Method for preparing high-performance AZO transparent conductive thin film

A transparent conductive film, high-performance technology, applied in the field of AZO film and transparent conductive oxide film, can solve the problems that are difficult to meet the requirements of practical applications, the improvement of AZO film performance is not uniform, and does not have the conditions for wide promotion, etc., to achieve Realize large-scale industrial production, realize photoelectric conversion efficiency, and enhance the effect of capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

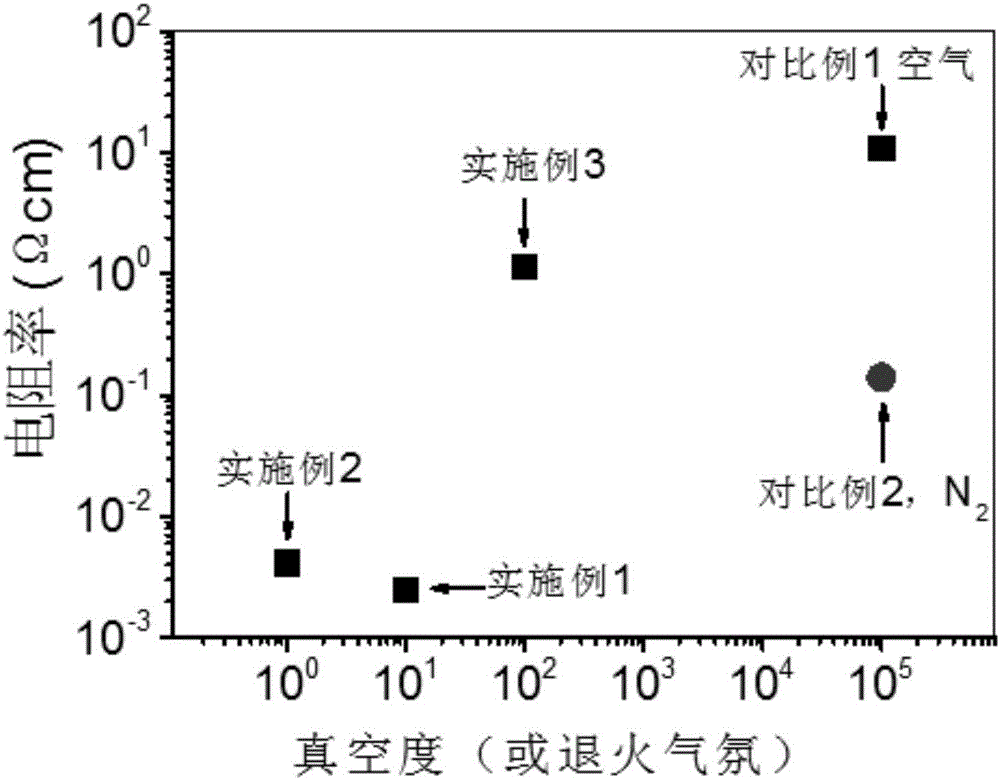

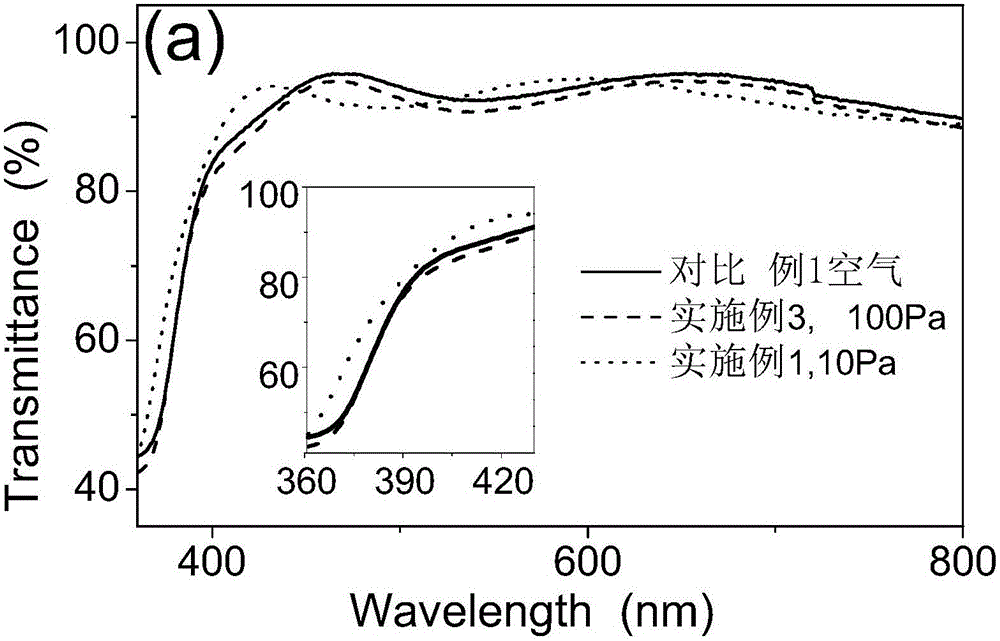

Embodiment 1

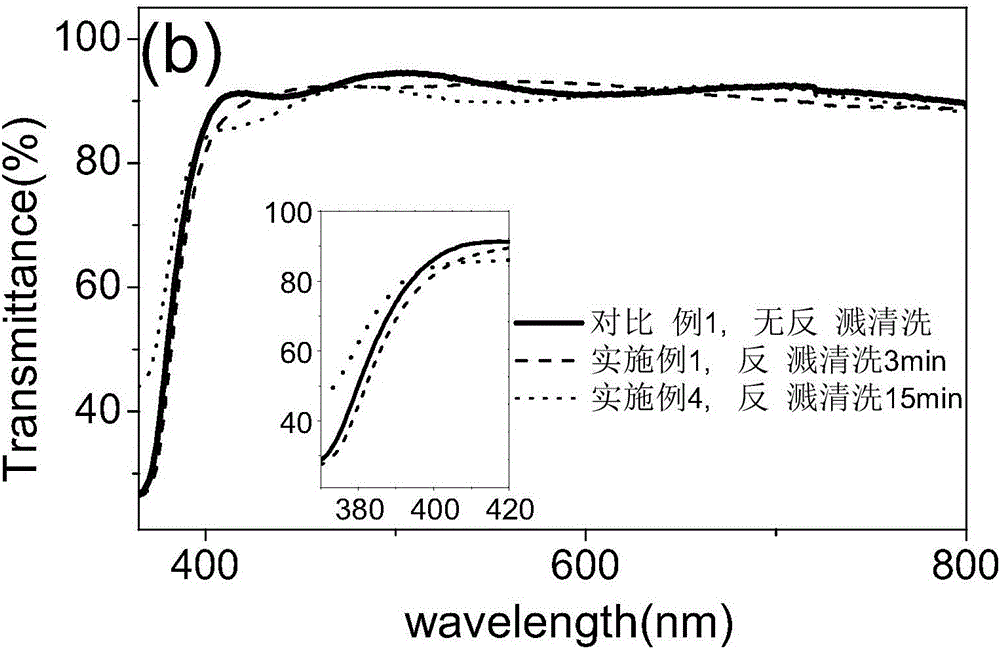

[0034] (1) Annealing under medium vacuum and using Ar + Preparation of AZO transparent conductive film by backsplash cleaning

[0035] 1) Add 0.06 mol of zinc acetate dihydrate particles into a beaker filled with 100 ml of ethylene glycol methyl ether solvent, and stir at room temperature until completely dissolved. Then added to the solution with Zn 2+ Monoethanolamine in equimolar ratio is used as stabilizer, after stirring evenly, add a certain amount of aluminum nitrate particles nonahydrate to the solution, so that Al 3+ :Zn 2+ =0.02:1 (molar ratio). Next, the beaker was placed in a water bath at 75° C. and stirred at constant temperature for 3 hours to obtain a light yellow, uniform and transparent precursor solution.

[0036] 2) Put the precursor solution open in the air and age for 24 hours to obtain a uniform and stable precursor sol with a certain viscosity.

