Preparation method of nickel oxide/alumina and nickel/alumina nanometer compound microparticle

A technology of alumina nano and composite microspheres, which is applied in the preparation of nickel oxide/alumina nanocomposite microspheres and the field of nickel/alumina Poor spherical uniformity, weak combination of catalytic particles and carrier, etc., to achieve the effect of firm combination and good particle distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

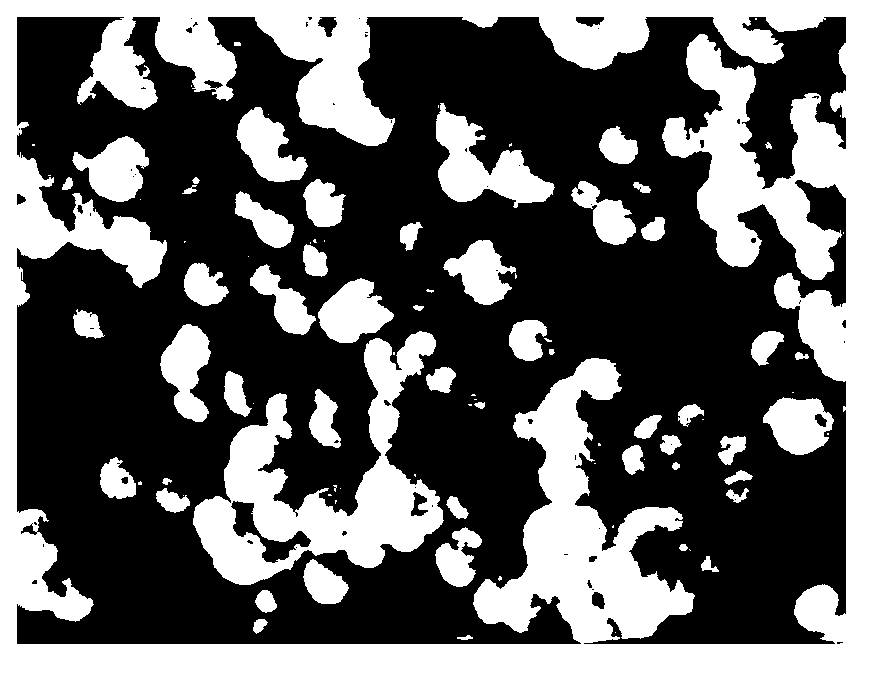

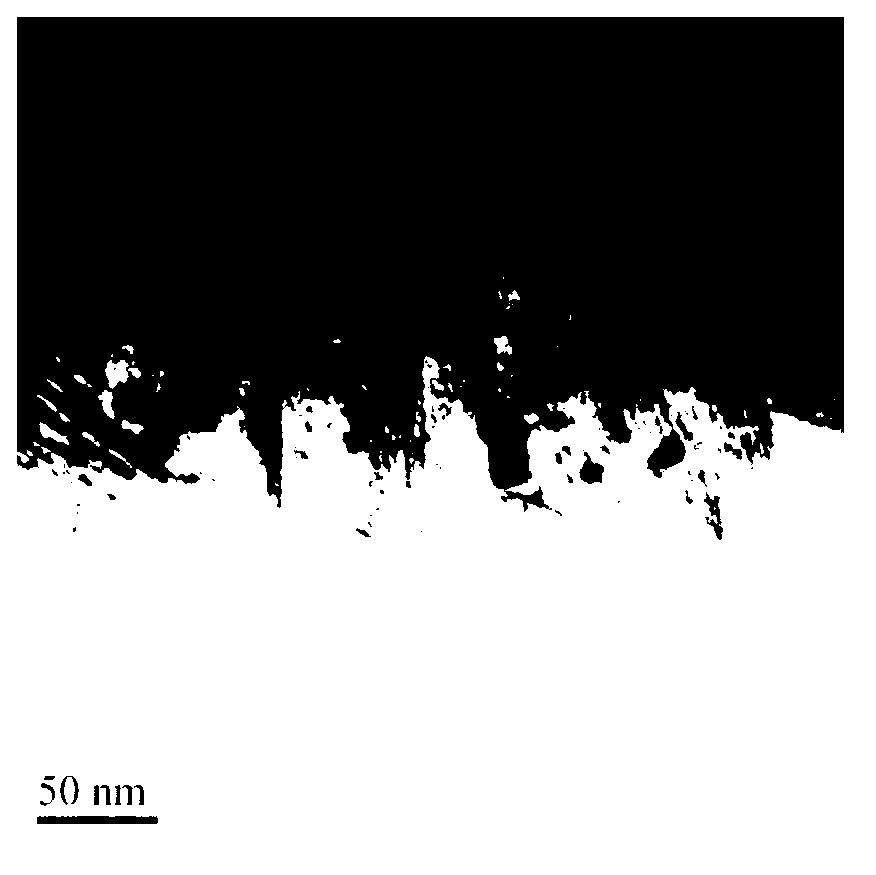

[0028] The preparation method of the nickel oxide / alumina nanocomposite microsphere of the present invention, concrete steps are as follows:

[0029] Step 1, prepare 0.03mol / L of Al(NO 3 ) 3 9H 2 0, the mixed solution of cetyltrimethylammonium bromide of 0.045mol / L and the NaOH of 1.0mol / L, solvent is the mixed solvent of deionized water and alcohol, and the volume ratio of deionized water and alcohol is 2: 1-20:1, choose methanol or n-butanol as the alcohol, then add ethyl acetate, the volume ratio of ethyl acetate to solvent is 1:10, and get a colorless transparent liquid after magnetic stirring for 30min, add 30ml colorless transparent liquid Put the solvent into a hydrothermal kettle with a polytetrafluoroethylene liner of 100ml, and then put it into the MDS-8 multi-channel closed microwave chemical station to carry out microwave hydrothermal reaction at 160°C for 60min, then centrifuge and use deionized water and Wash with absolute ethanol several times, and finally va...

Embodiment 1

