Preparation method of porous perfluorinated sulfonic acid resin for catalysts

A perfluorosulfonic acid resin and catalyst technology, which is applied in the preparation of organic compounds, the preparation of carboxylic acid esters, chemical instruments and methods, etc., can solve the problems of loss of effective components, decreased service life of catalysts, and increased difficulty of catalyst preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0008] A kind of preparation method of porous perfluorosulfonic acid resin for catalyst, comprises the steps:

[0009] (1) Mix the porogen with the dispersion medium, the mass ratio of the porogen to the dispersion medium is 1:(2~32), keep the temperature at 80~150℃ and the pressure 0.1~1.0MPa at a constant temperature of 2~8 hour, the porogen dispersion was obtained;

[0010] (2) Mix the porogen dispersion prepared in step (1) with perfluorosulfonyl vinyl ether, solvent, and initiator, and the porogen dispersion, perfluorosulfonyl vinyl ether, solvent, and initiator The mass ratio is (1~20):(3~19):(0~14):(2×10 -5 ~2×10 -4 ), feed tetrafluoroethylene to maintain a reaction pressure of 200 to 2000kpa, and conduct a polymerization reaction for 1 to 8 hours at a reaction temperature of 10 to 80°C to obtain a polymer feed liquid;

[0011] (3) Add deionized water and dispersant to the polymer liquid prepared in step (2), heat to 90-100°C, stir and distill for 1-4 hours, and filt...

specific Embodiment approach

[0034] Now, the present invention will be described in further detail with reference to the following examples, but the present invention is not limited to these examples.

[0035] In the following examples, all percentages are by weight unless otherwise stated. In the present invention, the EW value of the product is measured by an acid-base titration method, the melt index of the product is measured by a melt indexer, the pore size is measured by a scanning electron microscope, and the particle size is determined by a sieving method. The thermal decomposition temperature of the product was analyzed by thermogravimetric method.

[0036] raw material source

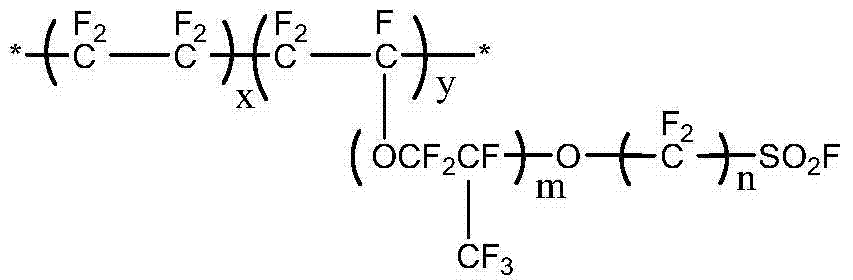

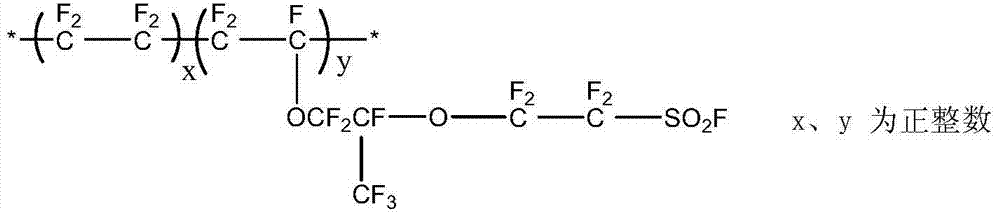

[0037] The porogen A described in the embodiment has an Ew of 870, a molecular weight of 100,000, and a structural formula as follows:

[0038]

[0039] The preparation method of porogen A:

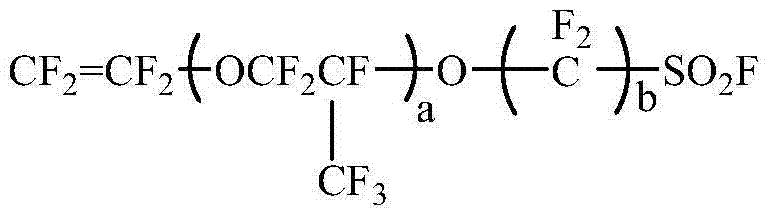

[0040] Add 150g of perfluorosulfonyl vinyl ether (LSPSVE), 650g of water (which contains 2g of perfluorooctanoic acid ammoniu...

Embodiment 1

[0053] A kind of preparation method of porous perfluorosulfonic acid resin for catalyst, comprises the steps:

[0054] (1) Take 125g of perfluoroheptane and 25g of porogen A into a 300ml autoclave, stir and heat in an oil bath to 120°C, keep the temperature for 1 hour, and cool to room temperature to obtain a solid content of 17wt%. Color transparent porogen A dispersion;

[0055] (2) Add 450g of perfluorosulfonyl vinyl ether (LSPSVE) to a 2L stainless steel reactor at room temperature, add 150g of porogen A dispersion, 1g of isopropyl peroxydicarbonate, and add 900g of perfluoroheptane. Replace with nitrogen and then replace with TFE, then pass through TFE (tetrafluoroethylene) to pressurize, raise the temperature to 70°C, adjust the pressure to keep the pressure of TFE at 650kpa, react for 1.5 hours, cool down, exhaust and discharge, and obtain a polymer Material liquid;

[0056] (3) Add 4000g of water and 100ml of polyvinyl alcohol solution with a mass percentage of 3% to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com