0.20g Al(NO 3 ) 3 9H 2 O, the fourth part is not added. The mass ratio of polyvinyl alcohol to zinc nitrate is 1:4, and the mass fraction of doped aluminum nitrate nonahydrate relative to zinc nitrate hexahydrate is 1% to 5%. After mixing evenly, polyvinyl alcohol-zinc nitrate-aluminum nitrate is obtained Pour the mixed aqueous solution obtained above into the sample tray of the lyophilizer, fully pre-freeze at a low temperature, and then place it in a vacuum freeze dryer with a cold trap temperature of -55 ° C and a working pressure of 10 Pa. After drying for 10 hours, a thin layer of foamy solid was obtained; the above solid was p...

Embodiment 2, Embodiment 3

[0028] Repeat Example 1, but Al(NO 3 ) 3 9H 2 Replace O with Ce(NO 3 ) 3 ·6H 2 O, La(NO 3 ) 3 ·6H 2 O.

Embodiment 4

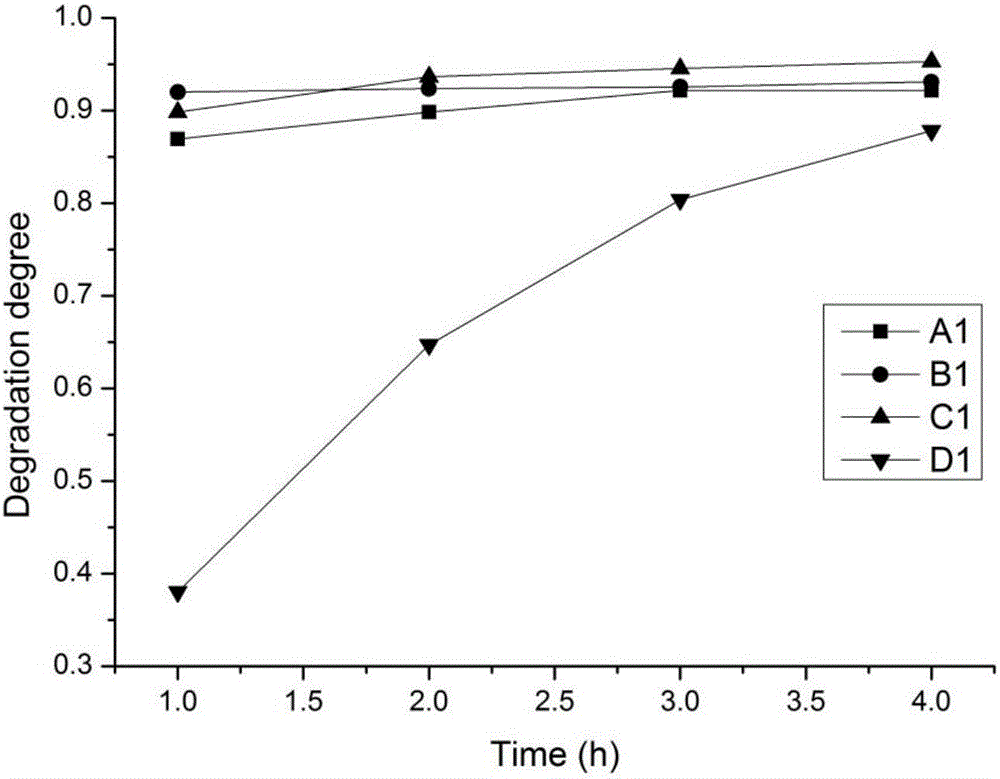

[0030]Prepare 4 parts of 60ml reactive brilliant blue KN-R solution with a mass fraction of 60mg / l, and place them in 100ml beakers numbered A1, B1, C1, and D1 respectively. In A1, B1, C1 beakers, add aluminum-doped nano-zinc oxide photocatalyst 108mg (reactive brilliant blue KN-R and catalyst mass ratio are 1:30) described in embodiment 1 respectively, correspond to Al in embodiment 1 respectively ( NO 3 ) 3 9H 2 The amount of O added is 0.04g-A1, 0.08g-B1, 0.20g-C1; the above four beakers are placed under the irradiation of a 40W ultraviolet lamp (main wavelength 365nm) (the height of the lamp tube is about 10cm from the liquid surface), at room temperature Experiment of photocatalytic degradation of reactive brilliant blue KN-R. Sample 3ml every 1h, centrifuge at 3600rpm for 15min in a centrifuge, take the supernatant, and measure its absorbance with a UV-Vis spectrophotometer. Calculate the photocatalytic degradation rate under different time, the calculation formula i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com