[0037] Step 1, 0.35g of Al(NO 3 ) 3 9H 2 O, 0.5g of cetyltrimethylammonium bromide and 1.2g of NaOH were dissolved in 30ml of deionized water and methanol in a mixed solvent with a volume ratio of 2:1 in a stirring state, and then 3ml of ethyl acetate was added , after magnetic stirring for 30 minutes, a colorless and transparent liquid was obtained. Take 30ml of the colorless and transparent liquid and add it to a 100ml hydrothermal kettle with a polytetrafluoroethylene liner as the solvent, and then put it into the MDS-8 multi-channel closed microwave chemical station. Perform microwave hydrothermal reaction at 160°C for 60 minutes, centrifuge, wash with deionized water and absolute ethanol several times, and finally vacuum-dry at 80°C for 24 hours to obtain boehmite self-assembled microsphere powder;

[0038] Step 2, weigh 1.2g of the boehmite self-assembled microsphere powder obtained in step 1 and add it to 50ml of nickel nitrate hexahydrate solution with a concentratio...

Embodiment 2

[0041] Step 1, 0.35g of Al(NO 3 ) 3 9H 2 O, 0.5g of cetyltrimethylammonium bromide and 1.2g of NaOH were dissolved in 30ml of deionized water and methanol in a mixed solvent with a volume ratio of 10:1 in a stirring state, and then 3ml of ethyl acetate was added , after magnetic stirring for 30 minutes, a colorless and transparent liquid was obtained. Take 30ml of the colorless and transparent liquid and add it to a 100ml hydrothermal kettle with a polytetrafluoroethylene liner as the solvent, and then put it into the MDS-8 multi-channel closed microwave chemical station. Perform microwave hydrothermal reaction at 160°C for 60 minutes, centrifuge, wash with deionized water and absolute ethanol several times, and finally vacuum-dry at 80°C for 24 hours to obtain boehmite self-assembled microsphere powder;

[0042] Step 2, weigh 1.2g of the boehmite self-assembled microsphere powder obtained in step 1 and add it to 50ml of nickel nitrate hexahydrate solution with a concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com