[0037] 3) Clean the glass substrate (quartz or silicon wafer) ultrasonically with deionized water sever...

Embodiment 2

[0049] 1)-5) The steps are the same as in (1) of Example 1, AZO film is prepared on the substrate by sol-gel spin coating method.

[0050] 6) Put the AZO film prepared by spin coating into the sampling chamber of the magnetron sputtering system, and use a common mechanical pump to pump the sampling chamber to 1 Pa and maintain it. Rapidly raise the temperature to 530°C at a rate of 15°C / min, hold and anneal for 2 hours, and cool down with the furnace.

[0051] 7) After the sample chamber returns to room temperature, inject high-purity argon gas into the sample chamber, ionize and start ignition at a vacuum of 2-5Pa, and then adjust the vacuum to 1Pa to keep the AZO film in the Ar + Clean the film surface for 3 minutes under reverse sputtering.

Embodiment 3

[0053] 1)-5) The steps are the same as in (1) of Example 1, AZO film is prepared on the substrate by sol-gel spin coating method.

[0054] 6) Put the AZO thin film prepared by spin coating into the sampling chamber of the magnetron sputtering system, and use a common mechanical pump to pump the sampling chamber to 100Pa and maintain it. Rapidly raise the temperature to 530°C at a rate of 15°C / min, hold and anneal for 2 hours, and cool down with the furnace.

[0055] 7) After the sample chamber returns to room temperature, inject high-purity argon gas into the sample chamber, ionize and start ignition at a vacuum of 2-5Pa, and then adjust the vacuum to 1Pa to keep the AZO film in the Ar + Clean the film surface for 3 minutes under reverse sputtering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com